Method and device for generating assembly dimensional chain

A technology of assembly size and size, applied in the mechanical field, can solve the problems of incomplete description, reduce the efficiency and success rate of the assembly size chain, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

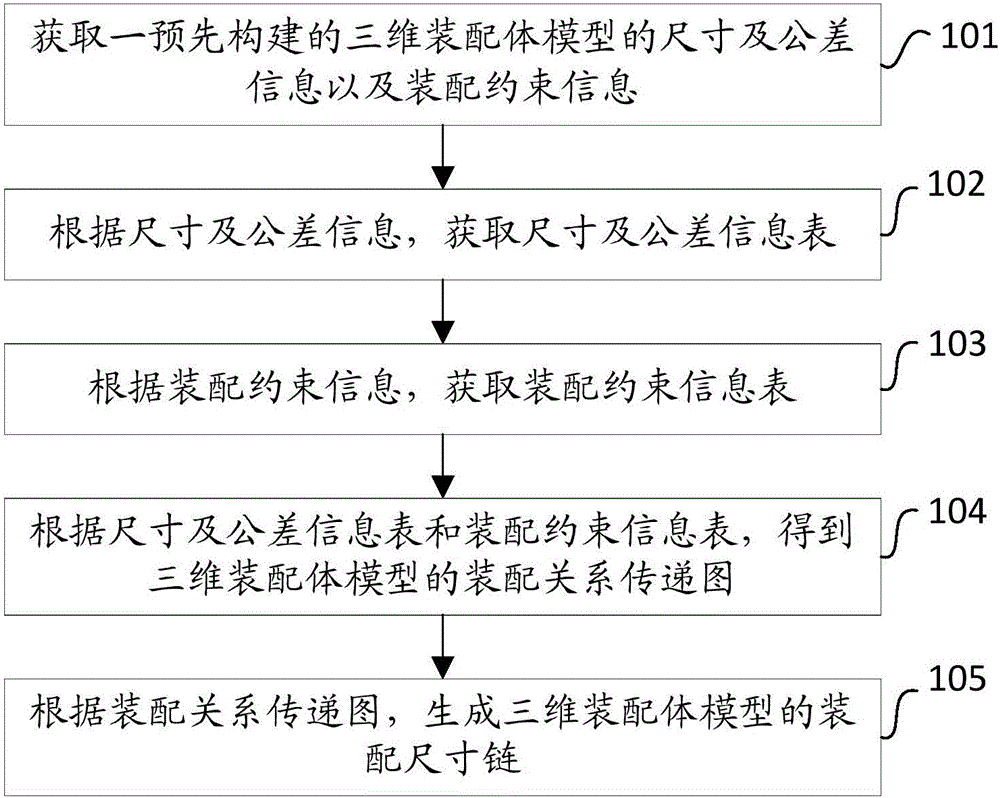

[0052] Such as figure 1 As shown, it is a flow chart of the steps of the method generated by the assembly dimension chain in the first embodiment of the present invention, including:

[0053] Step 101 , acquiring dimension and tolerance information and assembly constraint information of a pre-built 3D assembly model.

[0054] In this step, specifically, since the 3D assembly model is composed of sub-assemblies and parts, after obtaining a pre-built 3D assembly model, the 3D assembly model can be Decompose, decompose the 3D assembly model into sub-assemblies and parts, and then decompose the sub-assemblies step by step until all the parts included in the 3D assembly model are obtained, so as to obtain the dimensions and dimensions of all parts in the 3D assembly model Tolerance information and assembly constraint information.

[0055] Step 102, according to the size and tolerance information, obtain the size and tolerance information table.

[0056] In this step, the size an...

no. 2 example

[0071] Optionally, in order to ensure the integrity of the obtained assembly relationship transfer diagram and the success rate of assembly dimension chain generation, it is first necessary to ensure the integrity of the obtained 3D assembly model size and tolerance information and assembly constraint information. Therefore, after obtaining the size and tolerance information and assembly constraint information of the pre-built 3D assembly model, when the size and tolerance information and assembly constraint information are missing in the 3D assembly model, the missing size and assembly constraint information of the 3D assembly model can be Tolerance information and assembly constraint information are supplemented and complete.

