Terahertz graphene microstructure modulator

A microstructure and graphene technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of poor electronic control tunability and large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

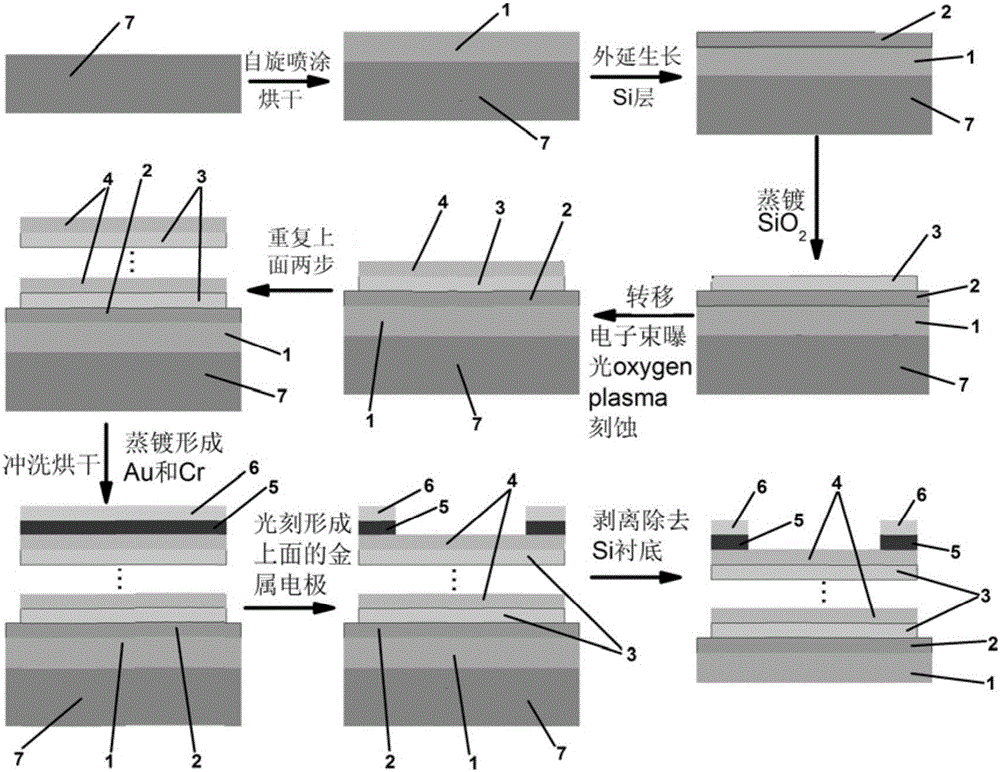

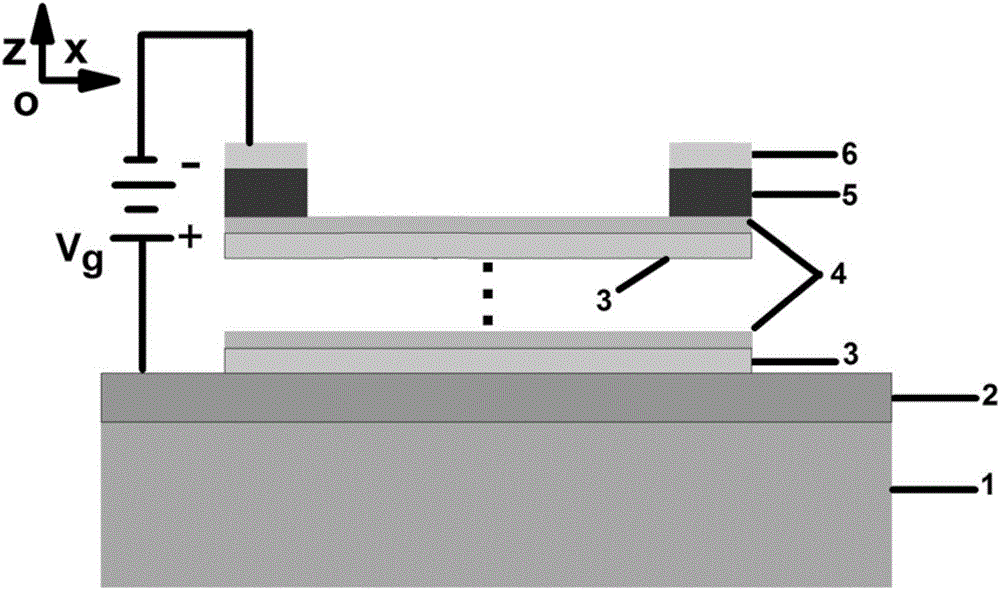

[0043] refer to figure 1 , the fabrication method of the terahertz wave graphene complementary microstructure modulator of the present invention is as follows:

[0044] Step 1, making a flexible substrate

[0045] A common Si sheet is used as the sacrificial layer 7, and the solution containing the plastic flexible substrate 1 is sprayed on it by spin coating, and then dried in an oven for about 30 minutes. The temperature range in the oven is 150-200 ℃, and then use a high temperature furnace in an inert gas (or N 2 ) in a protective atmosphere to 300-400 ° C to form a uniform thin layer of flexible substrate.

[0046] In order to reduce the influence of the flexible substrate, its thickness is controlled at about 1-10 μm, preferably less than 5 μm.

[0047] Step 2, making an epitaxial layer doped with Si

[0048] A doped Si layer 2 with a thickness of 1-10 μm is formed by an epitaxial growth method, and the doping concentration is 2×10 16 cm -3, The electrical conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com