Positioning reference point and method for improving cutting precision of circuit board

A technology of positioning datum and positioning method, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve the problems of affecting cutting accuracy and inaccurate positioning coordinates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

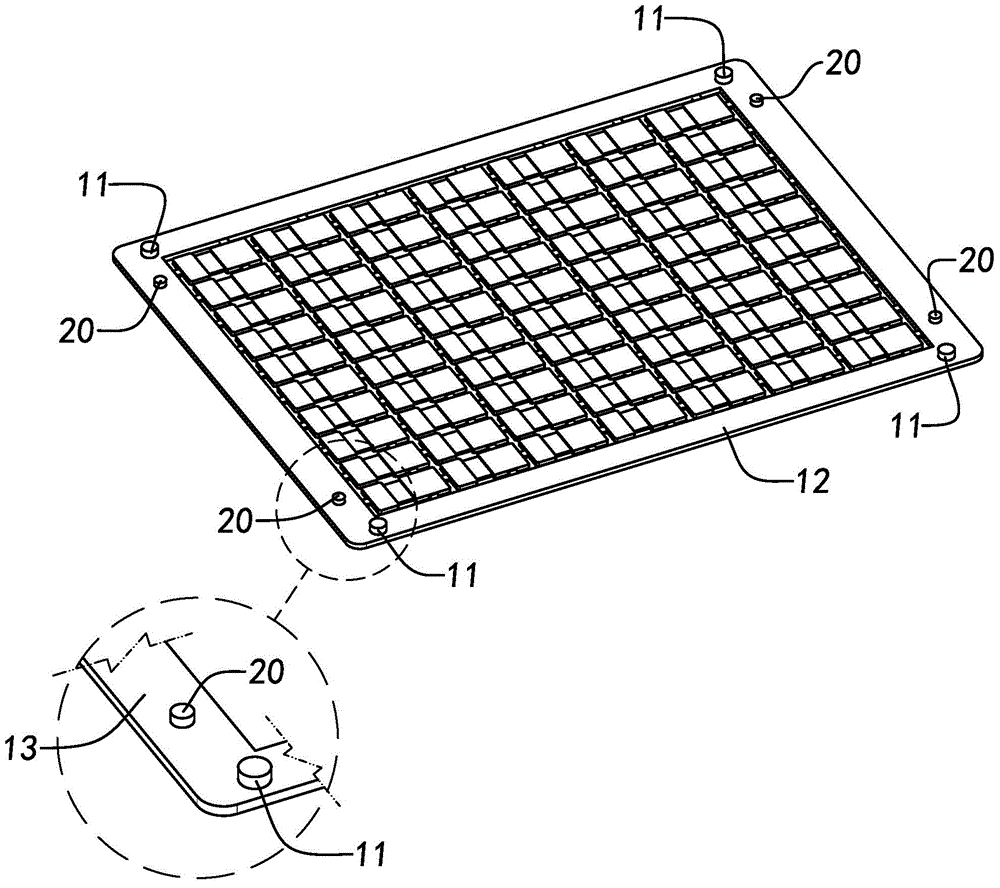

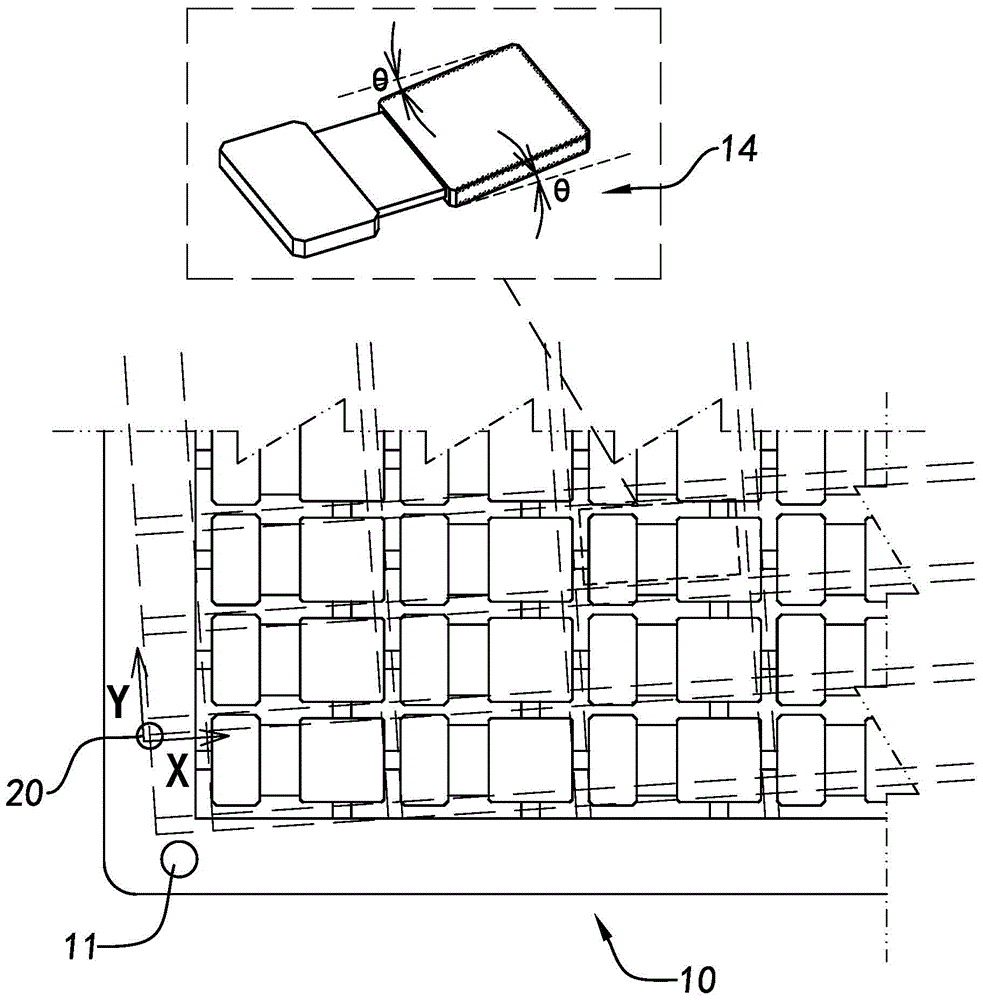

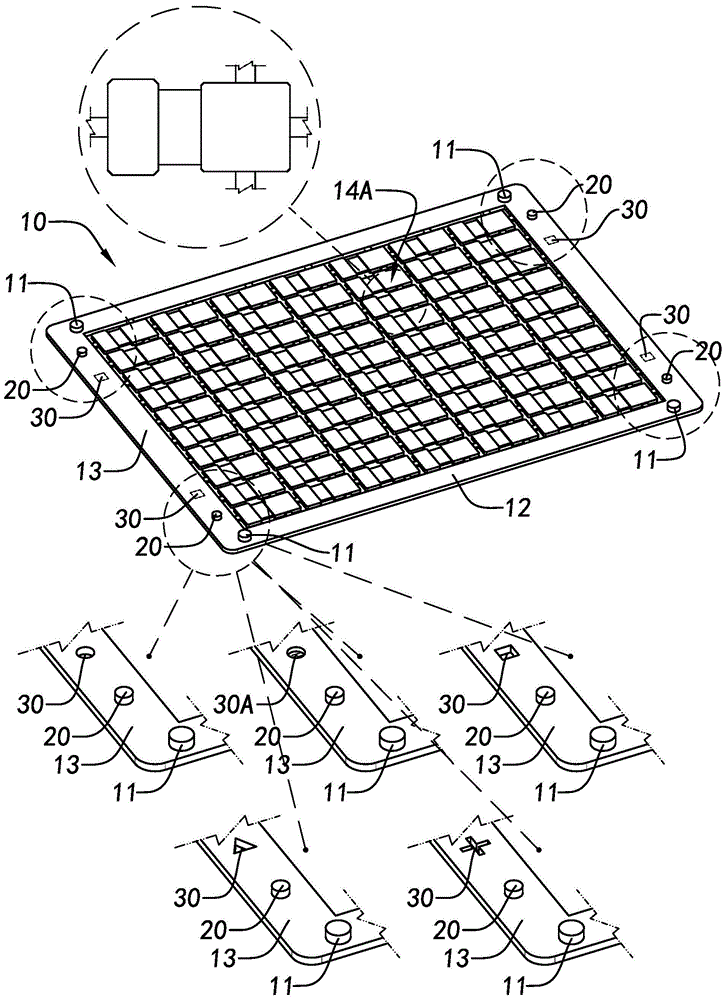

[0037] like figure 1 As shown, a printed circuit board or a printed circuit board (Printed Circuit Board, referred to as PCB) 10 has a tooling positioning piece 11 at each of the four corners, which can be a positioning column or a positioning hole, and is used for printing circuits and other operations. Positioning, wherein the tooling positioning part is set on a PCB substrate 12, preferably at the four corners, and the PCB substrate can be printed cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com