Method for enhancing continuous discharge performance of natural discharge manganese powder

A discharge manganese powder, a natural technology, applied in the field of metallurgy, can solve the problems of unfavorable long-term use by consumers, high content of harmful impurities, and low battery capacity, etc., and achieve the effect of increasing continuous discharge time, low cost, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

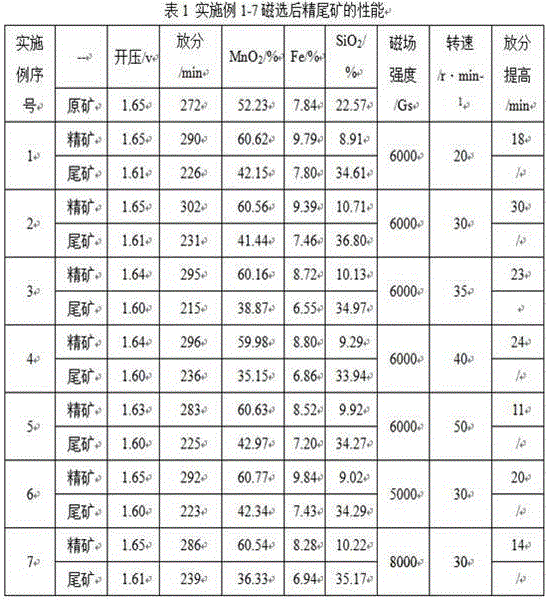

Embodiment 1

[0021] The raw ore natural discharge manganese powder made by powdering the raw ore natural discharge manganese sand has an opening pressure of 1.65 V and a continuous discharge of 272 minutes. MnO 2 content of 52.23%, Fe content of 7.84%, SiO 2 The content is 22.57%, and the particle size is ≤5 mm. The raw ore natural discharge manganese sand is powdered after magnetic separation by a permanent magnet magnetic separator with a magnetic field strength of 6000 Gs and a rotational speed of 20 r / min to obtain a magnetic separation concentrate natural discharge manganese powder. The opening pressure of the magnetic separation concentrate natural discharge manganese powder 1.65 V, continuous discharge for 290 min, MnO 2 content of 60.62%, Fe content of 9.79%, SiO 2 content of 8.91%, the opening pressure of the magnetic separation tailings obtained by magnetic separation is 1.61 V, and the continuous separation is 226 min. MnO 2 content of 42.15%, Fe content of 7.80%, SiO 2 The ...

Embodiment 2

[0023] The raw ore natural discharge manganese powder made by powdering the raw ore natural discharge manganese sand has an opening pressure of 1.65 V and a continuous discharge of 272 minutes. MnO 2 content of 52.23%, Fe content of 7.84%, SiO 2 The content is 22.57%, and the particle size is ≤5 mm. The raw ore natural discharge manganese sand is powdered after magnetic separation by a permanent magnet magnetic separator with a magnetic field strength of 6000 Gs and a rotational speed of 30 r / min to obtain a magnetic separation concentrate natural discharge manganese powder. The opening pressure of the magnetic separation concentrate natural discharge manganese powder is 1.65 V, continuous discharge for 302 min, MnO 2 content of 60.56%, Fe content of 9.39%, SiO 2 content of 10.71 %, the opening pressure of the magnetic separation tailings obtained by magnetic separation is 1.61 V, and the continuous discharge time is 231 min. MnO 2 content of 41.44%, Fe content of 7.46%, Si...

Embodiment 3

[0025] The raw ore natural discharge manganese powder made by powdering the raw ore natural discharge manganese sand has an opening pressure of 1.65 V and a continuous discharge of 272 minutes. MnO 2 content of 52.23%, Fe content of 7.84%, SiO 2 The content is 22.57%, and the particle size is ≤5mm. The raw ore natural discharge manganese sand is powdered after magnetic separation by a permanent magnet magnetic separator with a magnetic field strength of 6000 Gs and a rotational speed of 35 r / min to obtain a magnetic separation concentrate natural discharge manganese powder. The opening pressure of the magnetic separation concentrate natural discharge manganese powder is 1.64 V, continuous discharge for 295 min, MnO 2 content of 60.16%, Fe content of 8.72%, SiO 2 The content is 10.13%, the opening pressure of the magnetic separation tailings obtained by magnetic separation is 1.60 V, and the continuous discharge time is 215 min. MnO 2 content of 38.87%, Fe content of 6.55%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com