lubricating oil for gears

A lubricating oil and gear technology, applied in the field of lubricating oil, can solve the problems of not fully satisfying the use requirements, short service life, high preparation cost, and achieve the effects of excellent self-repairing function, high flash point and long oil change interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

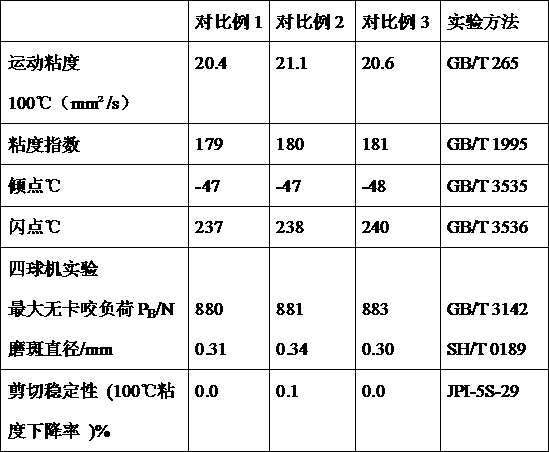

Image

Examples

Embodiment 1

[0022] A lubricating oil for gears, made of the following components in parts by weight, modified base oil 115, succinate 1, diethylenetriaminepentamethylene phosphonic acid 2, octyl diphenylamine 1, sorbitol 5, Nano-copper powder 0.1, dodecanedibasic acid 1, β-sitosterol 0.4, cholesterol nonanoate 1, coconut acid glycol amide 0.2, auxiliary additive 6;

[0023] The modified base oil is made of the following components in parts by weight: polyalphaolefin 100, urea 0.3, rare earth carbonate 0.001, phosphate ester 0.4, soybean oil 1, hydrogen peroxide 0.1, methoxypolyethylene glycol methacrylic acid ester 0.5; the particle size of the rare earth carbonate is 0.1 μm; the kinematic viscosity of the poly-α-olefin at 100°C is 8-60 mm² / s; the preparation method of the modified base oil is: 1. α-Olefin and soybean oil are mixed and added to the reactor, heated to 178°C, and kept for 40 minutes; ②Add urea and phosphate ester to the reactor in ①, heated to 188°C, and stirred at 150r / min...

Embodiment 2

[0029] A kind of lubricating oil for gears, made of the following components in parts by weight, modified base oil 118, succinate 3, diethylenetriaminepentamethylene phosphonic acid 4, octyl diphenylamine 2, sorbitol 7, Nano copper powder 0.2, dodecanedibasic acid 2, β-sitosterol 0.6, cholesteryl nonanoate 3, coconut acid glycol amide 0.5, auxiliary additive 8;

[0030] The modified base oil is made of the following components in parts by weight: polyalphaolefin 100, urea 0.3, rare earth carbonate 0.001, phosphate ester 0.4, soybean oil 1, hydrogen peroxide 0.1, methoxypolyethylene glycol methacrylic acid ester 0.5; the particle size of the rare earth carbonate is 0.1 μm; the kinematic viscosity of the poly-α-olefin at 100°C is 8-60 mm² / s; the preparation method of the modified base oil is: 1. α-Olefin and soybean oil are mixed and added to the reactor, heated to 178°C, and kept for 40 minutes; ②Add urea and phosphate ester to the reactor in ①, heated to 188°C, and stirred at ...

Embodiment 3

[0036] A lubricating oil for gears, made of the following components in parts by weight, modified base oil 116, succinate 2, diethylenetriaminepentamethylene phosphonic acid 2, octyl diphenylamine 1, sorbitol 7, Nano copper powder 0.1, dodecanedibasic acid 2, β-sitosterol 0.4, cholesteryl nonanoate 1, coconut acid glycol amide 0.3, auxiliary additive 7;

[0037] The modified base oil is made of the following components in parts by weight: polyalphaolefin 100, urea 0.3, rare earth carbonate 0.001, phosphate ester 0.4, soybean oil 1, hydrogen peroxide 0.1, methoxypolyethylene glycol methacrylic acid ester 0.5; the particle size of the rare earth carbonate is 0.1 μm; the kinematic viscosity of the poly-α-olefin at 100°C is 8-60 mm² / s; the preparation method of the modified base oil is: 1. α-Olefin and soybean oil are mixed and added to the reactor, heated to 178°C, and kept for 40 minutes; ②Add urea and phosphate ester to the reactor in ①, heated to 188°C, and stirred at 150r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com