Anti-run-out water gate capable of being automatically closed and opened

An automatic shut-off and anti-running water technology, which is applied in the direction of engine components, function valve types, lift valves, etc., can solve the problems of high machining accuracy requirements for components, increased faucet volume, and increased production costs. Production, easy installation and dismantling, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

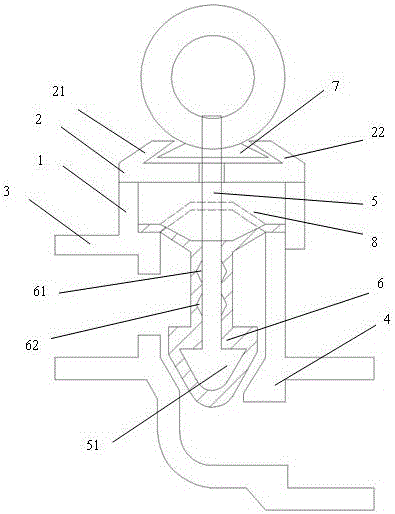

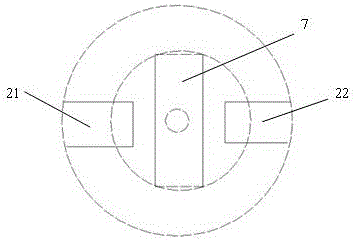

[0037] 2. In further embodiments of the present invention, please continue to refer to figure 1 As shown, the reset silica gel 6 is also provided with an annular groove 61 and an annular groove 62 on the contact surface. When the gate pin 5 is pulled out, the annular groove 61 and the annular groove 62 form folds. 61 and the groove 62 can make the gate pin 5 move up and down better, and reduce the wear and aging of the reset silica gel 6 at the same time.

[0038] In a further embodiment of the present invention, both the cover plate 2 and the handle 7 are made of transparent material, and the internal structure of the present invention can be observed through the cover plate 2. If the internal structure is damaged or malfunctioned, it is convenient to open the cover plate for maintenance or replacement.

[0039] In a further embodiment of the present invention, the lower end of the cover plate 2 forms a protrusion (not shown in the figure) downwards, and the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com