System for storing products, method for using such a system as well as a central control unit arranged to be operative in such a system

A technology of central control unit and storage location, applied in the field of central control unit and autonomous carriage, to achieve the effect of improving scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

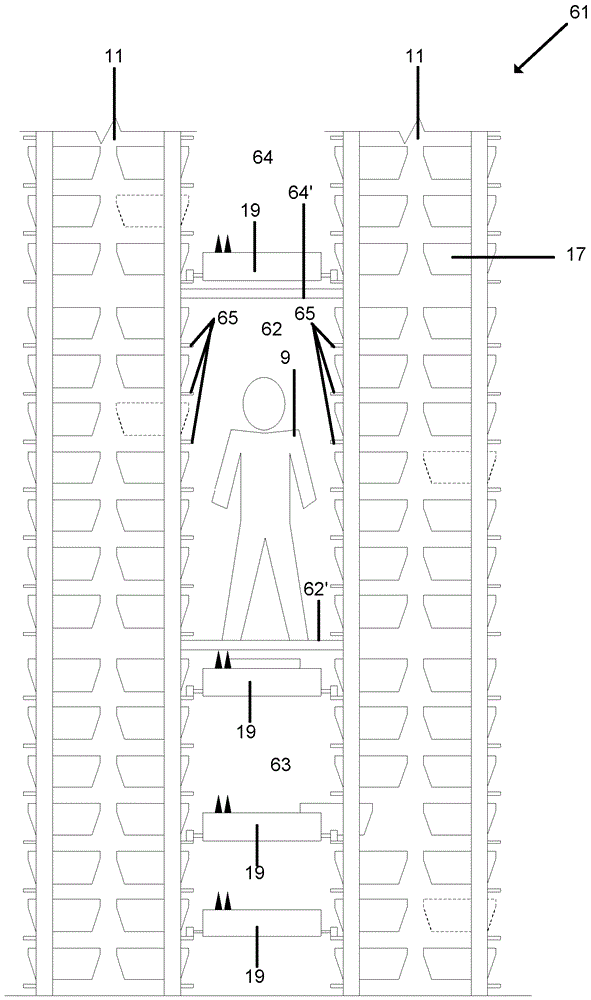

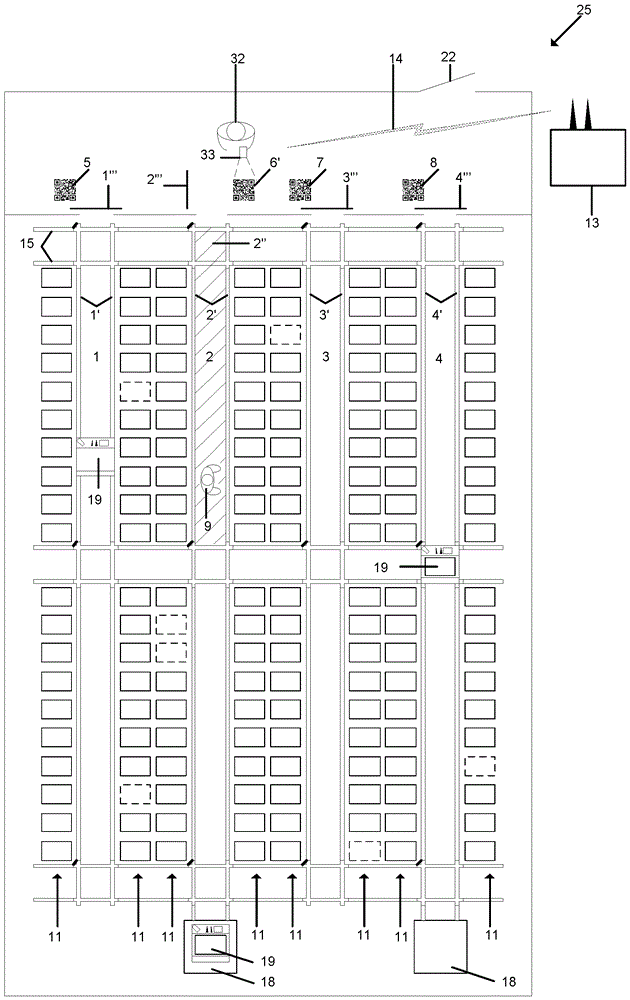

[0096] The system 25 for storing products comprises a plurality of racks 11 extending parallel to each other, wherein each rack 11 is provided with a storage location 16 positioned above each other. The storage location 16 is arranged for storing product boxes 17 . Each product box 17 is filled with a product or products, or is empty and is adapted to be filled with one or more products.

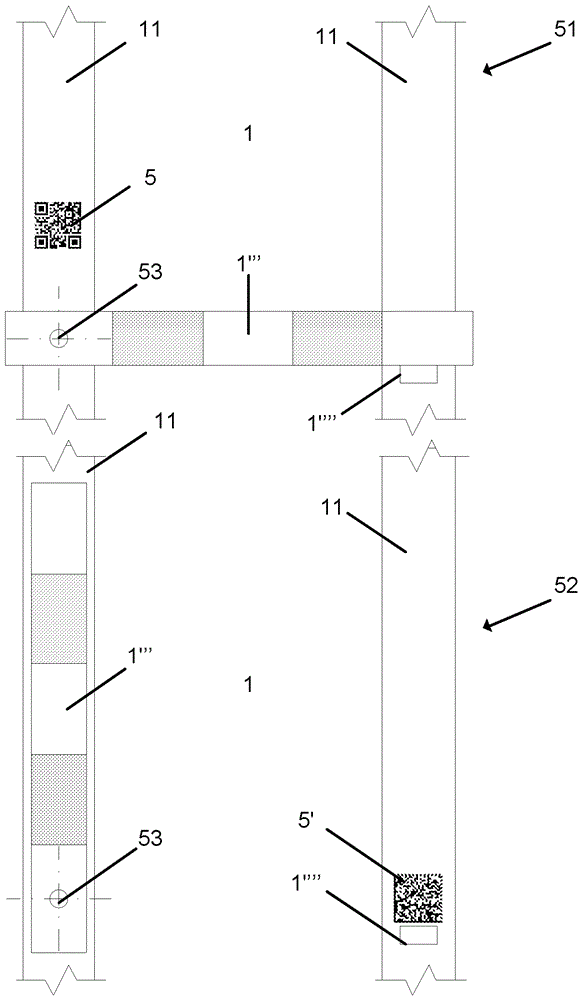

[0097] Aisles 1, 2, 3, 4 are formed between racks 11, that is, spaces between racks 11 are defined as aisles. The system also includes a boot system. The guide system comprises among others longitudinal guides 1', 2', 3', 4' extending in the aisles 1, 2, 3, 4, and horizontally transverse to the longitudinal guides 1', 2', 3', 4 'Extending transverse guides 15, and confluences 1'', 2'', 3'', 4'', the confluences 1'', 2'', 3'', 4'' in the longitudinal guides 1', 2', 3', 4' and transverse guides 15 cross each other. These junctions may include T-junctions as well as full junctions. T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com