Reversing-defrosting air source heat pump unit and reversing defrosting method

An air source heat pump and reversing defrosting technology, which is applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve the problems of four-way reversing valve large airflow noise, no hot air, low surface temperature, etc., to improve Comfort and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

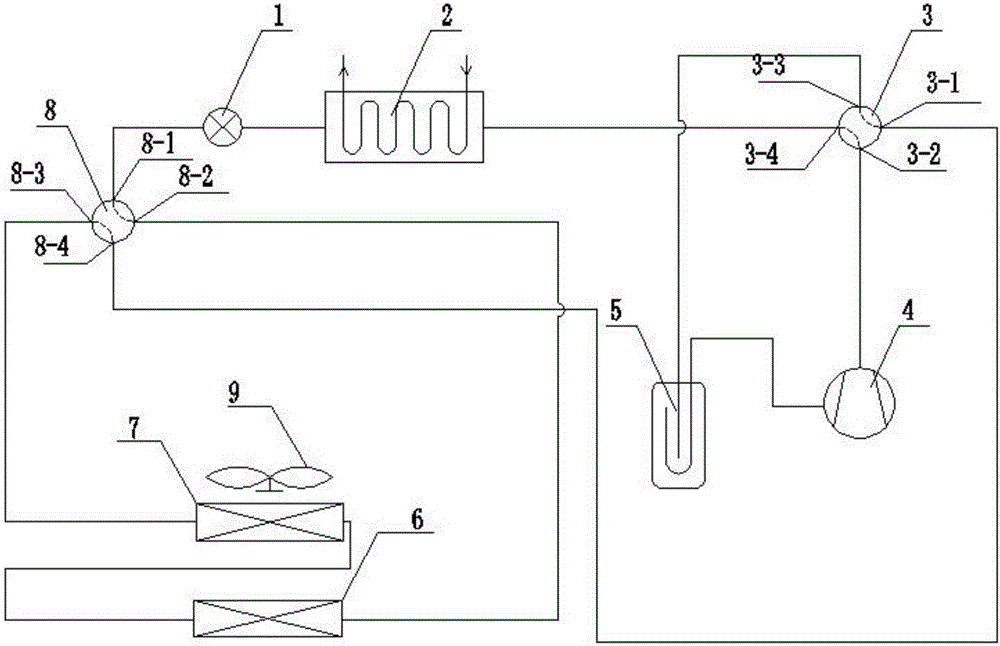

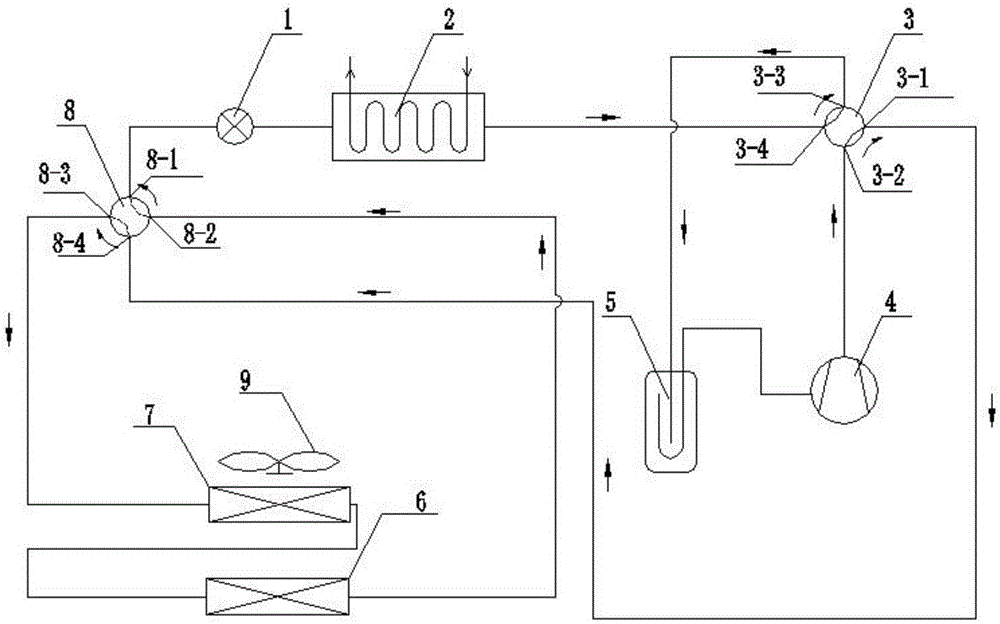

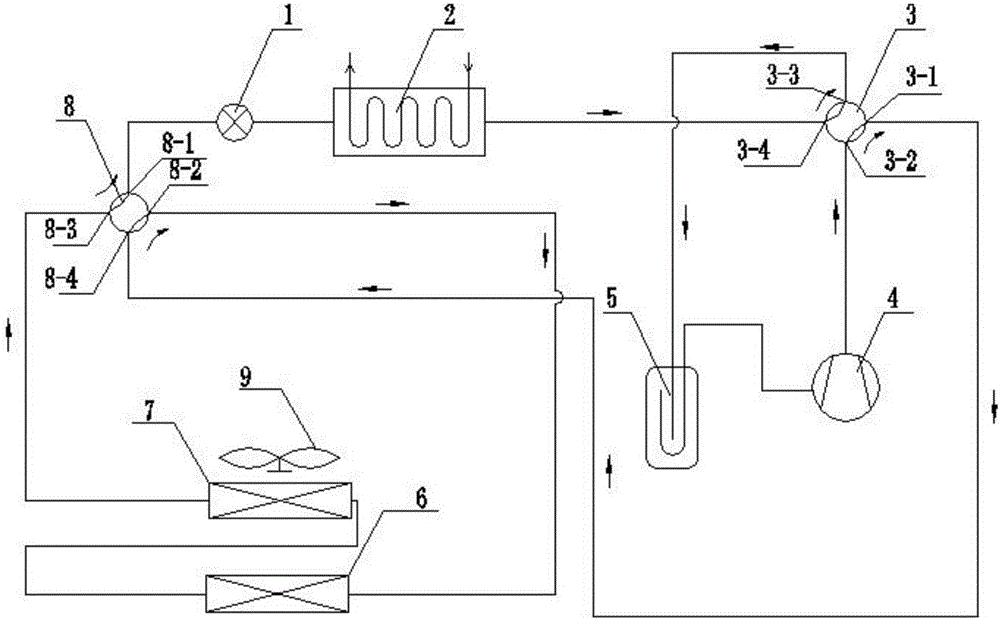

[0015] like figure 1 As shown, the reversing defrosting air source heat pump unit of the present invention is suitable for occasions where the air source heat pump is prone to frost during heating in winter, and includes a compressor 4 for compressing low-temperature and low-pressure refrigerant vapor into high-temperature and high-pressure refrigerant vapor. Outdoor side heat exchanger, fan 9 for passing outdoor air through the outdoor side heat exchanger, indoor side heat exchanger 2 for condensing and releasing heat of high-temperature and high-pressure refrigerant vapor, and gas-liquid separator for separating refrigerant vapor from liquid 5. The first four-way reversing valve for changing the refrigerant flow direction 3. The throttling mechanism 1 for throttling the high-temperature and high-pressure refrigerant liquid into low-temperature and low-pressure refrigerant liquid, wherein the outdoor heat exchanger is used for low-temperature and low-pressure refrigerant liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com