Machining method for permanent magnetic direct current brushless motor

A brushless motor, permanent magnet DC technology, applied in electrical components, electromechanical devices, etc., can solve the problems of precise control of magnetic flux and speed, poor consistency of motor performance, uncertainty of motor speed, etc., to improve motor speed and signal distortion. The effect of reducing the resistance and weakening the running resistance of the magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

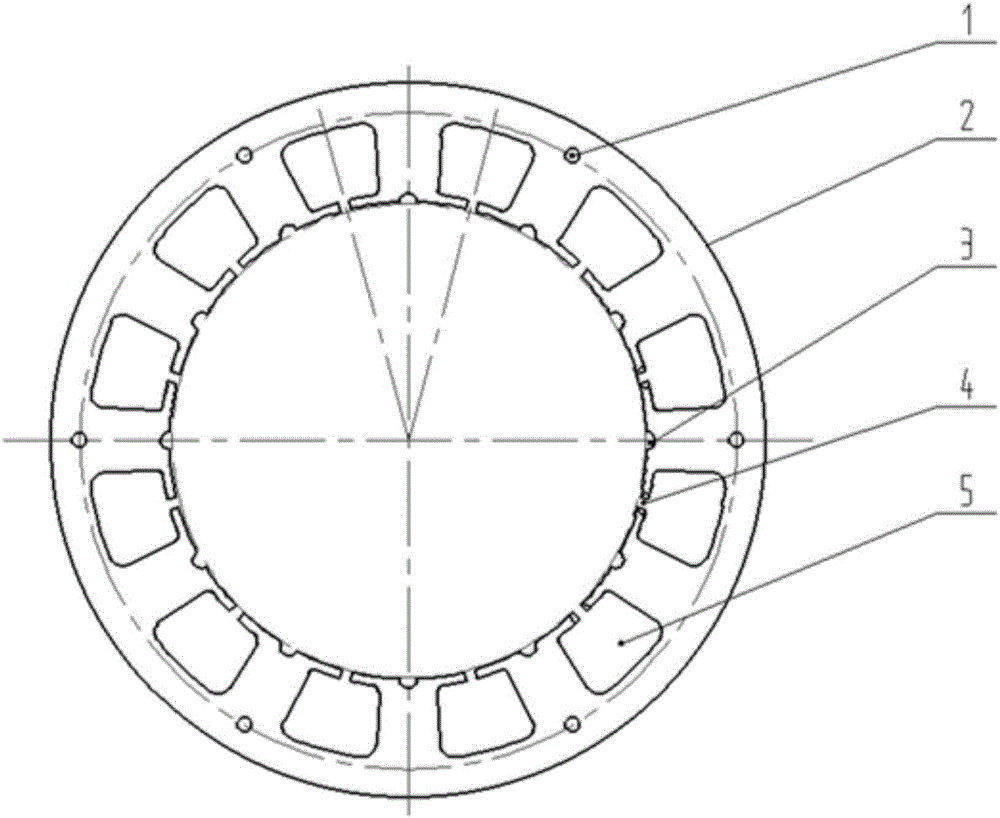

[0012] like figure 1 Shown is the structural diagram of the embodiment of the present invention, including: stator, the stator is composed of N silicon steel sheets 2 stacked, and the silicon steel sheets 2 are fixed by positioning steel nails 1; stator slots 5 are evenly distributed on the stator, and the stator slots 5 A Hall slot 4 is formed in the middle of the notch, and a Hall element is embedded in the Hall slot 4; the present invention processes a semicircular acceleration slot with magnetic flux control on the middle position of the slot teeth between two adjacent stator slots Port 3, the acceleration slot 3 with magnetic flux control forms a semicircular partition between two adjacent stator slots, and forms a local eddy current magnetic field in the acceleration slot 3 with magnetic flux control.

[0013] The stator generally has different height specifications ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap