Film-coated heat-insulation sound absorption wool

A sound-absorbing cotton and coating technology, applied in the field of building materials, can solve the problems of weakening the heat-insulating and sound-absorbing effect of glass wool, glass wool easily absorbing water vapor, and dust-absorbing glass wool, etc., so as to achieve low production cost, good promotion prospects, and convenient product processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

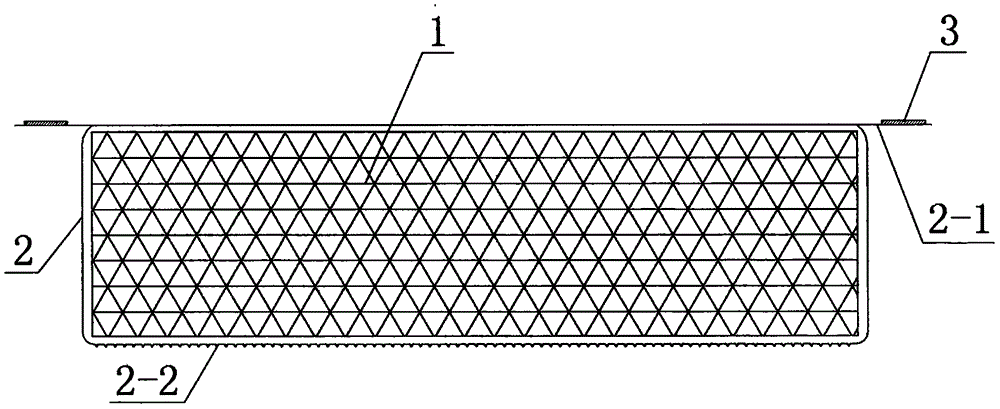

[0011] A kind of coated heat-insulating and sound-absorbing cotton, such as figure 1 As shown, it includes a glass wool 1 and a film cover 2, the glass wool 1 is flatly packaged in the film cover 2, and both sides of the film cover 2 are formed with a bonding part 2-1, and the bonding part 2-1 One side of the surface is coated with viscose 3, and the viscose 3 is covered with release paper, and densely packed micro-sound-absorbing holes 2-2 are evenly formed on one or both sides of the film cover 2, and the micro-sound-absorbing holes 2-2 are tapered And protrude to the outside of the film cover 2. On the one hand, the glass wool 1 is flatly packaged in the film cover 2 , and at the same time, it is glued to the inner wall of the film cover 2 for positioning.

[0012] The construction and installation process of the film-coated heat-insulating and sound-absorbing cotton is very simple: just peel off the release paper on the adhesive parts 2-1 on both sides of the film cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com