BIM-based steel structure net rack hydraulic lifting time-varying finite element analysis method

A hydraulic lifting, finite element technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to timely assess the stress state of steel structure grids, poor timeliness, and impact on the preparation of on-site emergency measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

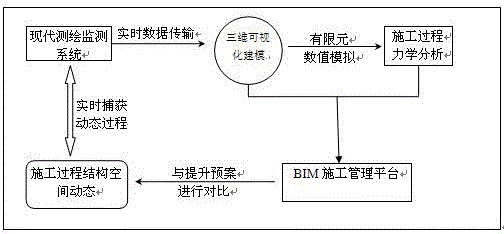

[0022] attached figure 1 An embodiment of the BIM-based method for time-varying finite element analysis of steel structure grid hydraulic lifting, this embodiment includes the following steps:

[0023] (1) According to the construction drawings, calculate the speed range of the hydraulic balance lifting process of the steel structure grid, simulate the corresponding virtual three-dimensional space, and formulate the lifting plan; carry out the pre-lifting of the steel structure grid, and record the relevant stress-strain data;

[0024] (2) Import the real-time steel structure hydraulic lifting BIM three-dimensional model into the finite element calculation software. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com