Control method of universal conversion integrated waterway module

A technology that integrates waterways and control methods. It is applied in the direction of manufacturing tools, auxiliary devices, and auxiliary welding equipment. It can solve problems that affect the accuracy of measurement and monitoring equipment, shorten equipment maintenance cycles, and reduce cooling effects. It reduces the difficulty of installation and maintenance. Reduce maintenance time and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

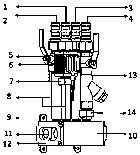

[0024] Combine below figure 1 , the present invention is further described:

[0025] Such as figure 1 As shown, universal conversion integrated fluid distribution unit: This product mainly distributes cooling water to corresponding equipment according to the different flow requirements of the equipment. The main functional components are pagoda head (spherical seal), ball valve, combined valve, flow monitor, front and rear fixing plates, left and right fastening plates, stainless steel pipes and fluid distribution blocks.

[0026] Specifically, it is a universal conversion integrated waterway module, the welding tongs water inlet head 1 and the fluid distribution block 11 are connected through the welding tongs water inlet pipe, and the total return water head 2 and the fluid distribution block 11 are connected through the total The connection of the return water pipe, the connection between the welding tongs return water pagoda head 3 and the fluid distribution block 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com