A composite functional acoustic test piece

An acoustic test and composite function technology, applied in the field of acoustic test pieces, can solve the problems of lack of test pieces, long production cycle, high cost, etc., and achieve the effects of being beneficial to project realization, saving production cycle and cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

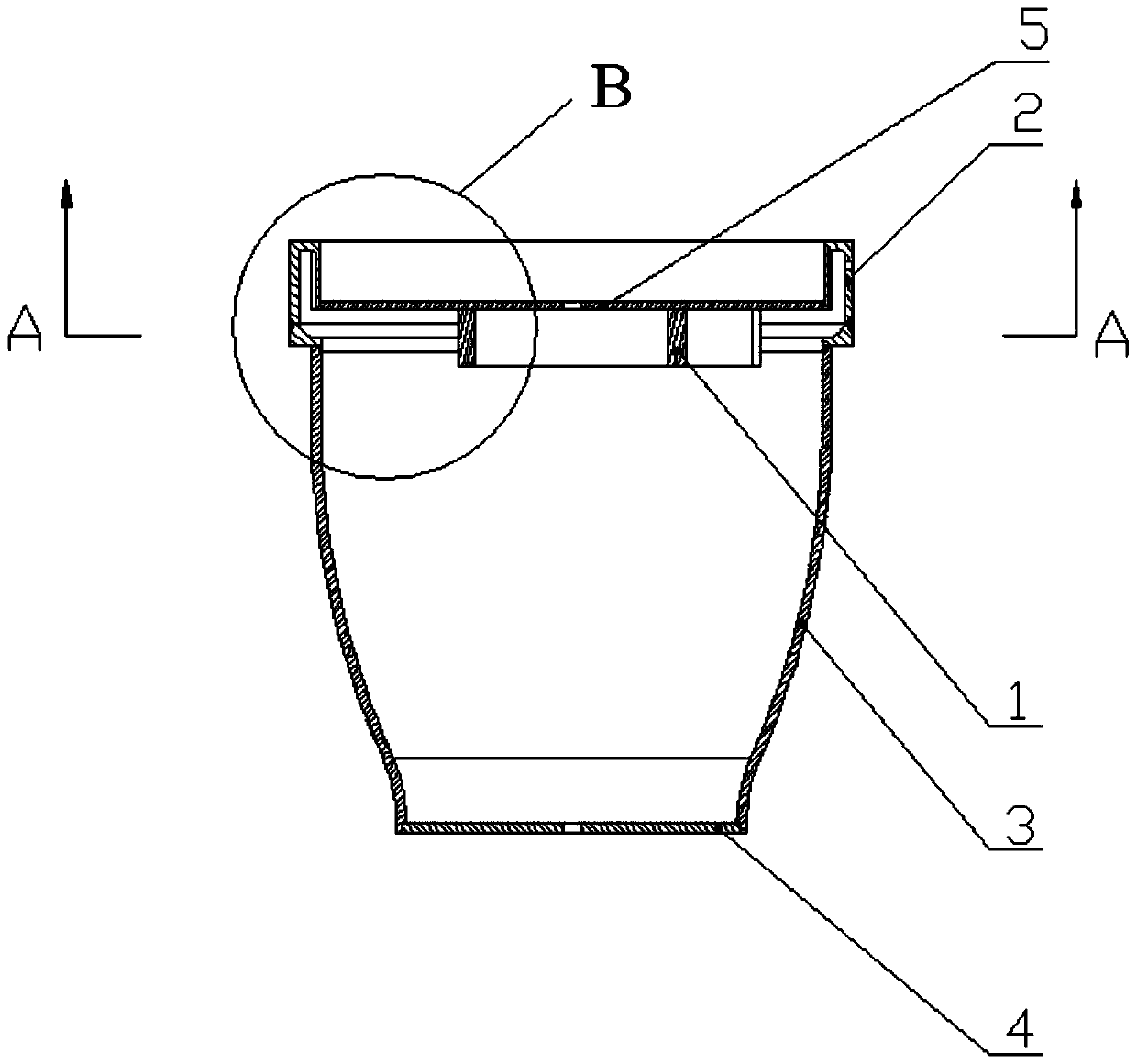

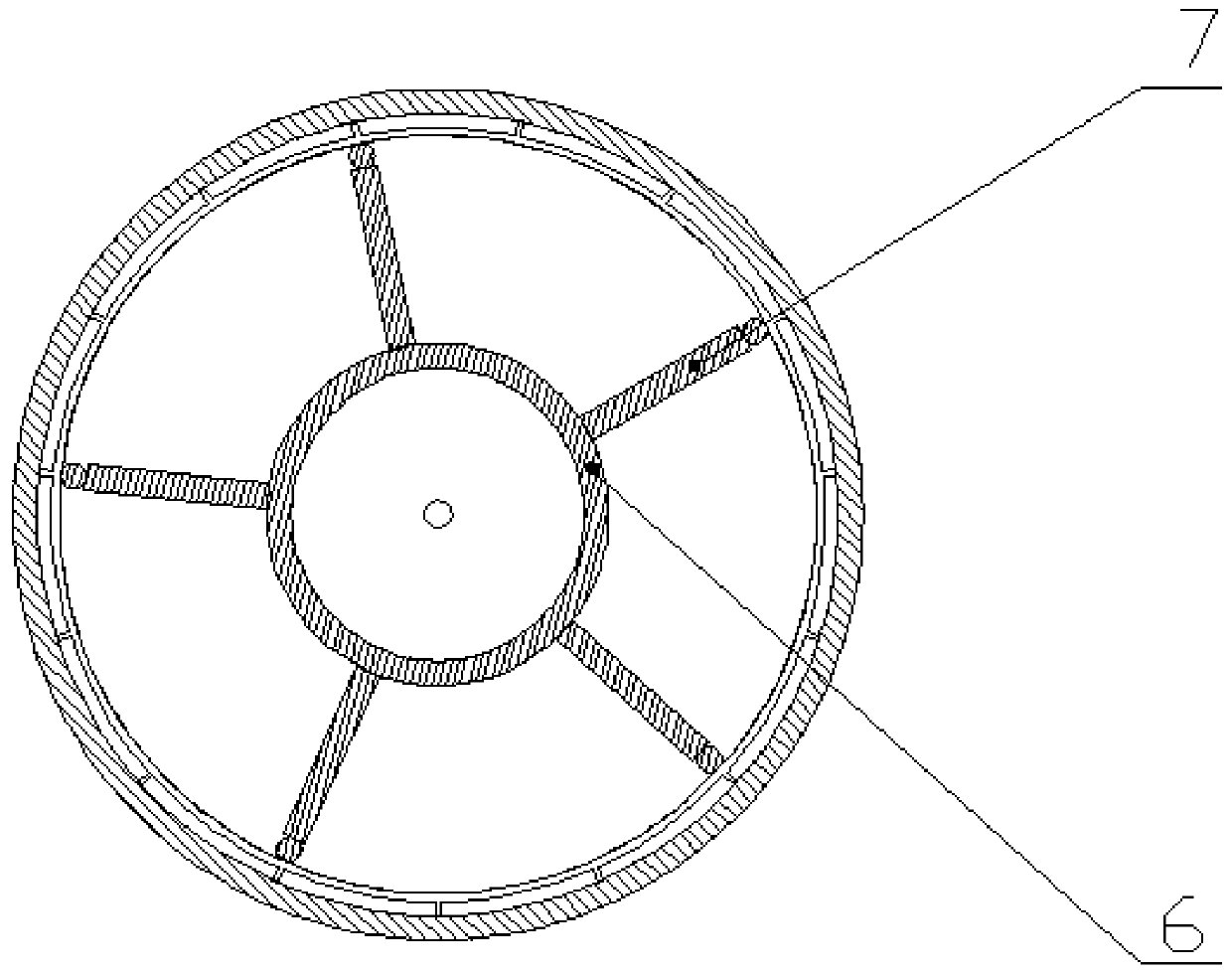

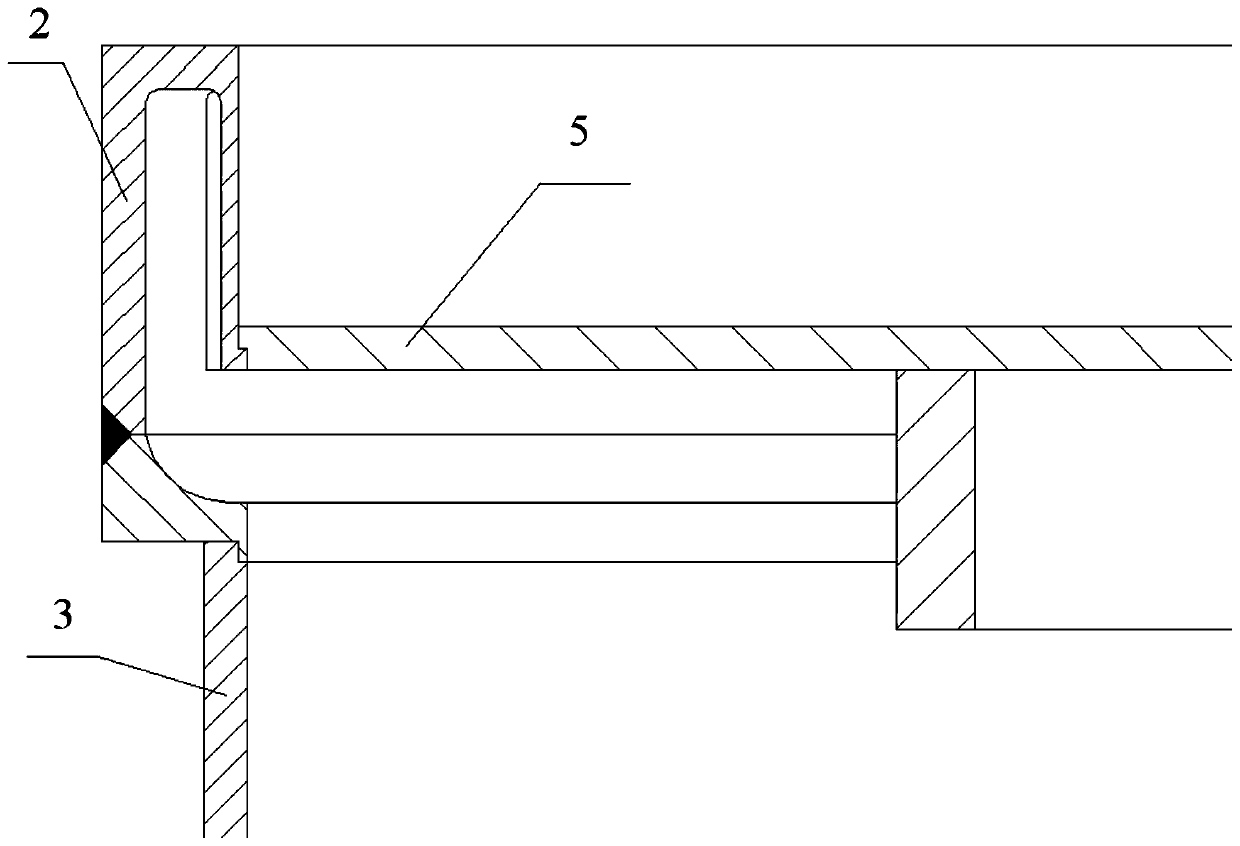

[0017] Such as figure 1 , figure 2 , image 3 As shown, a composite functional acoustic test piece includes: a partition 1, an acoustic cavity ring 2, a body section 3 and a cover 4; the body section 3 includes a straight cylinder section and a convergent section, the cylindrical section is connected with the 3 simulated the cylindrical section and the converging section of the combustion chamber. The converging section is formed by the circular arc of the inlet and the upstream arc of the throat; It is closed so that a cavity is formed inside the annular structure, and the outer cylinder is an annular flanging closing structure with the sealing end welded to the inside, which is connected with the straight barrel section of the body section 3 through the closing structure; the partition 1 includes a bottom plate 5 and a circumferential partition 6 , radial partition 7; the circumferential partition 6 is cylindrical, one end is fixed on the middle part of the bottom plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com