Wireless acoustic emission detector of wind power generator unit

A technology for wind turbines and detection devices, which is applied in the monitoring of wind turbines, machines/engines, and wind turbines, can solve problems such as long distances, broken towers, false alarms, etc., so as to achieve accurate monitoring results and reduce leakage alarms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

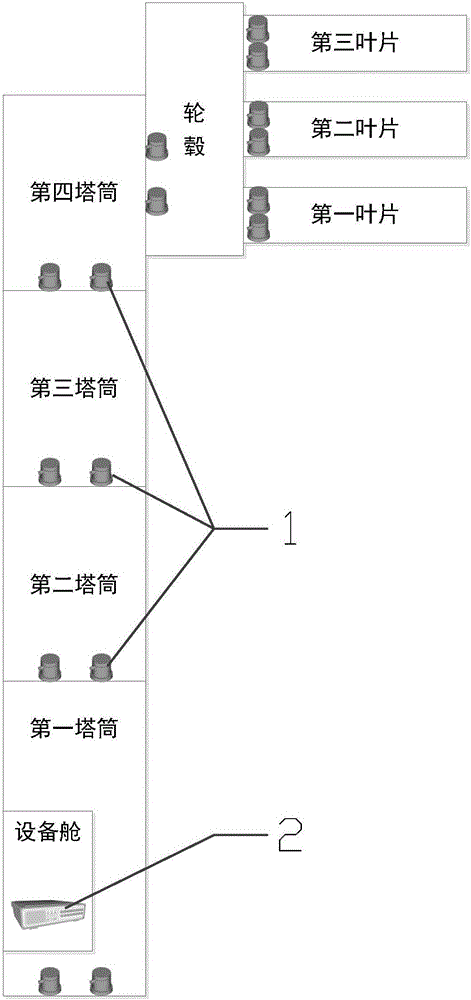

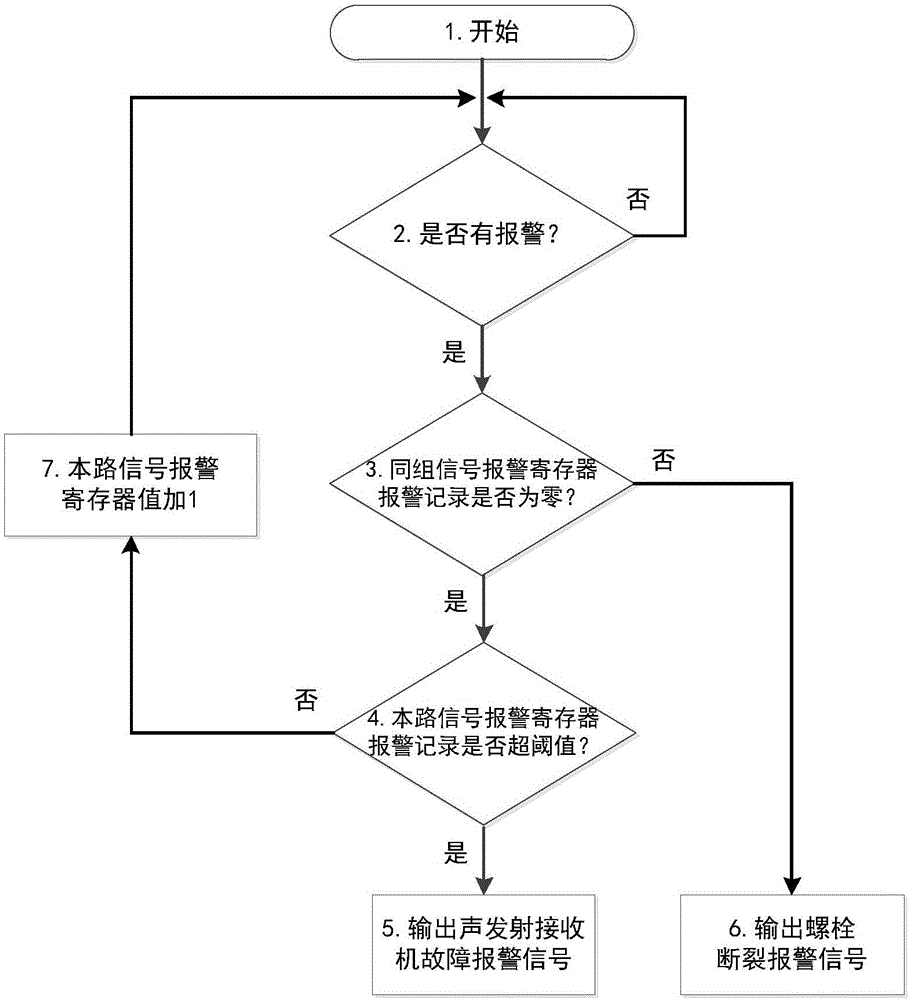

[0022] The following is attached Figures 1 to 2 , to further illustrate the specific implementation of a wireless acoustic emission detection device for wind turbines according to the present invention. A wireless acoustic emission detection device for wind turbines according to the present invention is not limited to the description of the following embodiments.

[0023] Such as figure 1 As shown, it is a schematic diagram of the overall structure of a wireless acoustic emission detection device for wind turbines according to the present invention, including an acoustic emission receiver 1 for collecting, amplifying and extracting characteristic parameters of bolt fracture acoustic emission signals of wind turbines, and for extracting The host 2 for analyzing and recording the characteristic parameters of the acoustic emission signal, making logical judgments and displaying alarms. The acoustic emission receiver 1 and the host 2 are also provided with a communication modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com