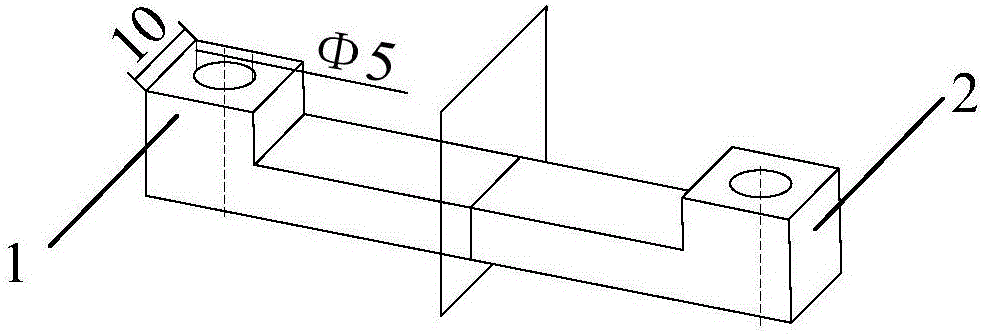

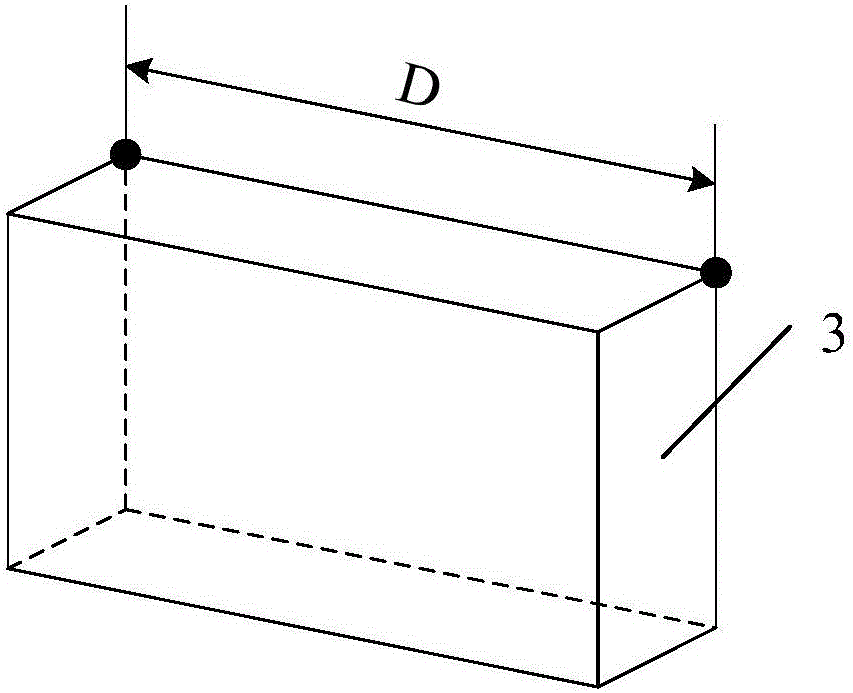

[0072] For example, if figure 2 Shown is a schematic diagram of part mirror feature replication. When building a 3D assembly model, methods such as mirroring and arraying may be used to replicate geometric features. When copying geometric features,...

no. 3 example

[0079] Such as Figure 4 As shown, in the third embodiment of the present invention, according to the size and tolerance information table and the assembly constraint information table, the flow chart of obtaining the assembly relationship transfer diagram of the three-dimensional assembly model includes:

[0080] Step 401, obtain all dimension and tolerance information tables corresponding to each part in the three-dimensional assembly model.

[0081] In this step, specifically, each size and tolerance data can determine a size and tolerance information table. Here, all the size and tolerance information tables corresponding to each part in the three-dimensional assembly model are obtained, that is, each size and the dimension and tolerance information table where the tolerance data resides.

[0082] Step 402 , according to the association relationship among the first associated geometric features in all the dimensions and tolerance information table corresponding to each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com