a frame structure

A frame structure and edge technology, which is applied in the field of frame structures, can solve the problems of difficult surface treatment and unguaranteed dimensional accuracy of aluminum frame structures, and achieve the effects of reducing surface treatment difficulty, ensuring dimensional accuracy, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

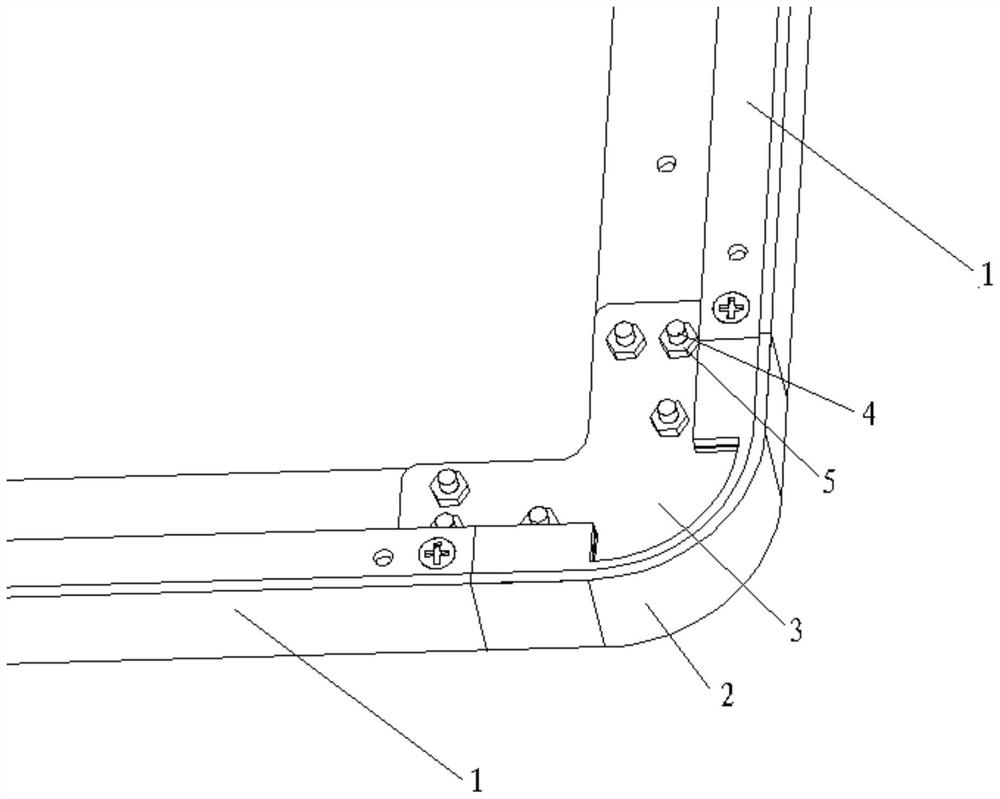

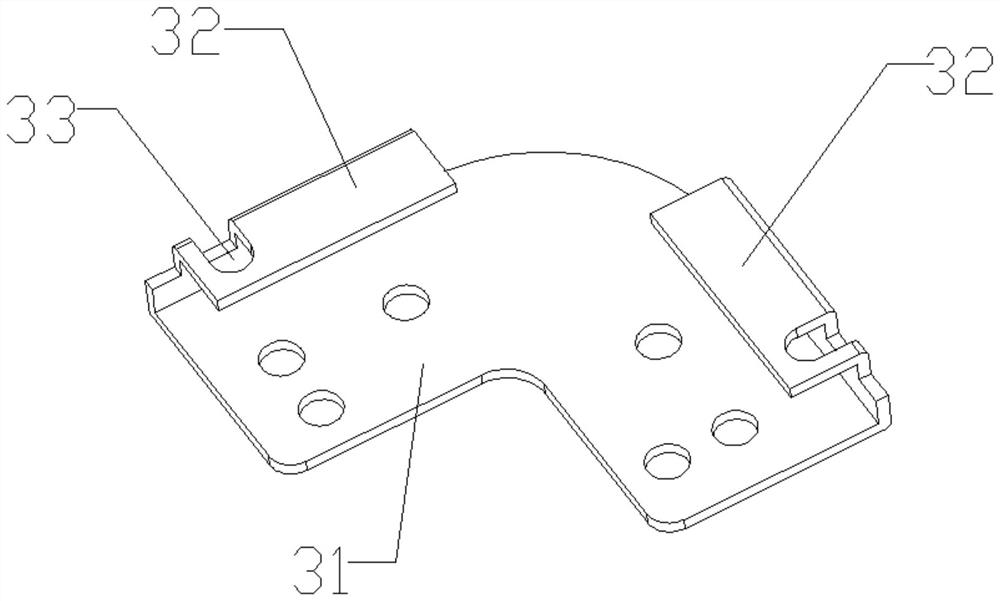

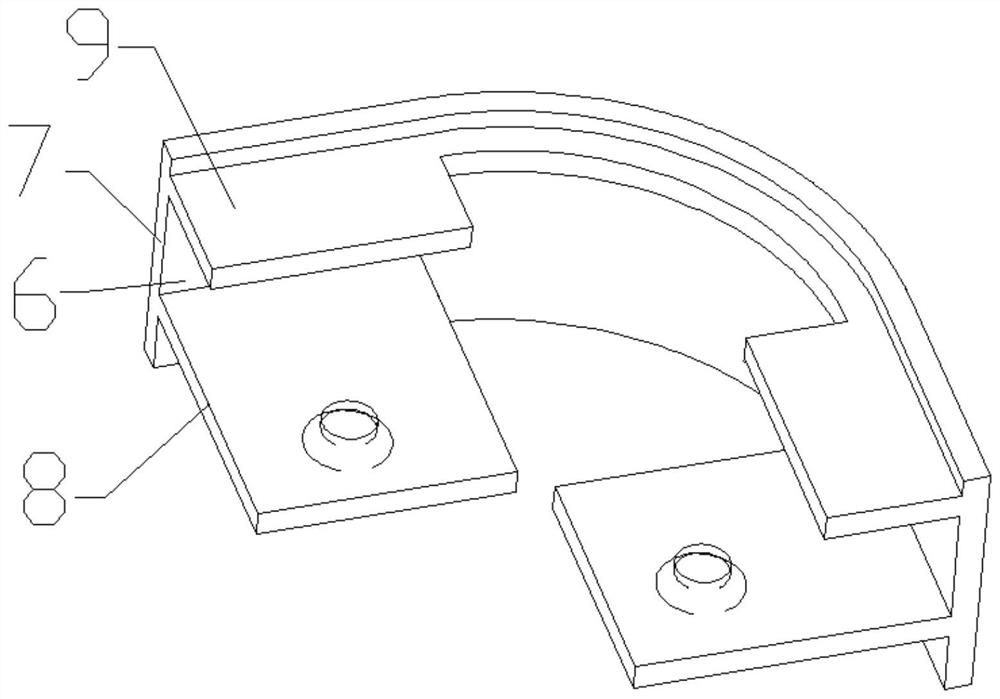

[0034] like Figure 1-6 As shown, a frame structure of the present invention includes

[0035] The side part 1 is a profile extending in a straight line, with a connecting section perpendicular to the extension direction;

[0036] The corner connecting assembly is arranged between the ends of the two adjacent side parts 1 arranged according to the included angle, and has arms extending according to the included angle and correspondingly connecting the corresponding side parts 1, and connecting the corresponding side parts 1 respectively. The arm part and the side part 1 are fixed together.

[0037] The above solution is the core solution of the present invention, because the frame structure is formed by connecting the side parts 1 and the corner connecting components manufactured separately, and the side parts 1 and the corner connecting components manufactured separately are relative to the overall bent frame. In terms of structure, the dimensional accuracy is more easily g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com