Natural solidifying equipment for synchronous cutting of coated paperboards

A curing equipment and cardboard technology, applied in the direction of mechanical processing/deformation, can solve the problems of large pollution, high energy consumption, poor cutting effect, etc., and achieve the effect of reducing production cost, improving production efficiency, and good strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

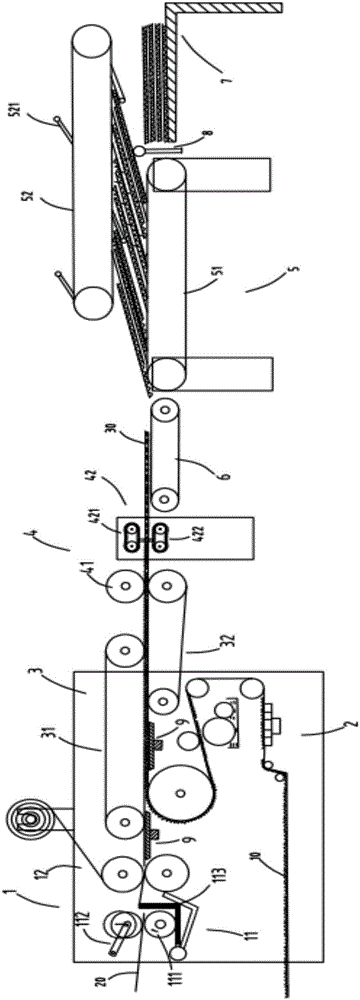

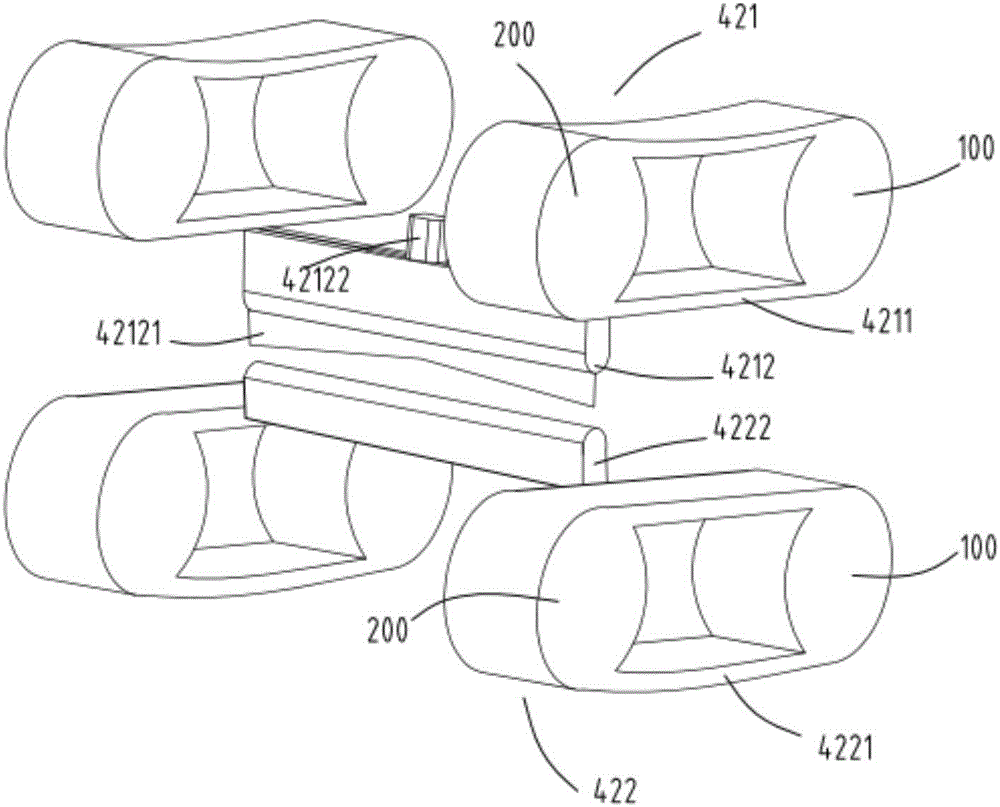

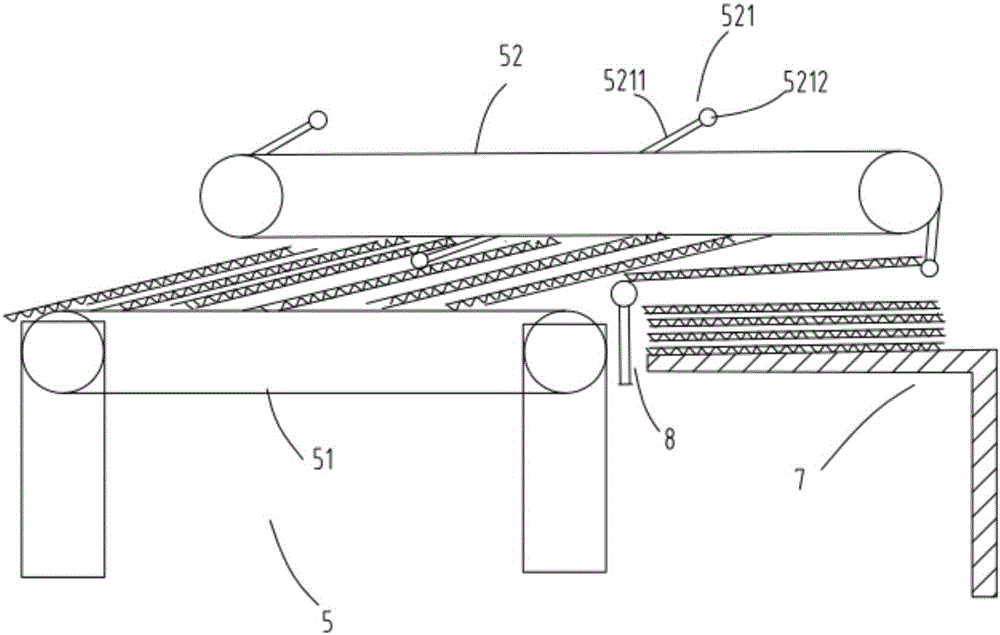

[0029] figure 1 Schematic diagram of synchronous cutting and natural curing equipment for laminated paperboard, figure 2 A schematic diagram of a synchronous cross-cutting machine, image 3 Schematic diagram of the layered conveying curing section, Figure 4 Schematic diagram of positioning the laminating part for the face paper, Figure 5 A schematic diagram of the corrugated paper processing section. Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5As shown, what is provided in this embodiment is a kind of synchronous cutting and natural curing equipment for laminated cardboard, the face paper positioning laminating part 1, corrugated paper processing part 2, pressing part 3, cutting part 4 and stacking and curing conveying part 5 ; The facial tissue positioning laminating part 1 is arranged at the front end of the pressing part 3; the corrugated paper processing part 2 is arranged at the lower end of the pressing part 3; the cutting part 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com