Stereo garage stacking machine and stacking method

A technology of three-dimensional garages and stackers, applied in the field of stackers, can solve problems such as low work efficiency, low utilization rate, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

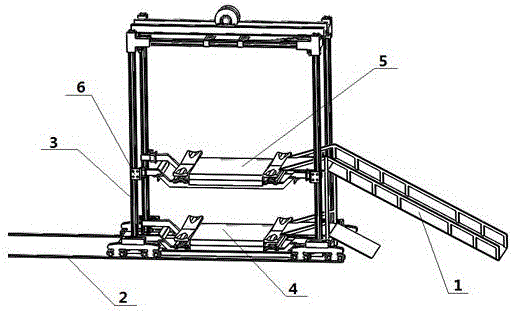

[0024] Such as figure 1 , the present invention comprises the horizontal track 2 that lays on the ground left and right, installs on the horizontal track 2 the vertical frame 3 that can move horizontally along the track 2, and connects the first layer of load-bearing mechanism 4 and the second layer of load-bearing mechanism on the vertical frame 3 Mechanism 5, the second layer of load-bearing mechanism 5 is located directly above the first layer of load-bearing mechanism 4, and has a certain distance from the gap between the first layer of load-bearing mechanism 4. The first layer of load-bearing mechanism 4 and the second layer of load-bearing mechanism 5 have the same structure, and the two are fixedly connected together. The left and right ends of the first layer of load-bearing mechanism 4 and the second layer of load-bearing mechanism 5 are slidably connected with the vertical frame 3 through the connecting block 6, and can slide up and down along the vertical frame 3 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com