Rotary-drum-type isolating-switch-static-contact washing device

A technology of isolating switch and cleaning device, applied in the field of electric power system, can solve the problems of equipment outage, potential safety hazards, inconvenient manual maintenance and climbing operation, etc., and achieve the effect of safe cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with specific examples:

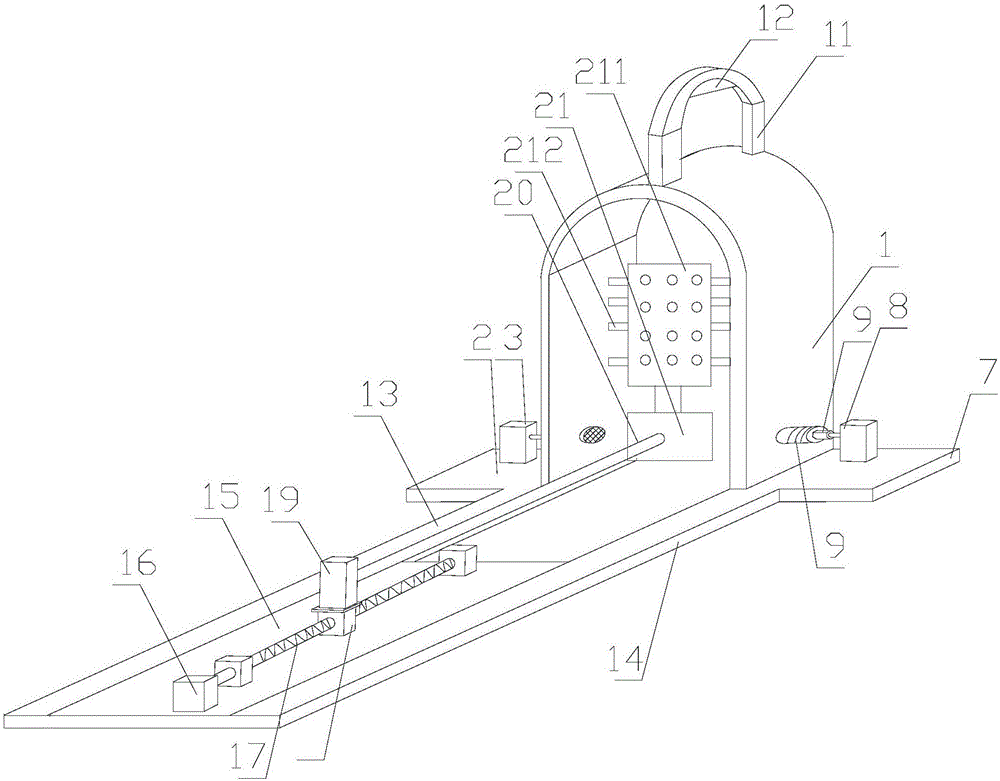

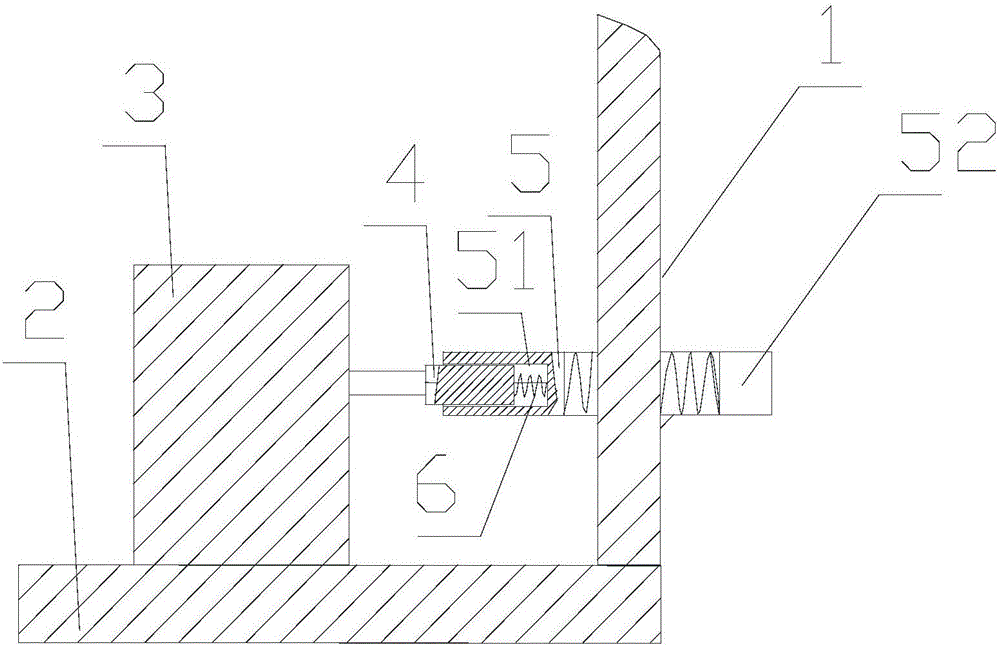

[0010] like figure 1 and figure 2 As shown, a rotary bucket type isolating switch contact cleaning device includes an inverted U-shaped contact connecting plate 1, the left bottom of the contact connecting plate 1 is provided with a first fixing plate 2 extending to the left, and the first fixing plate 2 is provided with a first remote control motor 3, the output shaft of the first remote control motor 3 is fixedly connected with a hexagonal prism-shaped first transmission column 4, and the first transmission column 4 is sleeved with a first threaded rod 5, and the first threaded rod 5 One end is provided with a hexagonal prism-shaped first connection groove 51 for socketing with the first transmission column 4, and the other end of the first threaded rod 5 is provided with a first unthreaded smooth sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com