A real vehicle simulation vibration test bench for transmission shafts of different specifications

A vibration test bench, real vehicle simulation technology, applied in machine gear/transmission mechanism testing, mechanical component testing, machine/structural component testing, etc. Insufficient consideration of performance, lack of overload protection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

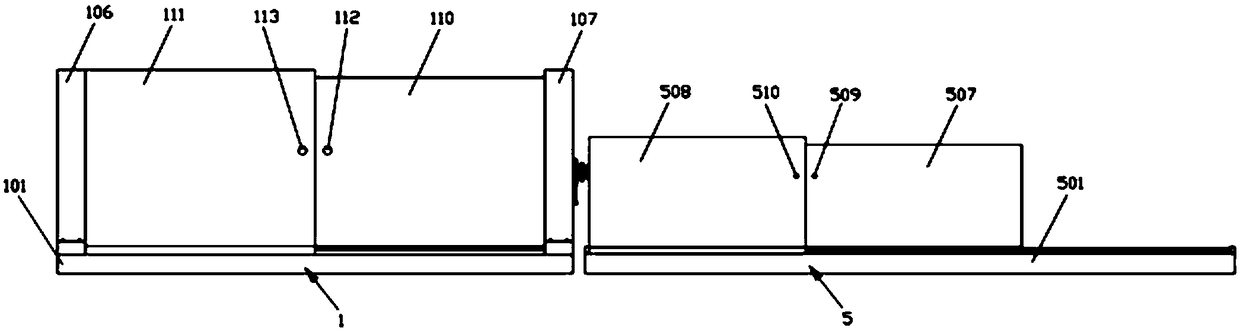

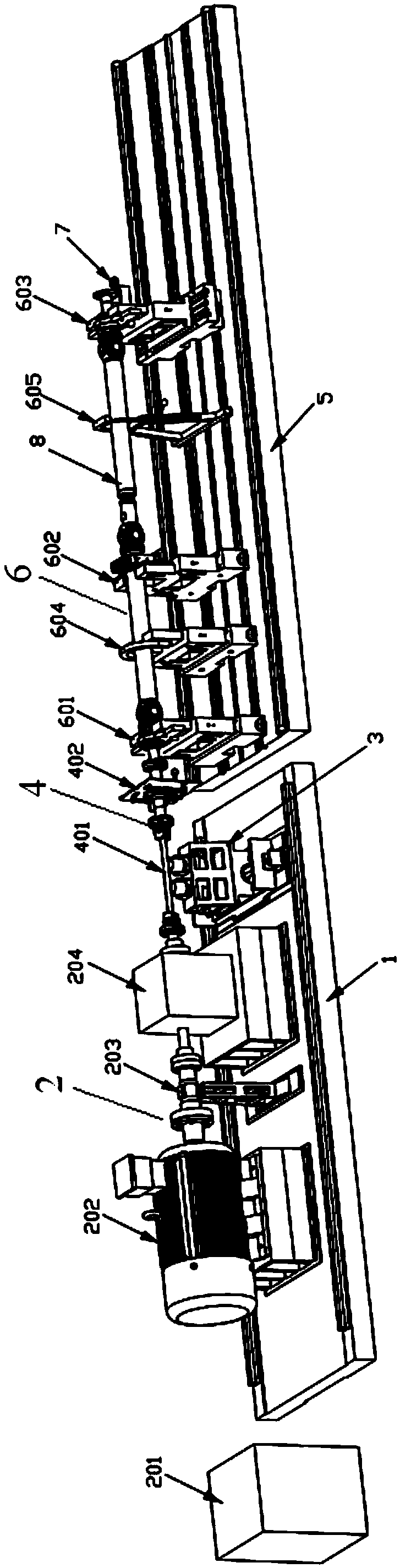

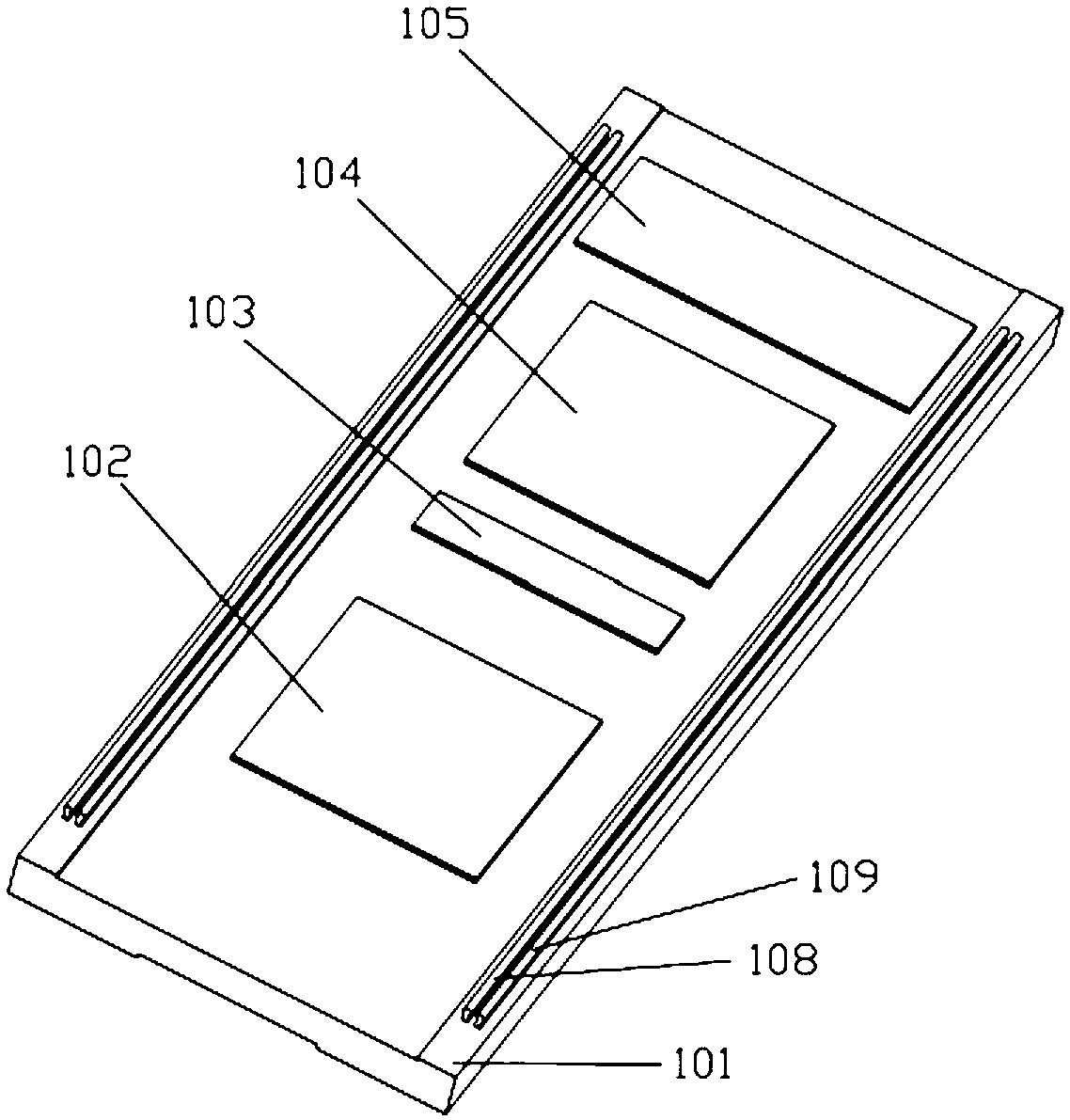

[0063] Test scheme 1: For trucks where the transmission output shaft and the main reducer input shaft are far away, the transmission shaft is often divided into two sections and an intermediate support is added for power transmission. The vibration test bench of the present invention can measure this kind of Two-stage transmission shaft assembly, and corresponding simulation tests can be made according to different model parameters and road conditions, and the equivalent angle of the transmission shaft can be quickly adjusted.

[0064] The specific test process of test scheme 1 includes: preliminary preparation work, installation process of drive shaft assembly 8, technical solution to adapt to large-scale drive shaft assembly 8, process of changing the equivalent angle of drive shaft 804, vibration test process, test bench rapid The braking process and the end of the test work.

[0065] Preliminary preparations for test plan 1:

[0066] Select the transmission shaft assembly...

test approach 2

[0080] Test plan 2: There are more short-wheelbase cars like cars on the market, and a single-segment drive shaft is often arranged for power transmission. Therefore, in order to detect such a drive shaft, the present invention provides a test plan for measuring a single-segment drive shaft. It can also measure the vibration of the transmission shaft at different speeds, different gears, different equivalent angles, and different working conditions.

[0081] The specific test process of the second test plan is as follows: the single-stage drive shaft assembly selected in this test plan is equivalent to the two-stage drive shaft assembly 8, which only retains the second universal joint 803, the drive shaft 804 and the third universal joint 805. In the second test plan, except that the installation form of the drive shaft 804 on the test bench is different from the test plan one, the preparatory work, the process of changing the equivalent angle of the drive shaft 804, the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com