Method for reboring a shaft having a complex profile

A technology of re-boring and mandrel, applied to the parts of boring machine/drilling machine, the measurement of positioning in boring machine/drilling machine, manufacturing tools, etc., it can solve mechanical problems, complex problems, etc., and achieve simple manufacturing, simple operation, and reduced Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

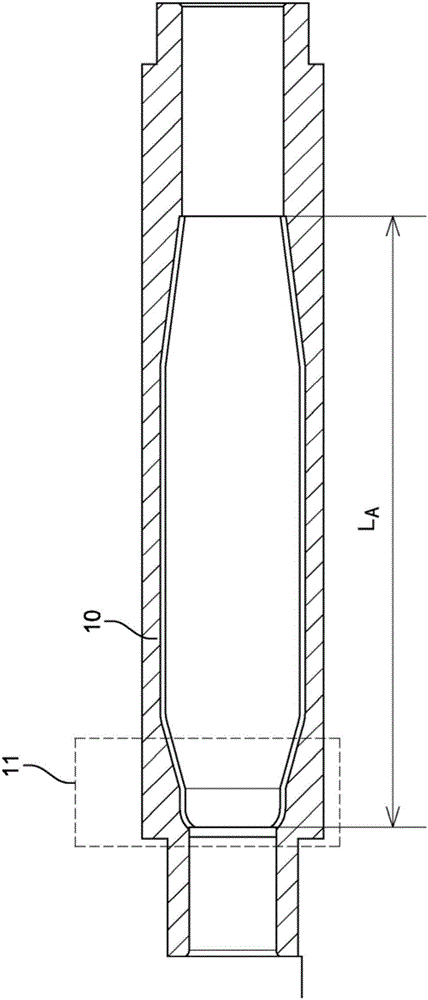

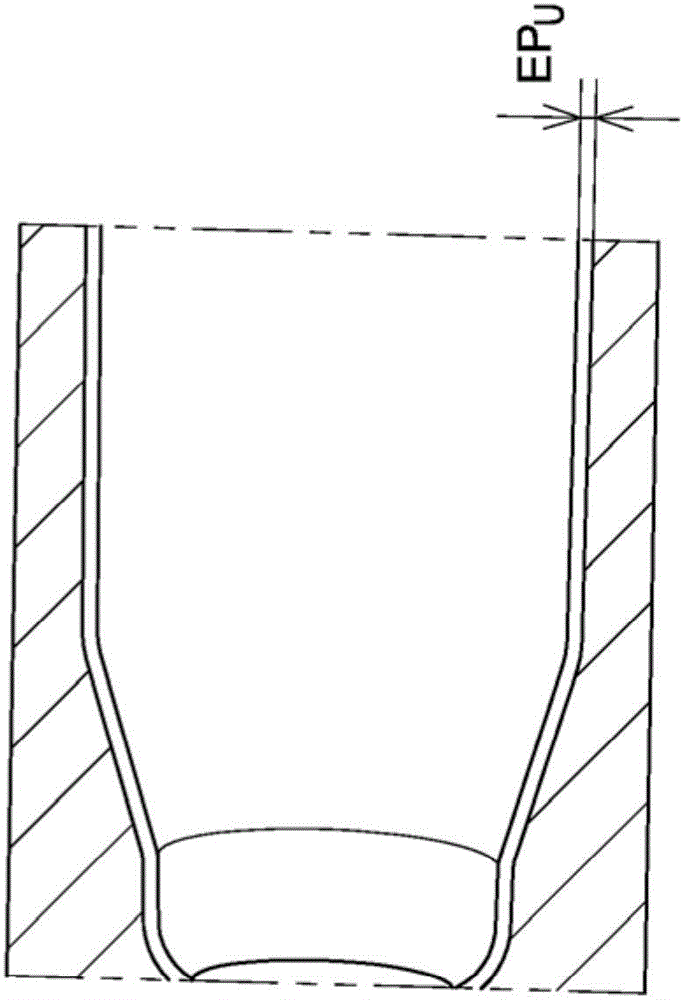

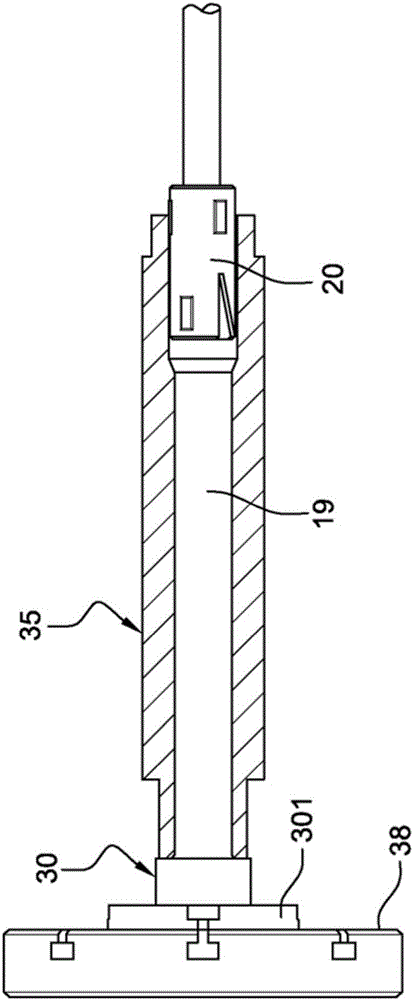

[0048] image 3 An example of the structure of the shaft 35 before calibration is shown. The shaft is machined to provide a pre-calibrated diameter 19 using a calibration head 20 to enable finishing operations using a finishing head. The guide assembly of the device proposed by the present invention makes it possible to repeat the drilling of the shaft 35 by the controlled pouring of resin into said shaft 35 in which the first hole has been drilled. The purpose is to reshape the cylindrical cavity 19 to form a guide channel for the calibration head and the finishing head. These devices include a plate 38 and a device 301 for securing the end piece 30 on which the shaft 35 is mounted.

[0049] Figure 4A An embodiment of the guide assembly of the present invention is represented, comprising a tube 32 made of 2mm-3mm incomparable steel mounted at each end centered on two end pieces 30,34.

[0050] The outer surface of the fixing tube 32 includes a coating which is anti-adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com