Swing piece conveying support

A technology for ornaments and adjustment racks, which is applied in the field of automation equipment, can solve the problems such as the inability to adjust the conveying angle, and achieve the effects of simple structure, meeting distance requirements, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

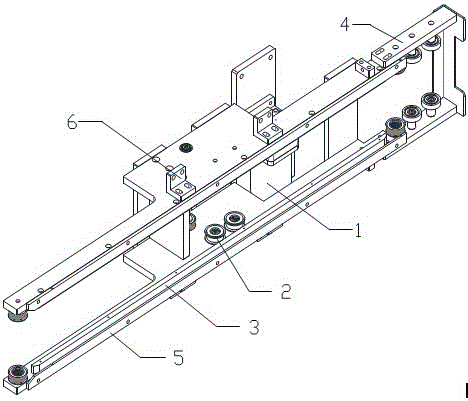

[0014] Ornament conveying bracket, including bracket body 1, roller 2, support plate 3, adjustment frame 4, guard plate 5, installation plate 6, is characterized in that the bracket body 1 is composed of two parallel symmetrical side plates and a gap between the two side plates The connecting part consists of a plurality of mounting plates 6 arranged on the outside of the bracket body 1, the bracket body 1 is connected with the adjustment frame 4, and there are multiple rollers 2, and the plurality of rollers 2 are respectively arranged on the bracket body 1 and the adjustment frame 4, and the bracket body A guard plate 5 is installed on the side plate of 1, and a support plate 3 is arranged below the guard plate 5. The side plate of the bracket body 1 is T-shaped. The rollers 2 are arranged at least at both ends of the support body 1 , at both ends of the adjustment frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com