Touch panel and making method thereof and touch device

A touch panel, non-touch technology, applied in instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems affecting product yield, weak anti-static ability, and high impedance of metal bridge wires. Achieve the effect of reducing electrostatic breakdown, preventing electrostatic breakdown connecting bridges, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

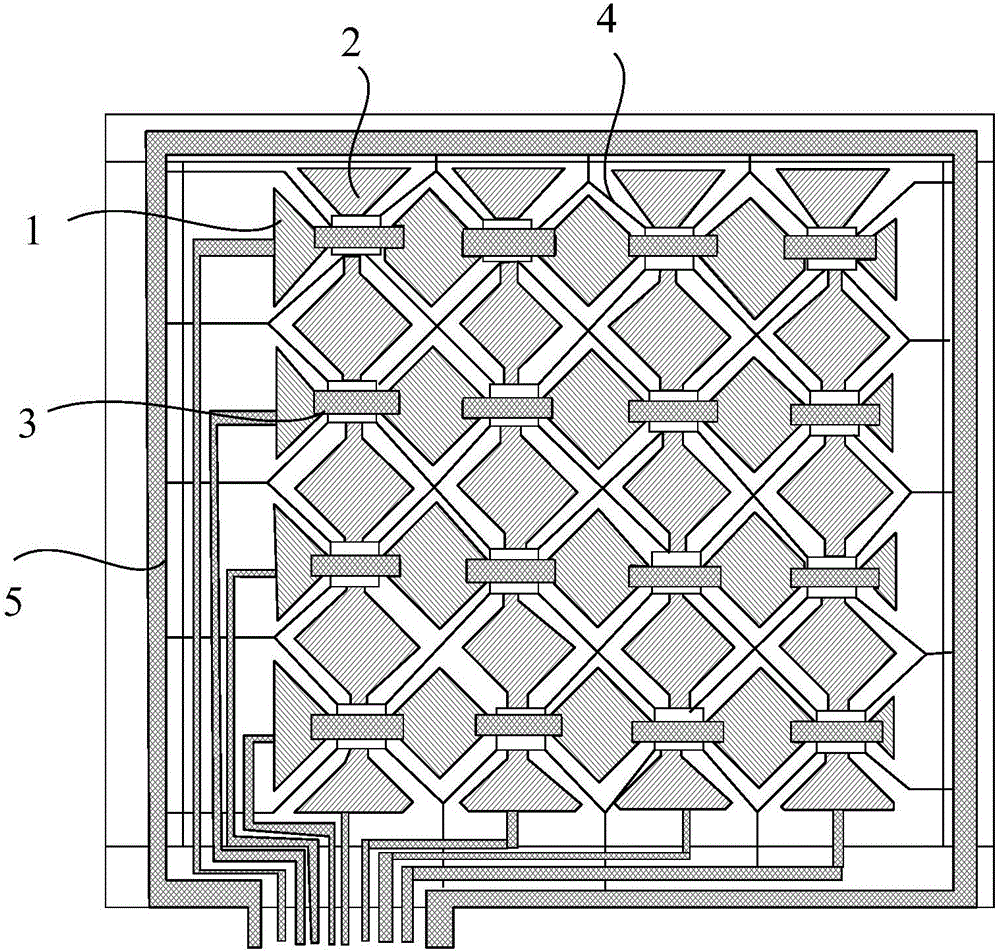

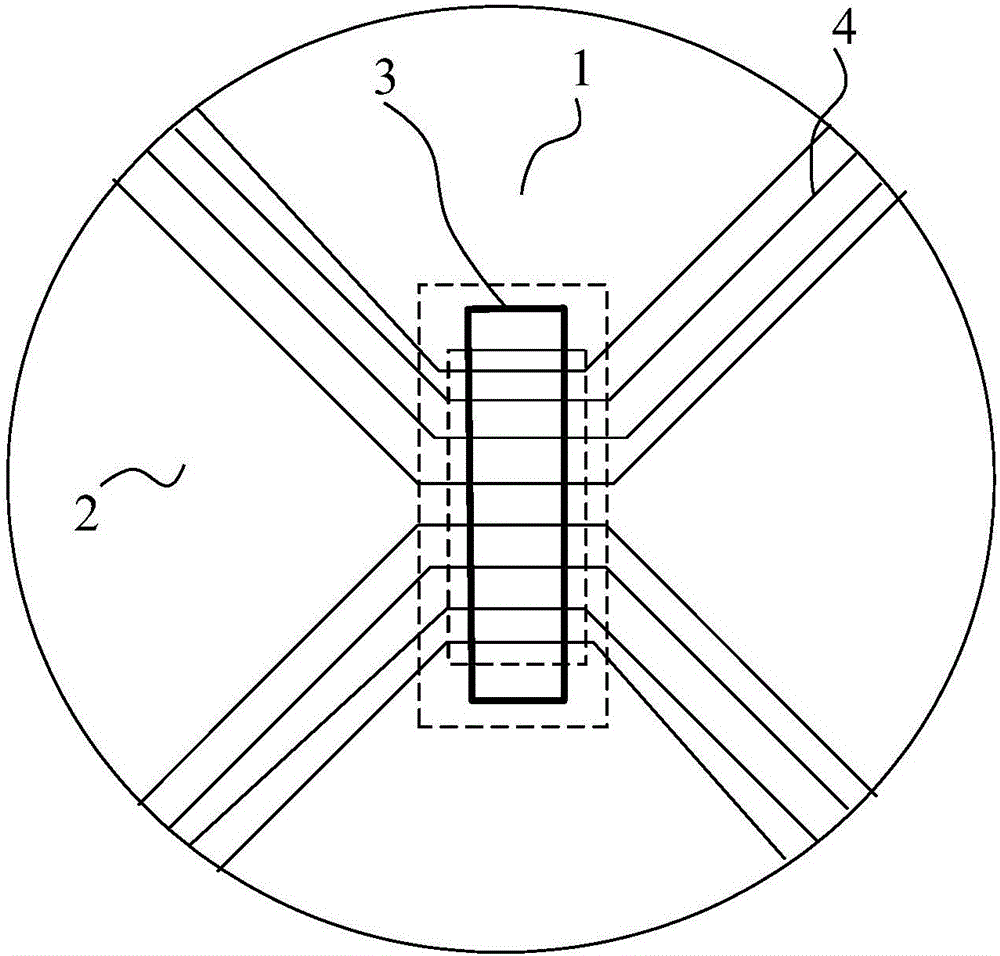

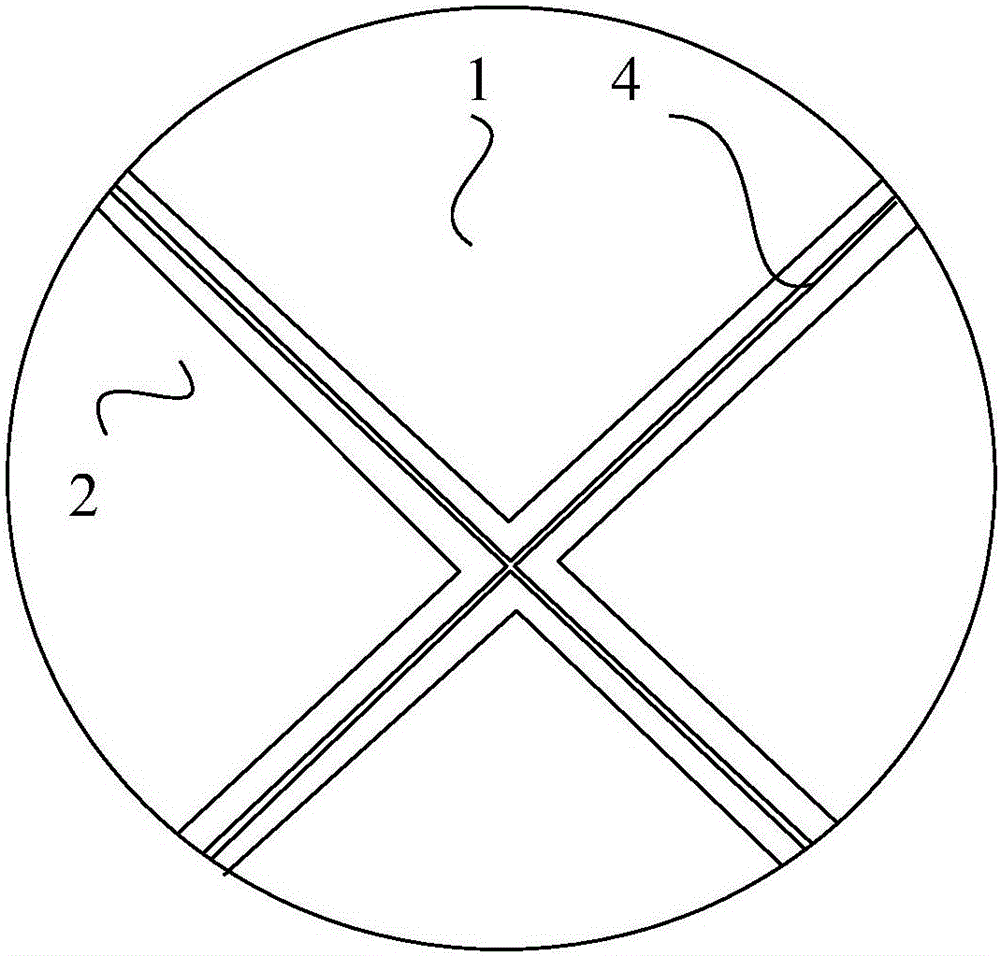

[0032] Such as figure 1 as shown, figure 1 Schematic diagram of the structure of the touch panel provided by the embodiment of the present invention; the present invention provides a touch panel, including: the first electrode and the second electrode located on the same layer and intersecting each other in the touch area, located in the non-touch area The ground wiring in the control area, wherein: the first electrode includes a plurality of first sub-electrode blocks 1 arranged along the first direction, the second electrode includes a plurality of second sub-electrode blocks 2 arranged along the second direction, and along In the second direction, any two adjacent second sub-electrode blocks 2 are connected to each other, along the first direction, any adjacent two first sub-electrode blocks 1 are bridged by a connecting bridge 3, the first direction and The second direction is vertical; also includes:

[0033] At least one set of electrostatic lead-out lines 4 that are i...

Embodiment 2

[0045] The present invention also provides a touch device, comprising: the touch panel described in any one of the above. Since the above-mentioned touch panel can reduce the phenomenon of electrostatic breakdown, the touch device provided by the present invention has a better yield rate.

Embodiment 3

[0047] Such as Figure 5 as shown, Figure 5 It is a flowchart of a method for manufacturing a touch panel provided by an embodiment of the present invention. The present invention also provides a method for manufacturing a touch panel, including:

[0048] Step S501: forming first electrodes and second electrodes on the same layer in the touch area and intersecting each other on the base substrate, and ground traces located in the non-touch area, wherein: the first electrode includes a plurality of edges The first sub-electrode blocks arranged in the first direction, the second electrode includes a plurality of second sub-electrode blocks arranged in the second direction, and along the second direction, any two adjacent second sub-electrode blocks are connected to each other , along the first direction, any two adjacent first sub-electrode blocks are bridged by a connecting bridge, and the first direction is perpendicular to the second direction; it also includes:

[0049] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com