Crown reinforcements for aircraft tires

A technology for aircraft tires and reinforcements, applied to aircraft tires, reinforcement layers of pneumatic tires, tire components, etc., can solve the problems of centrifugal expansion profile control damage, tire cornering stiffness decrease, accelerated tread wear, etc., to reduce Effect of Cyclic Thermomechanical Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

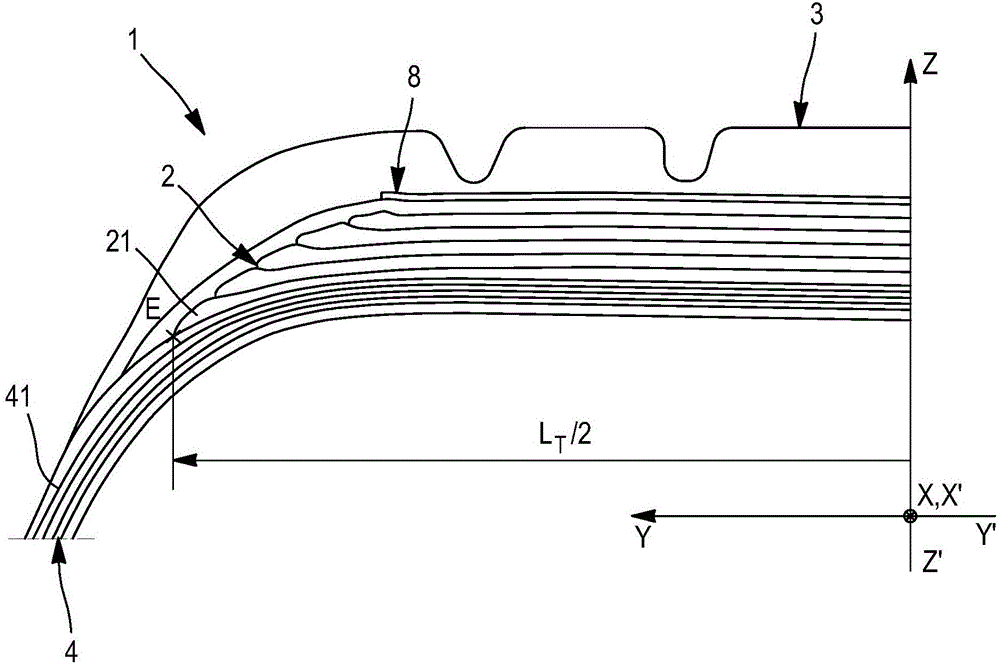

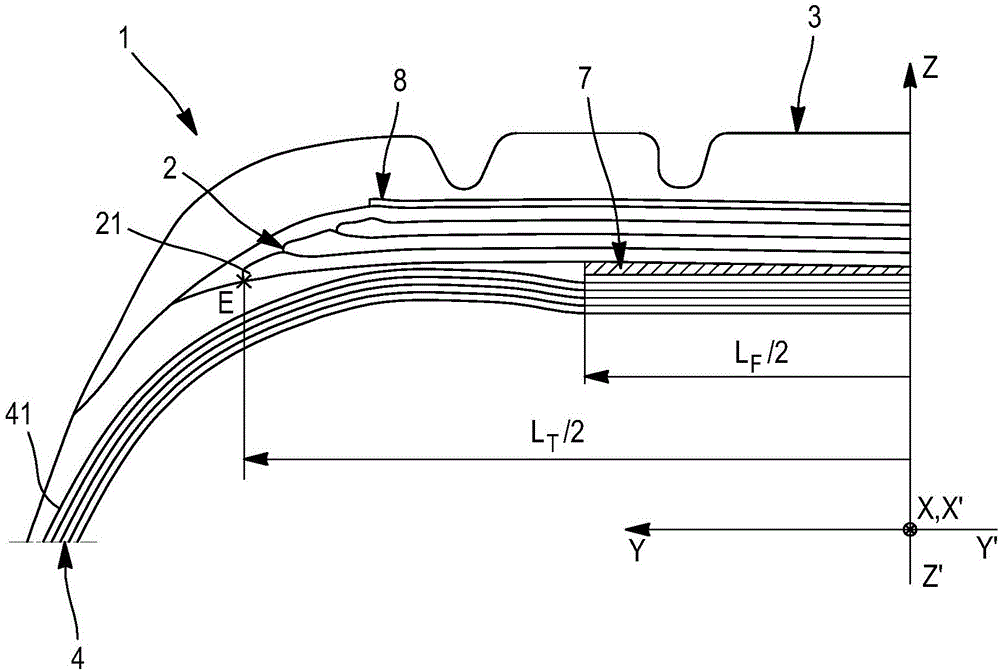

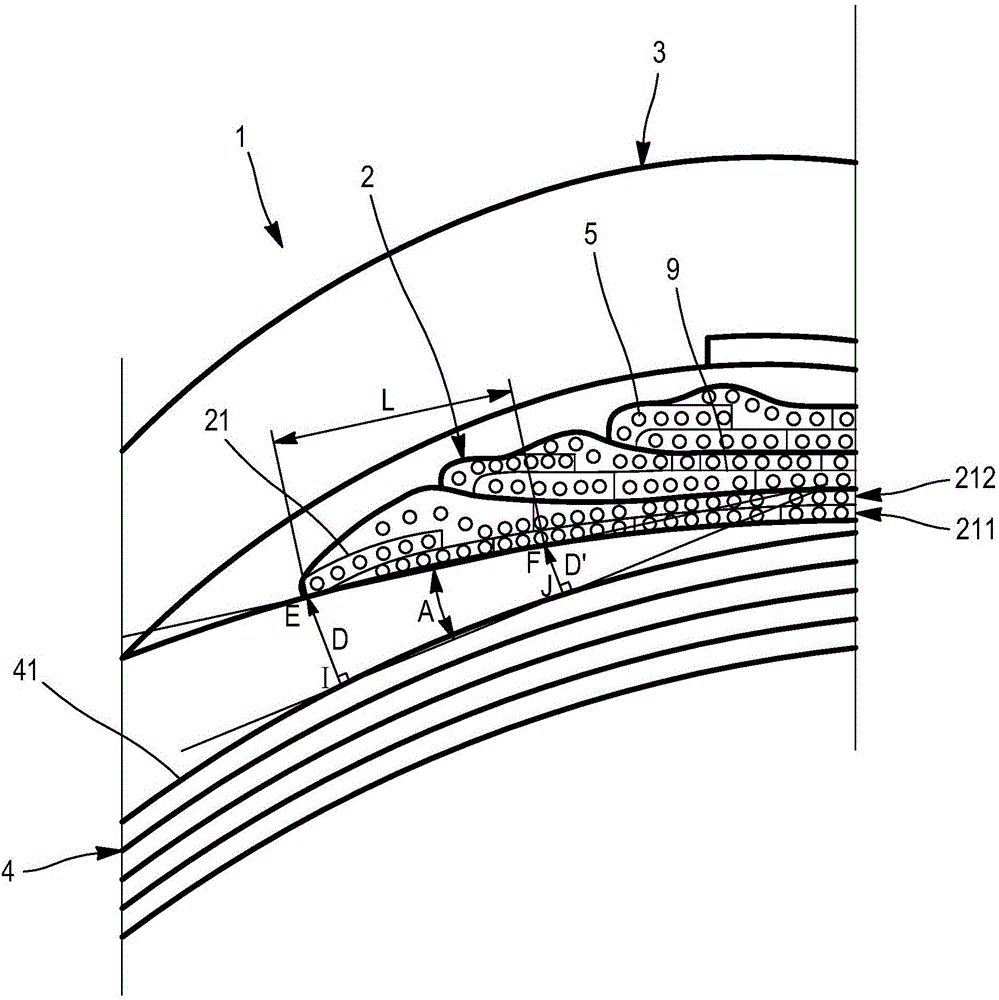

[0049] figure 1 shows, in a radial plane YZ passing through the axis of rotation YY' of the tire, a view of half of the cross-section of the crown of an aircraft tire 1 according to the prior art, comprising radially inside the tread 3 and at the The working reinforcement 2 on the radially outer side of the body reinforcement 4 . In the example given, the working reinforcement 2 comprises 5 working double plies 21, the radially innermost working double ply having a maximum axial width L measured between its two axial ends T . figure 1 Only the half width L between the axial end E of the radially innermost working double ply 21 and the equatorial plane XZ is shown T / 2. Each working double ply 21 consists at least partially of two radially superimposed working layers (211, 212) (cf. image 3 ). Each working layer (211, 212) comprises a textile reinforcement of the aliphatic polyamide type coated in an elastomeric material. The carcass reinforcement 4 comprises an overla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap