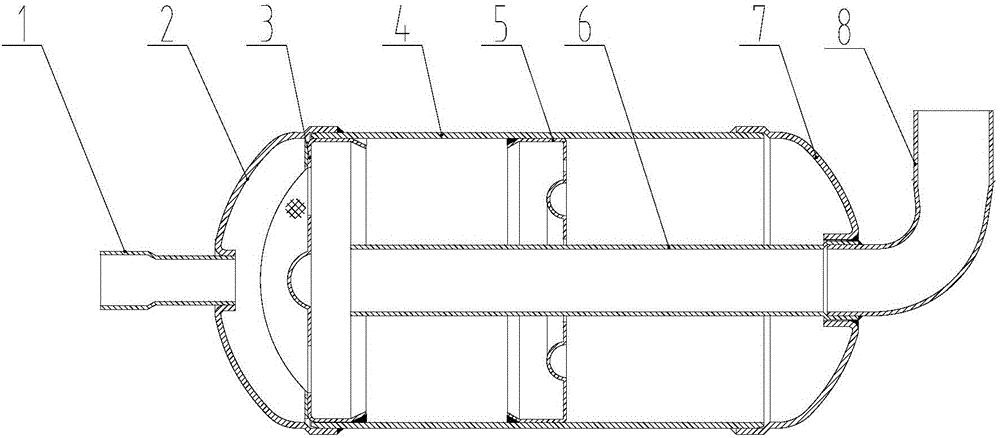

Liquid distributor and compressor system

A liquid separator and auxiliary pipe technology, which is applied in the field of compressor systems, can solve the problems of large number of liquid separators, inability to meet quick installation, and low degree of generalization, so as to meet replacement requirements, fast installation, and increase versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

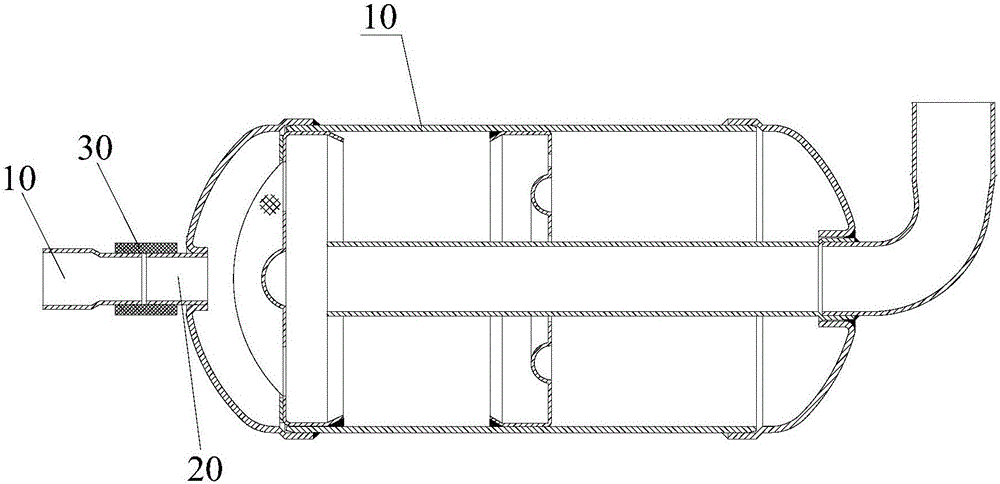

[0016] see figure 2 As shown, according to the embodiment of the present invention, a liquid separator is provided, which is especially suitable for the use of compressors in air-conditioning systems. The liquid separator of this embodiment includes a housing 10 with an internal space, an auxiliary pipe 20 and an adapter pipe 30 , the auxiliary pipe 20 is fixedly connected to the housing 10 , and the first end of the auxiliary pipe 20 communicates with the internal space. The first end of the transfer pipe 30 is connected to the second end of the auxiliary pipe 20 , the second end of the transfer pipe 30 is connected to the suction pipe 40 of different diameters, and the suction pipe 40 communicates with the auxiliary pipe 20 through the transfer pipe 30 .

[0017] The liquid distrib...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap