An oblique cone guide pin type one-section drum left and right turn-up capsule drum mechanism

A technology of flipping drums and capsules, applied in tires, household appliances, other household appliances, etc., can solve the problem of sagging of the rubber adhesive layer, and achieve the effect of improving the effect, reducing the defective rate of tire production and prolonging the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

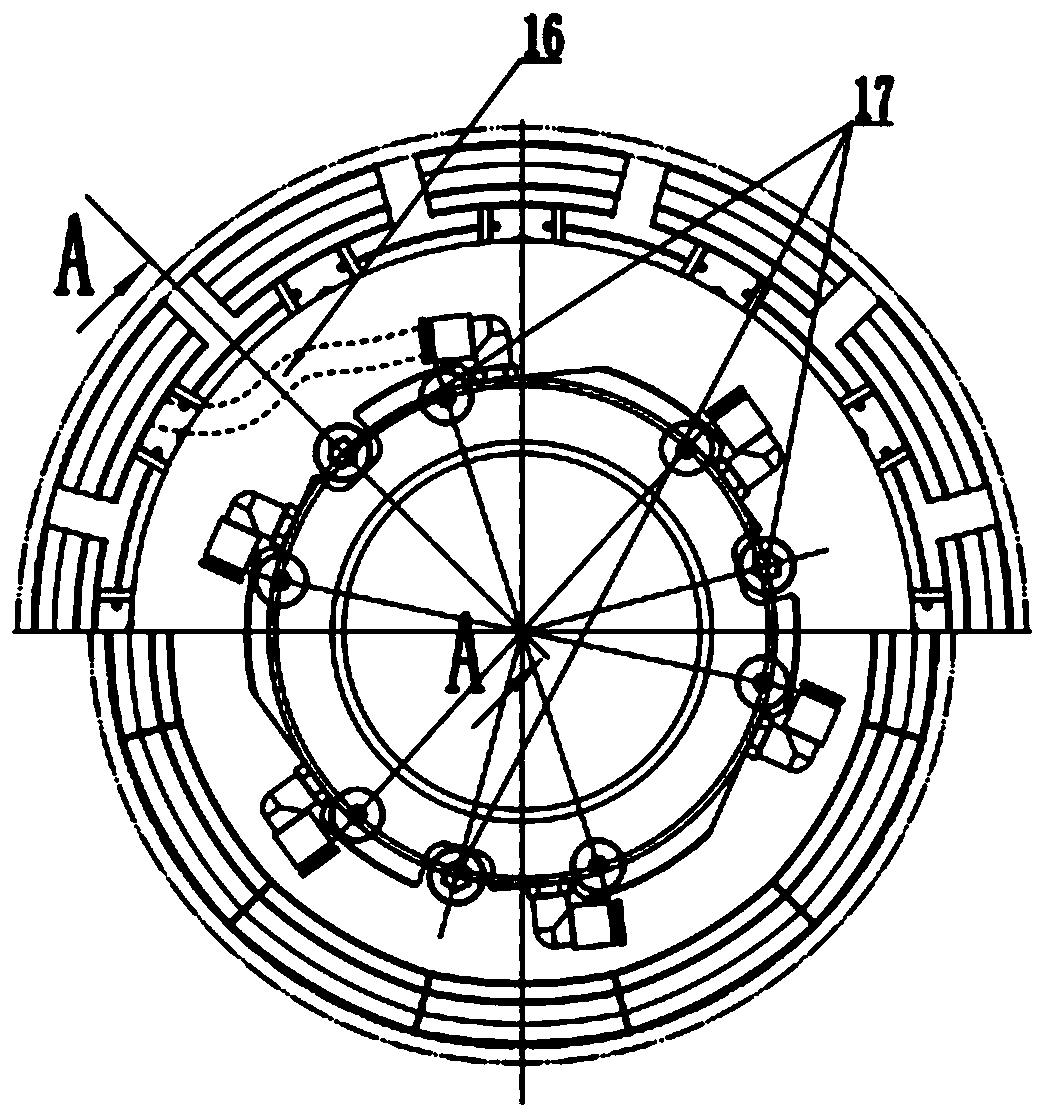

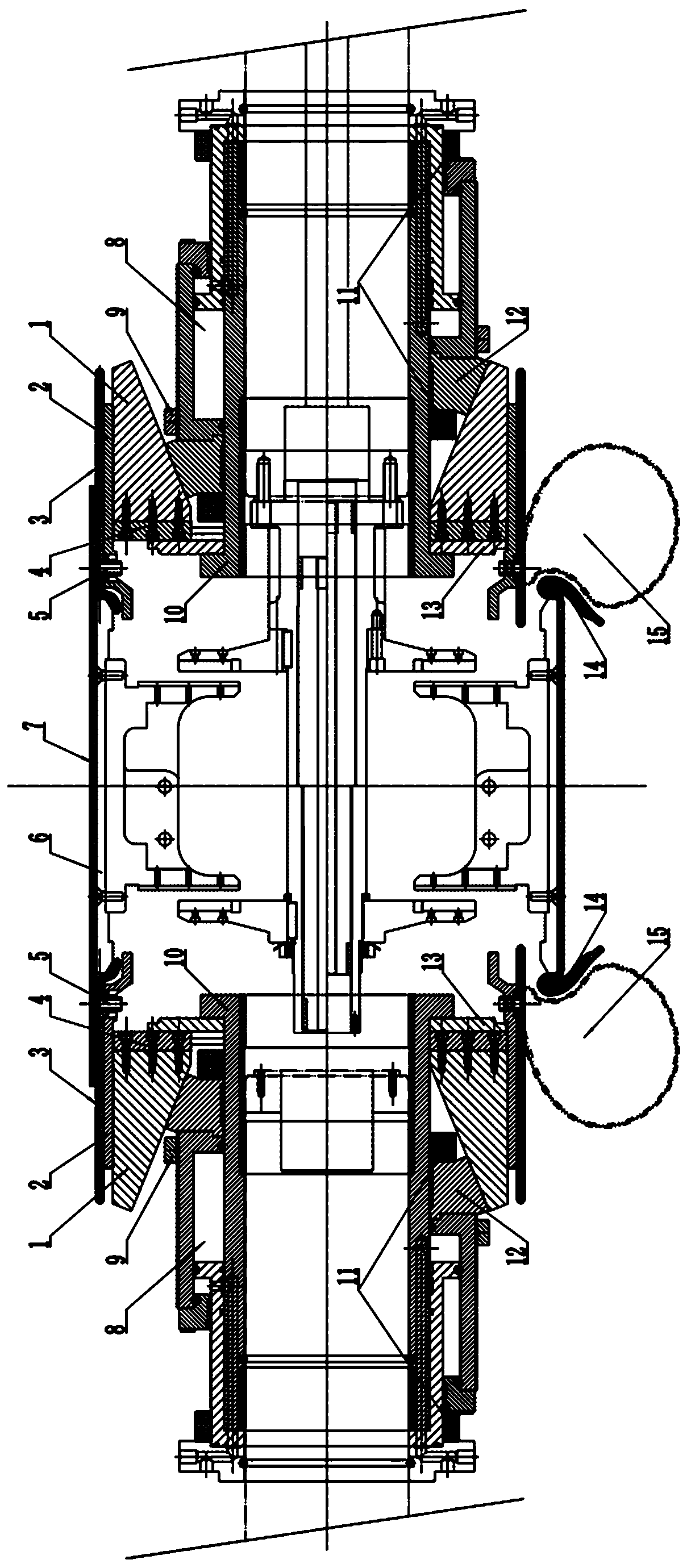

[0022] like Figure 1-2 As shown in the figure, a slanted cone guide pin type one-stage drum mechanism for wrapping capsules on the left and right sides includes a horizontally placed main shaft, a forming drum plate 6 arranged on the surface of the middle section of the main shaft, and two symmetrically turned-up side drums at the left and right ends of the main shaft. , the turn-up side drum includes a plurality of turn-up drum plates 2, turn-up capsules 3, turn-up drum board radial expansion and contraction motion devices uniformly distributed on the circumference of the main shaft surface, and the turn-up drum board 2 radially expands In the open state, the outer diameter is the same as the expanded outer diameter of the forming drum plate 6, so that the two are connected in a straight line; the radial expansion and contraction movement device of the turn-up drum plate 2 is composed of the cylinder 8, the drive plate 12, and the turn-up drum support cylinder. 10. The guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com