Overhanging part of non-removable formwork system

A technology that does not need to dismantle formwork and pick parts, which is applied to building components, building reinforcements, structural elements, etc., can solve the problems of storage, maintenance, transportation, hoisting, inconvenient installation, waste of resources, hidden dangers, etc., to facilitate later transportation. , The effect of reducing self-weight and effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present application will be described in detail below with reference to the drawings and examples.

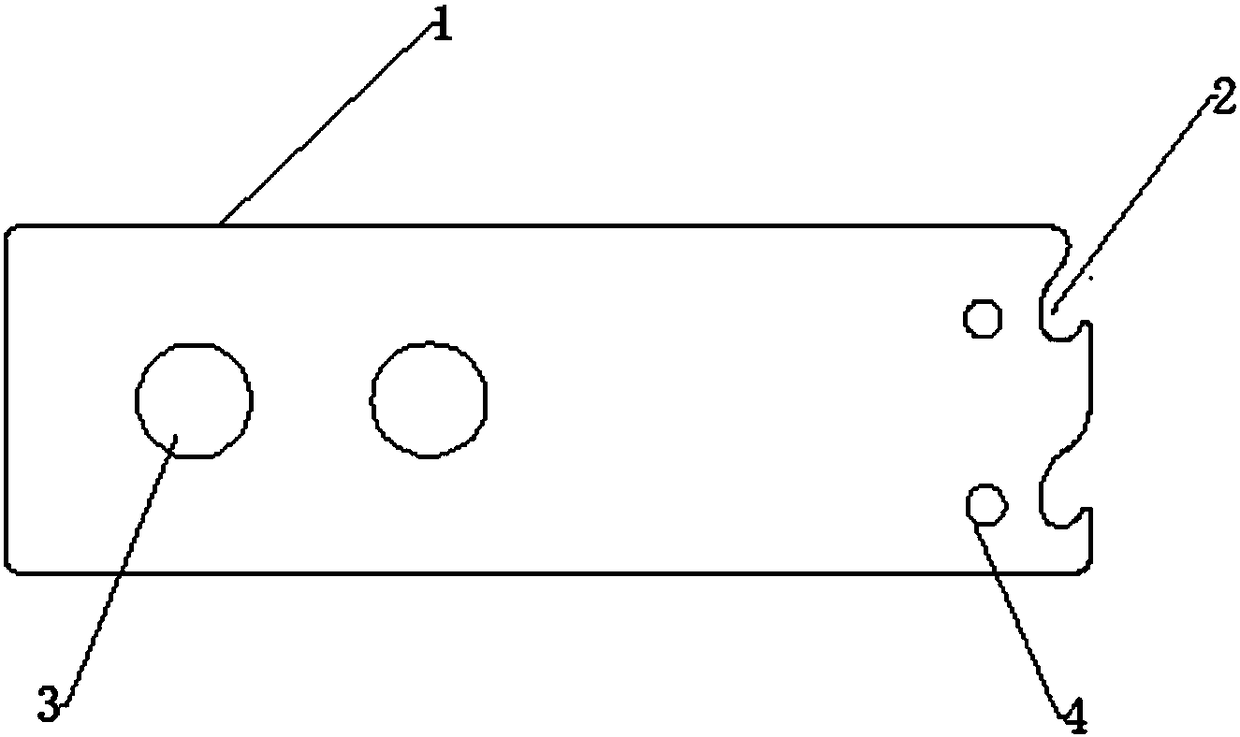

[0017] Such as figure 1 As shown, the present invention provides a pick-up part of the formwork system without dismantling, which is a plate-shaped body, and one end of the plate-shaped body is provided with a hook; the end of the plate-shaped body far away from the pick-up hook is provided with a hanging point hole The mechanism makes the structure simpler and reduces the weight of the component itself; a connection hole is provided near the pick hook, which can be more effectively connected with the internal support system.

[0018] Further, the end of the plate-shaped body is provided with an inwardly recessed hook groove to form the lifting hook. The pick hooks are connected to the external support points to effectively fix the reinforcement mesh of the protective surface layer and ensure the thickness of the concrete protective layer of the reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com