Repelling drive circuit for H bridge of motor

A drive circuit and drive unit technology, which is applied to the starter of a single DC motor, motor generator/starter, etc., can solve the problems of damaging the H-bridge switch tube, burning out the power supply, and not designing simultaneous conduction of mutually exclusive circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

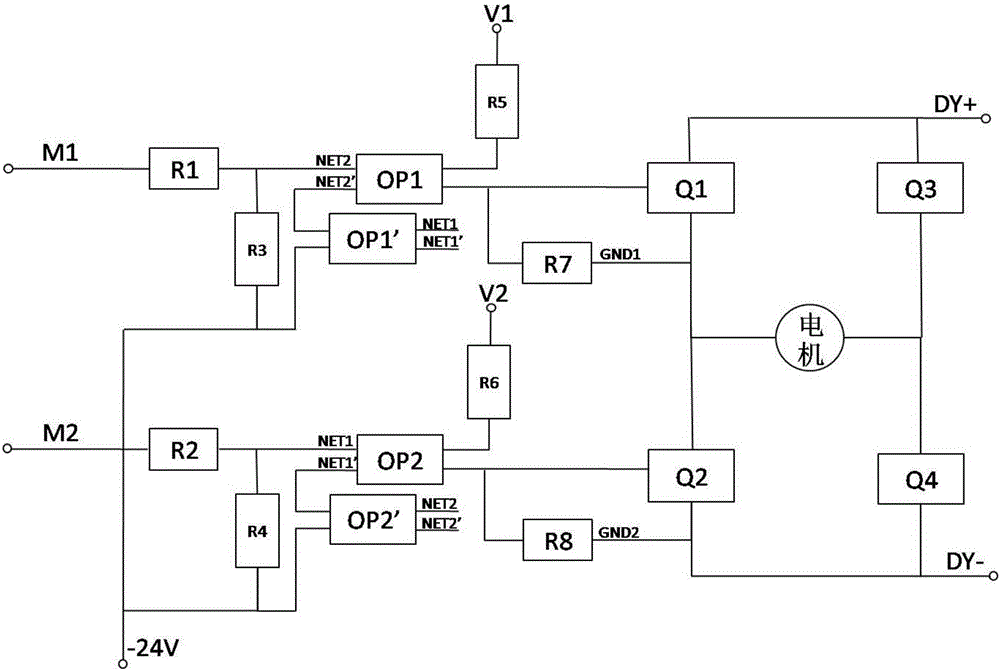

[0015] A mutually exclusive drive circuit for a motor H-bridge, which is used to provide drive signals for switching tubes of two sets of upper and lower bridge arms, and each set of upper and lower bridge arms is correspondingly provided with an upper bridge arm drive unit and a lower bridge arm drive unit The upper bridge arm drive unit includes a first isolation optocoupler, the primary side of the first isolation optocoupler is connected to the upper bridge arm control signal, and the secondary side is connected to the upper bridge arm switch tube; the lower bridge arm drive unit includes a second Two isolated optocouplers OP2, the primary side of the second isolated optocoupler is connected to the control signal of the lower bridge arm, and the secondary side is connected to the switch tube of the lower bridge arm.

[0016] The upper and lower bridge arm drive units also include a first mutual exclusion optocoupler and a second mutual exclusion optocoupler; the primary sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com