Absolute linear time grating displacement sensor based on alternating electric field

A technology of displacement sensor and alternating electric field, which is applied in the direction of converting sensor output, instruments, and electrical devices, etc., to achieve the effects of improving stability, simple structure, and suppressing common-mode interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

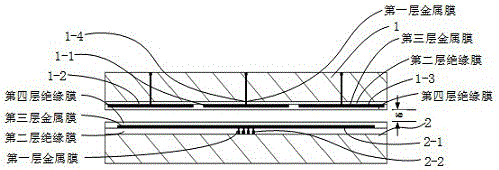

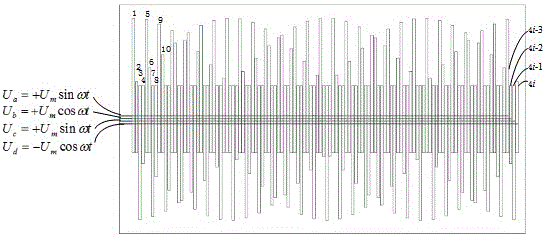

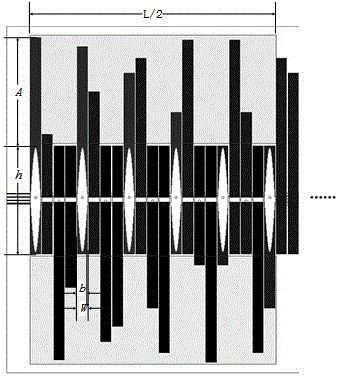

[0030] Figure 1(a), Figure 1(b), figure 2 , image 3 As shown, the sensor of the present invention includes two parts: a probe base (1) and a scale base (2). Ceramics are used as the base material, and the upper surface of the fixed-length base is covered with four dielectric films in sequence, the first layer is a metal film, the second layer is an insulating film, the third layer is a metal film, and the fourth layer is an insulating protective film. The first layer of metal film is 4 flat strip wires located under the electrodes, that is, 4 excitation signal leads (2-2), which are respectively used to connect the corresponding electrode strips of the excitation electrodes A, B, C, and D into a group. The third layer of metal film is covered with four sets of excitation electrodes A, B, C, and D. The width of each el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com