Simple pulse switching power pwm generating circuit and method

A technology of pulse switching and generating circuits, which is applied in the direction of electrical components, adjusting electrical variables, instruments, etc., can solve the problems of unfavorable development of small size of pulse switching power supply, complex peripheral circuits, high power consumption of chips, etc., and achieve high cost performance and solve chip problems. The effect of large volume and minimal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

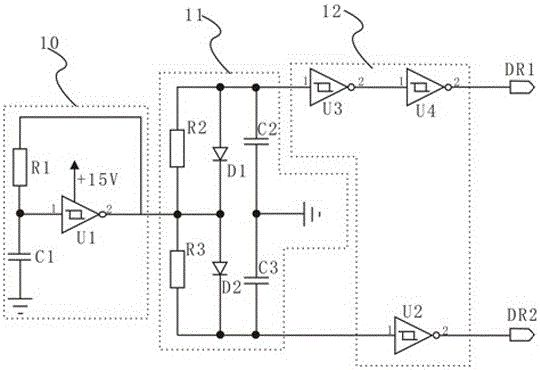

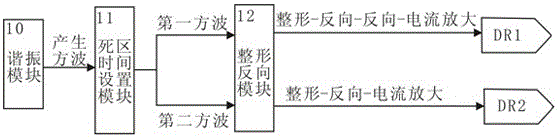

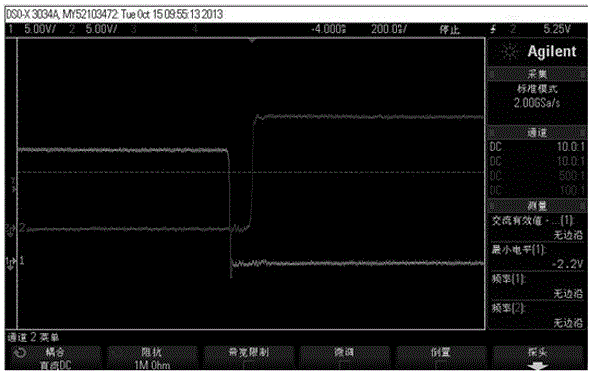

[0032] see figure 1 , the simple pulse switching power supply PWM generation circuit of the present invention includes a resonant module 10, a dead time setting module 11 and a shaping and reversing module 12; the dead time setting module 11 is electrically connected between the resonant module 10 and the reshaping and reversing module 12 , the resonant module 10 self-oscillates to generate a square wave signal, and the square wave signal passes through the dead time setting module 11 and the shaping and inversion module 12 in sequence to obtain the first PWM for corresponding to the MOS tubes of different bridge walls of the driving pulse switching power supply. The pulse signal DR1 and the second PWM pulse signal DR2 have equal duty ratios and a set dead zone.

[0033] In this embodiment, the first resistor R1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com