Body based sub assembly identification method

A technology of sub-assembly and identification method, applied in reasoning methods, instruments, manufacturing computing systems, etc., can solve problems such as combinatorial explosions, achieve the effects of reducing the scale of problems, enhancing description capabilities, and ensuring portability and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

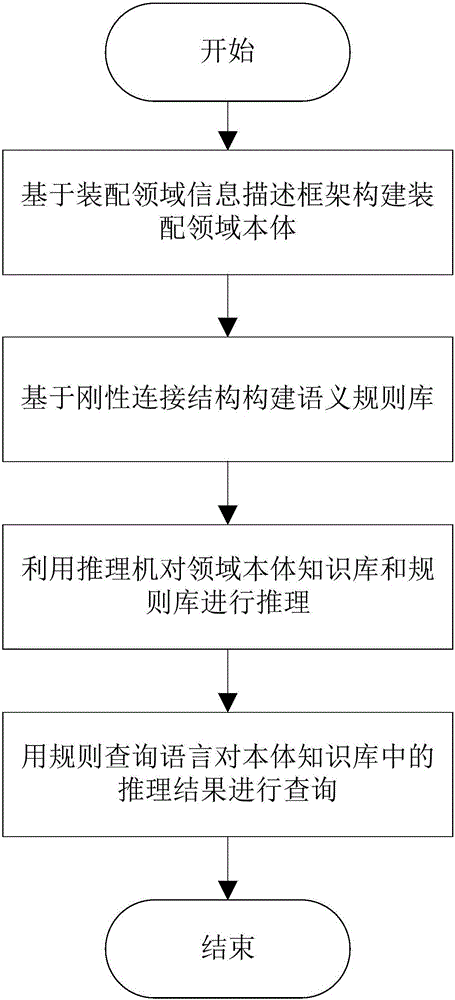

[0024] An ontology-based subassembly recognition method, such as figure 1 shown, including the following steps:

[0025] Phase 1. The construction of ontology knowledge base representation framework and the construction of semantic reasoning rule base:

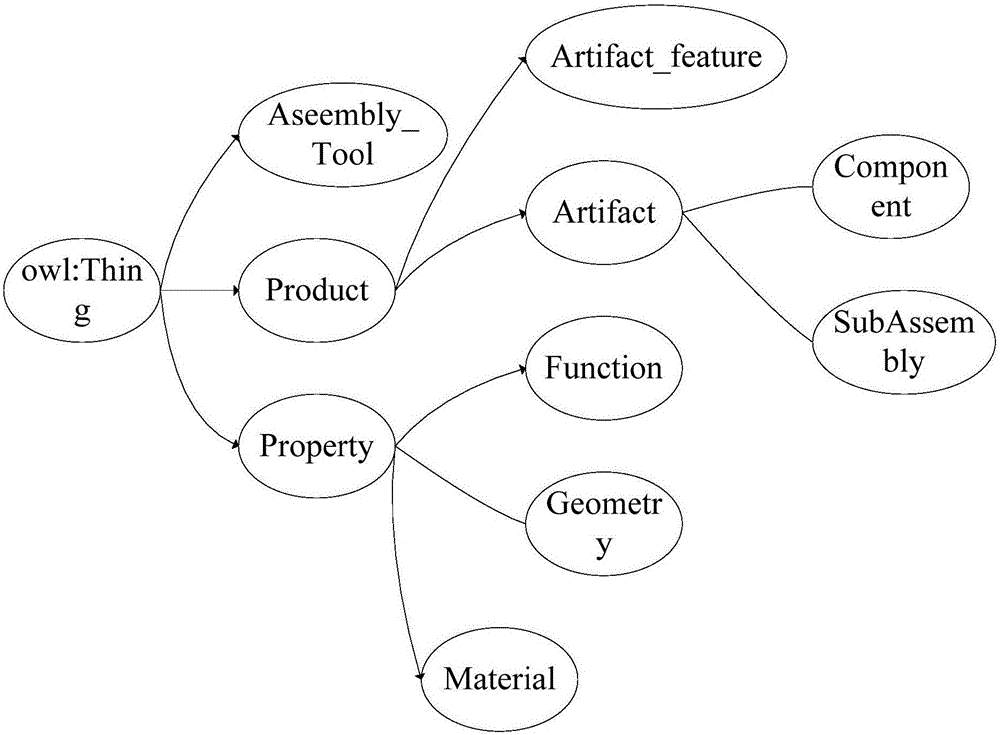

[0026] Step A. Construct the corresponding ontology knowledge base according to the assembly domain knowledge framework, and the attribute relationship between classes in the ontology provides a consistent description of the domain knowledge.

[0027] Step A1. According to the assembly domain knowledge, classes and class relationships in the process of ontology construction reflect the types of main description concepts and the containment relationship (hierarchical relationship) between concepts. Classes are mainly divided into two categories: one is physical objects, and its sub-categories mainly include parts, components, sub-assemblies, etc.; the other is feature classes, and its sub-categories mainly include geometric fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com