Special device for gluing seamless wall cloth

A special device, the technology of seamless wall covering, applied in decorative arts, pasting and other directions, can solve the problems of baking the wall covering, sticking the wall covering not firmly, not sticking the wall covering firmly, etc., and achieving good overall effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

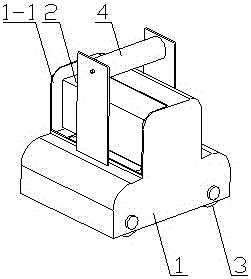

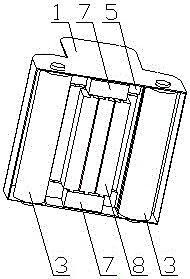

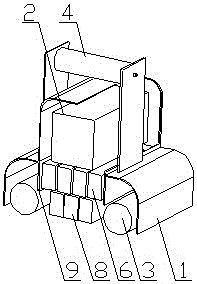

[0012] Such as Figure 1-4 As shown, the present invention includes: a housing 1, a hot air blower 2, a pair of silicon rubber rollers 3, a handle 4, a pair of first mounts 5, a set of first heating sheets 6, a pair of second mounts 7, A group of second heating sheets 8 and a pair of deflectors 9, the housing 1 is divided into an upper part and a lower part, an opening 1-1 is provided on one side of the upper part, and a steel mesh is installed at the opening 1-1, and the hot air blower 2 Installed on the upper part of the housing 1, the two ends of the pair of silicon rubber rollers 3 are respectively installed on the lower part of the housing 1 through the bearing seat, and the two ends of the handle 4 are installed on the housing 1 through the connecting plate. A mounting seat 5 is respectively installed on the inner wall of the lower part of the housing 1, and the two ends of a group of first heating plates 6 are respectively installed on a pair of first mounting seats 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com