Compressor assembly and assembly method therefor

A technology for compressors and components, applied in the field of compressor components, can solve the problems of increasing the risk of damage to the evaporating plate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

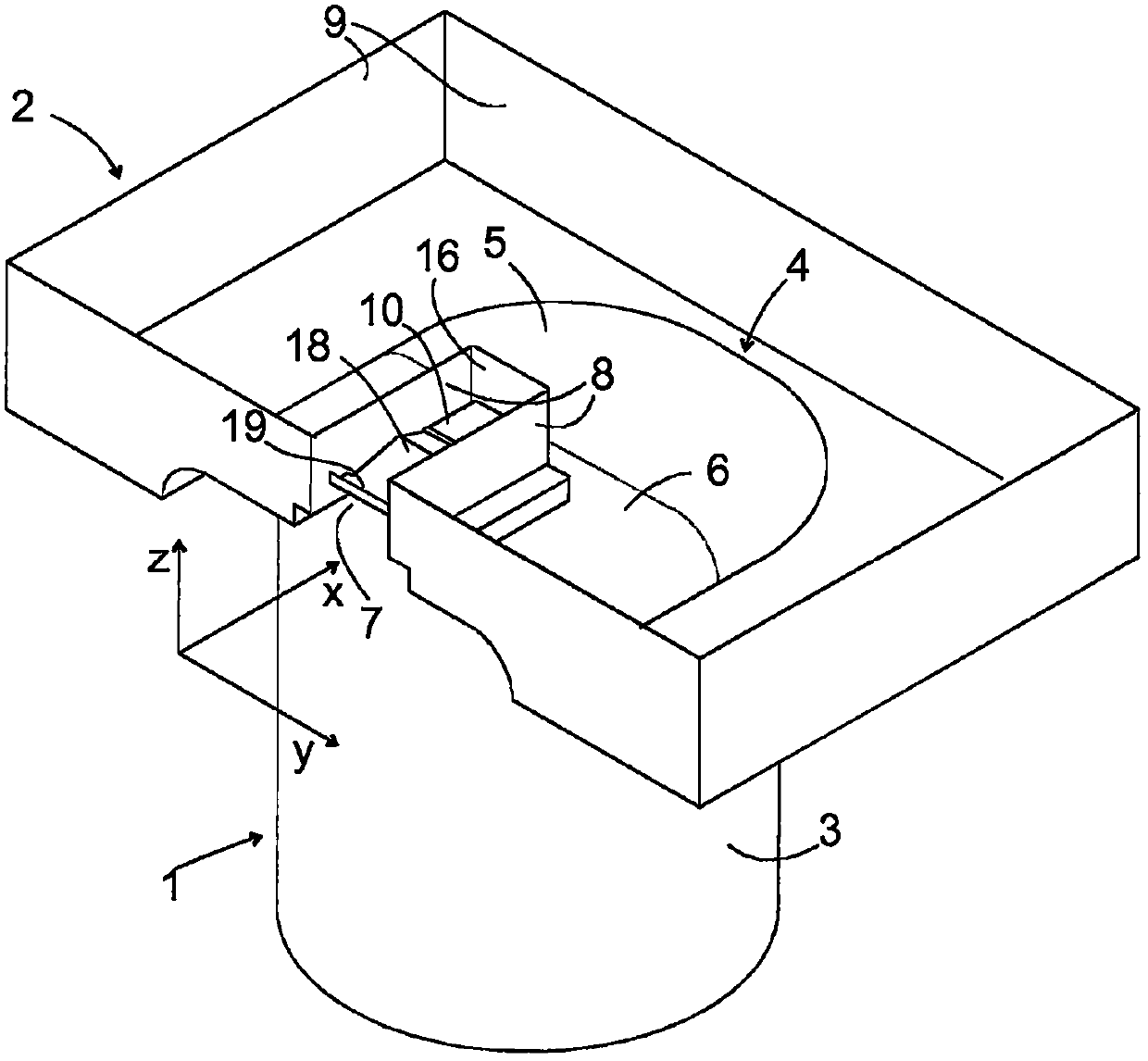

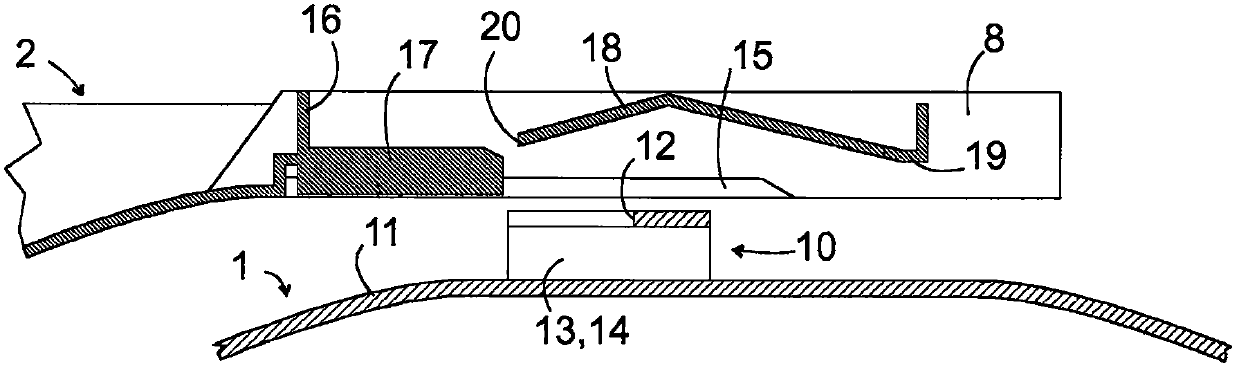

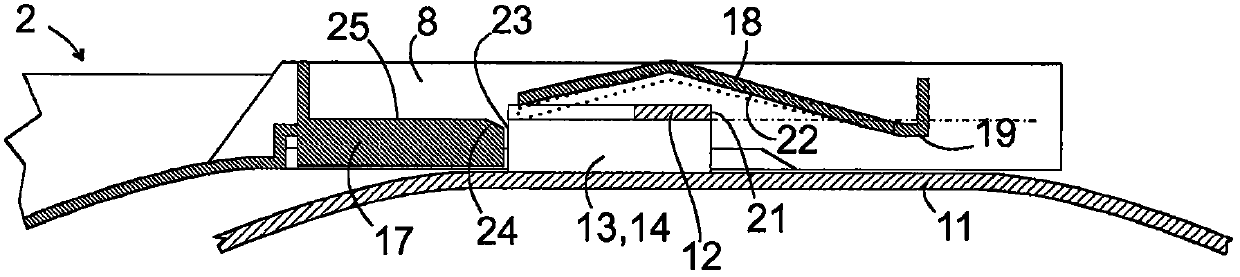

[0033] figure 1 The assembly according to the invention with a housing 1 and an evaporator plate 2 in which a compressor is installed is shown in a strongly schematic perspective view. The casing 1 basically has the configuration of a compact cylinder, wherein the casing 1 consists of figure 1 The transition from the visible outer surface 3 to the upper face of the housing, which is covered by the evaporator tray 2 in the figure, is rounded. In this case, the evaporator tray 2 essentially has the shape of a flat, upwardly open cuboid, on the bottom of which a bead 4 is formed. This bulge 4 comprises a semi-dome-shaped section 5 which rests tightly on the upper side of the casing 1 in order to achieve an efficient heat transfer from the compressor to the evaporator tray 2 and which The bulge comprises a section 6 terminating flush with the semi-dome-shaped section 5, the cross-section of which section 6 is constant in the direction indicated by X in the figure, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com