Robot welding signal collection multi-channel converter

A technology for robotic welding and signal acquisition, applied in instruments, simulators, manipulators, etc., can solve the problems of high manufacturing cost, time-consuming, and difficulty in equipment maintenance and replacement, and achieve the effect of small equipment and convenient operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

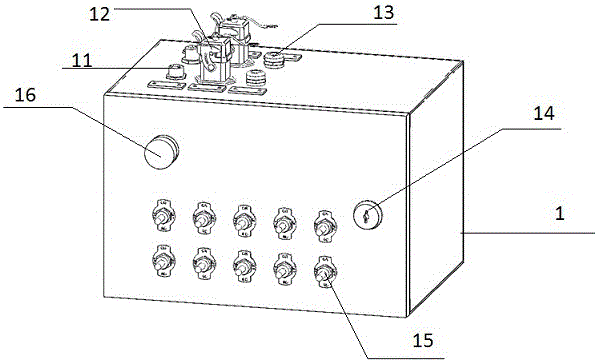

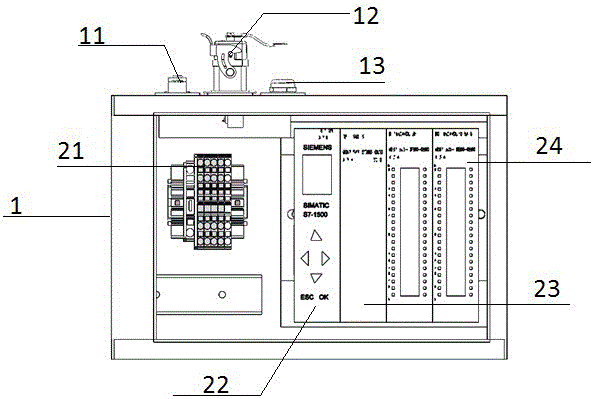

[0019] Combine below figure 1 with figure 2 , the present invention is further described:

[0020] Such as figure 1 As shown, a robot welding signal acquisition multi-channel converter includes a cabinet body 1, a DC24V power supply access terminal 11, an Ethernet communication interface 12, and a PROFIBUS-PA communication interface 13 are arranged on the top of the cabinet body. The side wall of body 1 is also provided with a plurality of signal control switches 15, and cabinet door lock 14 and power indicator light 16 are also established on the side wall of cabinet body 1.

[0021] Also includes a counter, coupled to the programmable controller 22, which is used to calculate the number of abnormal situations experienced by the plurality of interfaces and the modules; when the number reaches a preset value, the programmable controller Device 22 sends an alarm signal.

[0022] Such as figure 2 As shown, a robot welding signal acquisition multi-channel converter is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com