Foundation pit supporting method for ground tube pile anchor frame

A foundation pit support and frame technology, which is applied in excavation, foundation structure engineering, construction, etc., can solve the problems of limited anti-overturning capacity of double-row piles, inability to construct anchor cables, and large deflection of steel supports, so as to shorten the construction period and reduce the The effect of high cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

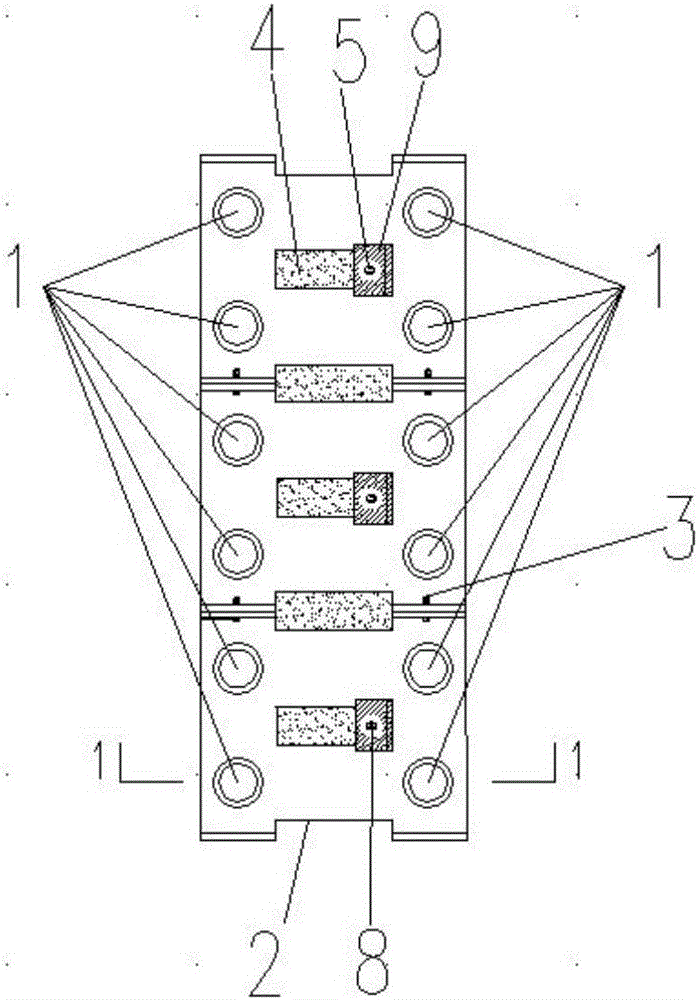

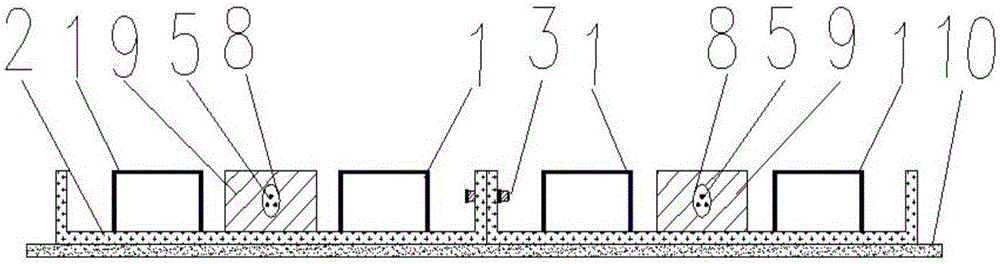

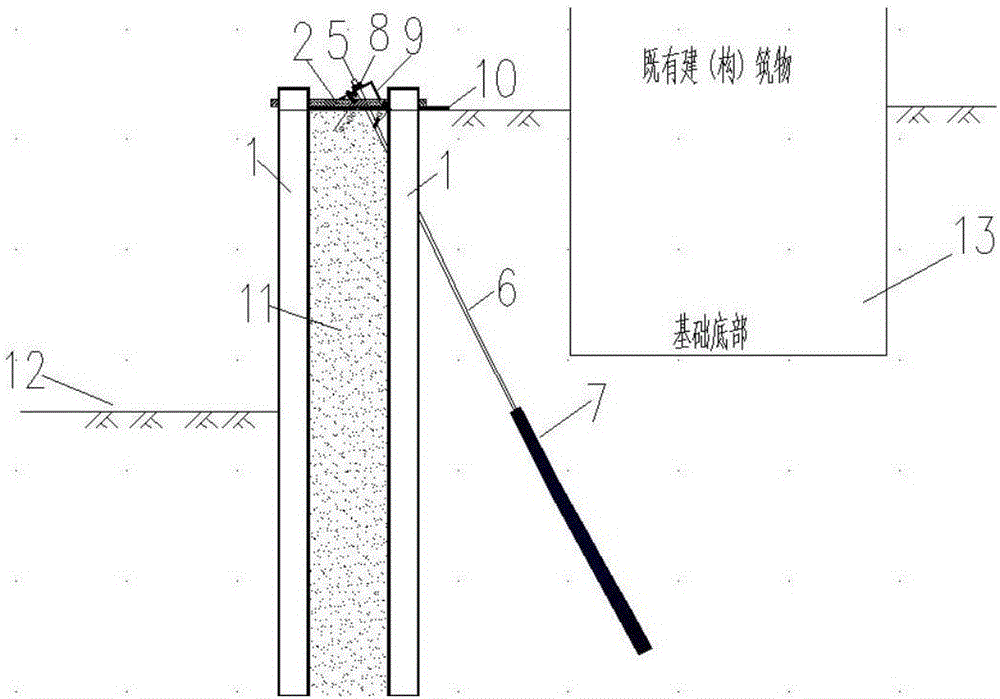

[0022] The following is attached Figure 1-4 The present invention is described in further detail.

[0023] A ground pipe pile anchor frame foundation pit support method, the implementation process of the method is as follows, first, the prefabricated assembled frame composite beam (2), laying pile holes in the assembled frame composite beam (2), the size of the pile holes Calculated according to design specifications. Secondly, the prefabricated frame composite beam (2) is poured on the leveled construction site by using a low-strength concrete cushion. A static pressure construction method is adopted to press concrete pipe piles (1) with a diameter of 400 mm to 600 mm into the formation in the reserved holes of the assembled frame composite beam (2). The prestressed anchor cable (5) is laid in the reserved square hole (4) between the front and rear rows of piles, the anchor cable passes through the reserved anchor cable hole of the anchor cable reaction seat (9) and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com