A flexible color micro-led preparation method and prepared product

A flexible and colorful technology, applied in the field of flexible color Micro-LED preparation methods and prepared products, can solve the problems of huge number of chips, color conversion, transfer, etc., achieve large transfer volume, reduce production costs, reduce the number of times of transfer and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

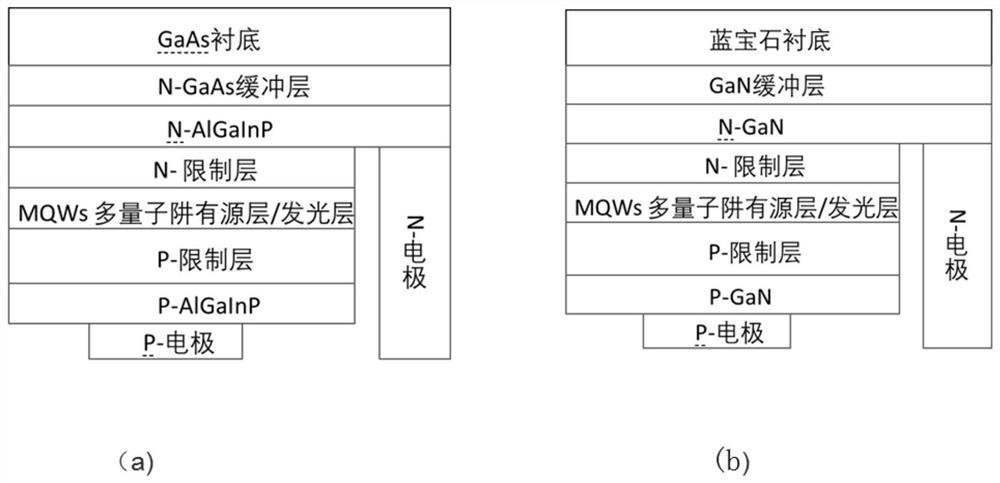

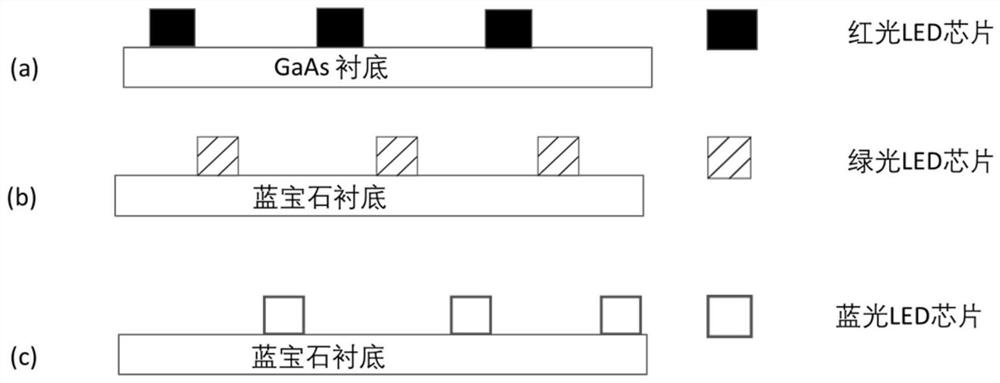

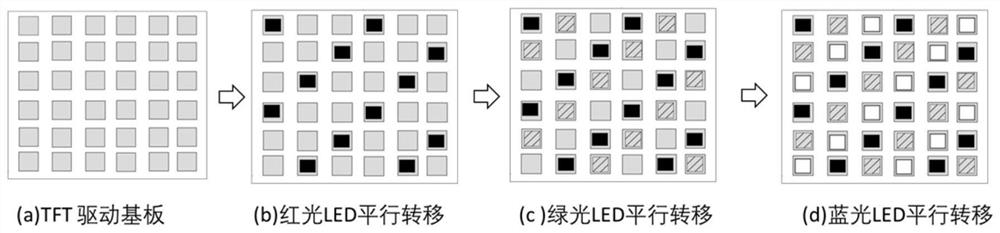

[0026] Step 1. Pre-fabrication of patterned red flip-chip microchips (pixels) on the GaAs substrate LED wafer (including epitaxial layer) by photolithography or mutual induction coupled plasma etching (ICP) (see figure 1 (a)), with a size of 8 μm. Anneal the manufactured Micro-LED chips in a vacuum furnace.

[0027] Step 2. Make patterned GaN-based green and blue flip chips (pixels) on the sapphire substrate LED wafer (including epitaxial layer) by photolithography or inductively coupled plasma etching (ICP) respectively (see figure 1 (b) and (c)), with a size of 8 μm. The green and blue chips produced were annealed in a vacuum furnace respectively.

[0028] Step 3, performing selective etching on the GaAs substrate of the red light microchip to obtain a patterned chip supported by a thin film.

[0029] Step 4, the sapphire substrates on the green light and blue light microchips are respectively lifted off by laser.

[0030] Step 5. Translating the pattern-shaped red light...

Embodiment 2

[0036] Step 1. Pre-fabrication of patterned red flip-chip microchips (pixels) on the GaAs substrate LED wafer (including epitaxial layer) by photolithography or mutual induction coupled plasma etching (ICP) (see figure 1 (a)), with a size of 7 μm. Anneal the manufactured Micro-LED chips in a vacuum furnace.

[0037] Step 2. Make patterned GaN-based green and blue flip chips (pixels) on the sapphire substrate LED wafer (including epitaxial layer) by photolithography or inductively coupled plasma etching (ICP) respectively (see figure 1 (b) and (c)), with a size of 7 μm. The green and blue chips produced were annealed in a vacuum furnace respectively.

[0038] Step 3, performing selective etching on the GaAs substrate of the red light microchip to obtain a patterned chip supported by a thin film.

[0039] Step 4, the sapphire substrates on the green light and blue light microchips are respectively peeled off by laser.

[0040] Step 5. Translating the pattern-shaped red light...

Embodiment 3

[0046] Step 1. Pre-fabrication of patterned red flip-chip microchips (pixels) on the GaAs substrate LED wafer (including epitaxial layer) by photolithography or mutual induction coupled plasma etching (ICP) (see figure 1(a)), with a size of 6 μm. Anneal the manufactured Micro-LED chips in a vacuum furnace.

[0047] Step 2. Make patterned GaN-based green and blue flip chips (pixels) on the sapphire substrate LED wafer (including epitaxial layer) by photolithography or inductively coupled plasma etching (ICP) respectively (see figure 1 (b) and (c)), with a size of 6 μm. The green and blue chips produced were annealed in a vacuum furnace respectively.

[0048] Step 3, performing selective etching on the GaAs substrate of the red light microchip to obtain a patterned chip supported by a thin film.

[0049] Step 4, the sapphire substrates on the green light and blue light microchips are respectively lifted off by laser.

[0050] Step 5. Translating the pattern-shaped red light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com