A simple shavings sorting device

A technology of sorting device and dispersing device, which is applied in the direction of solid separation, separating solid from solid with air flow, chemical instruments and methods, etc., can solve the problems affecting the subsequent processing of trays, achieve simple structure, improve production efficiency, The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

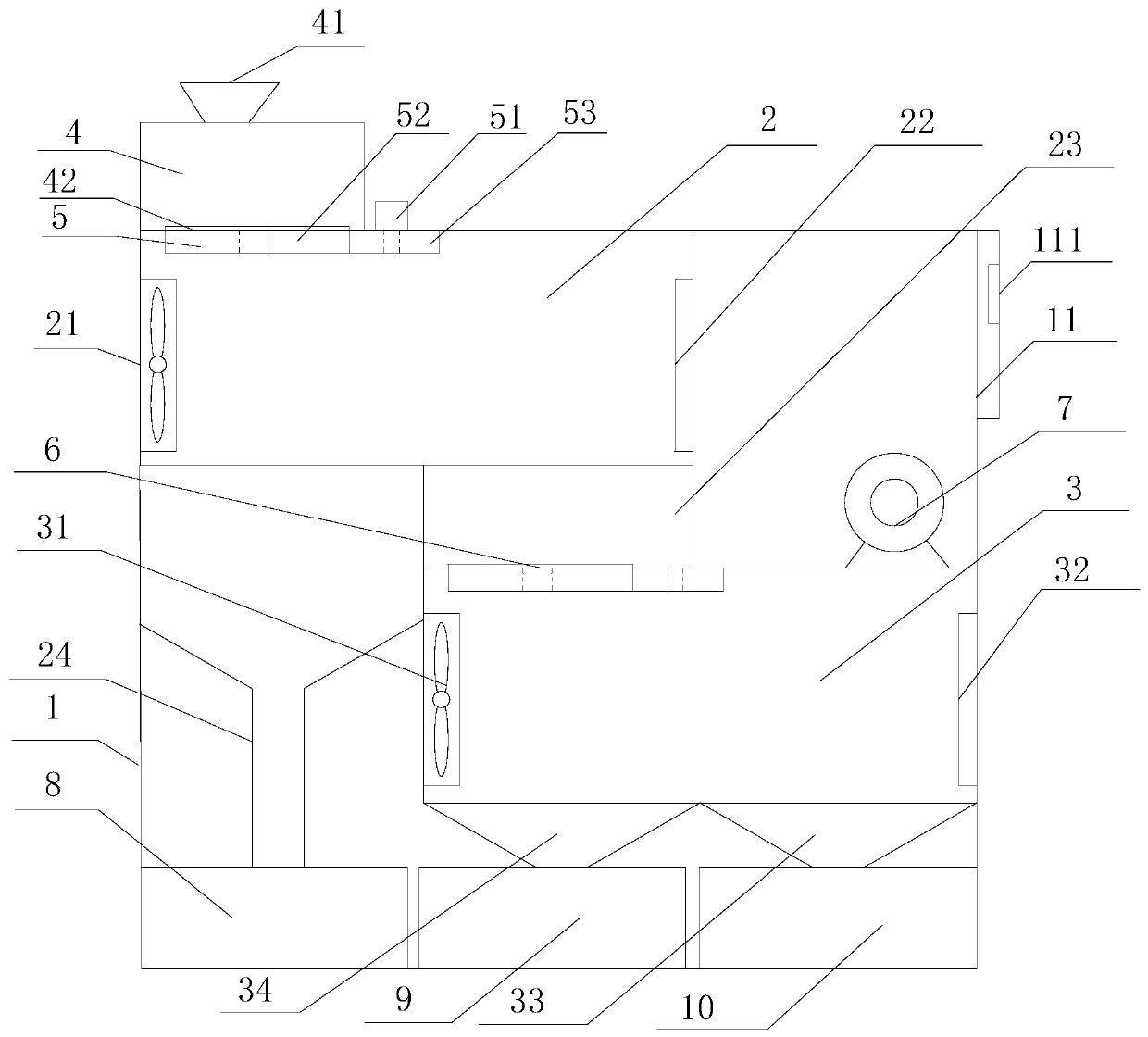

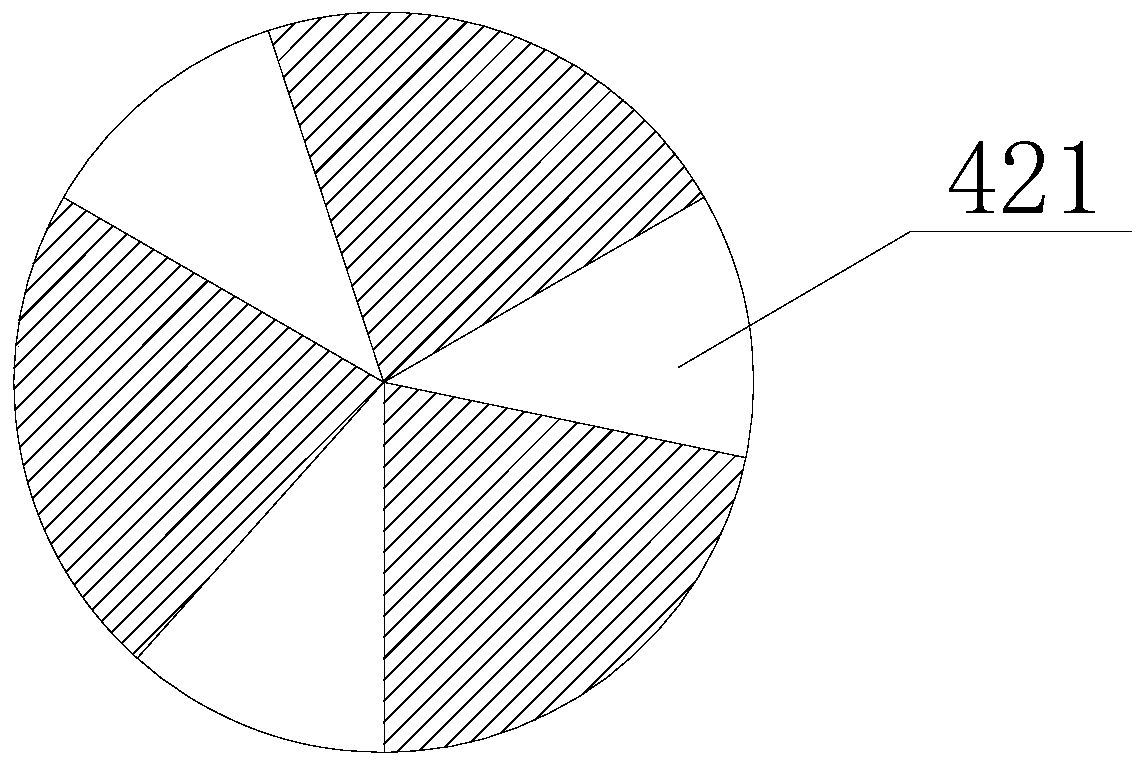

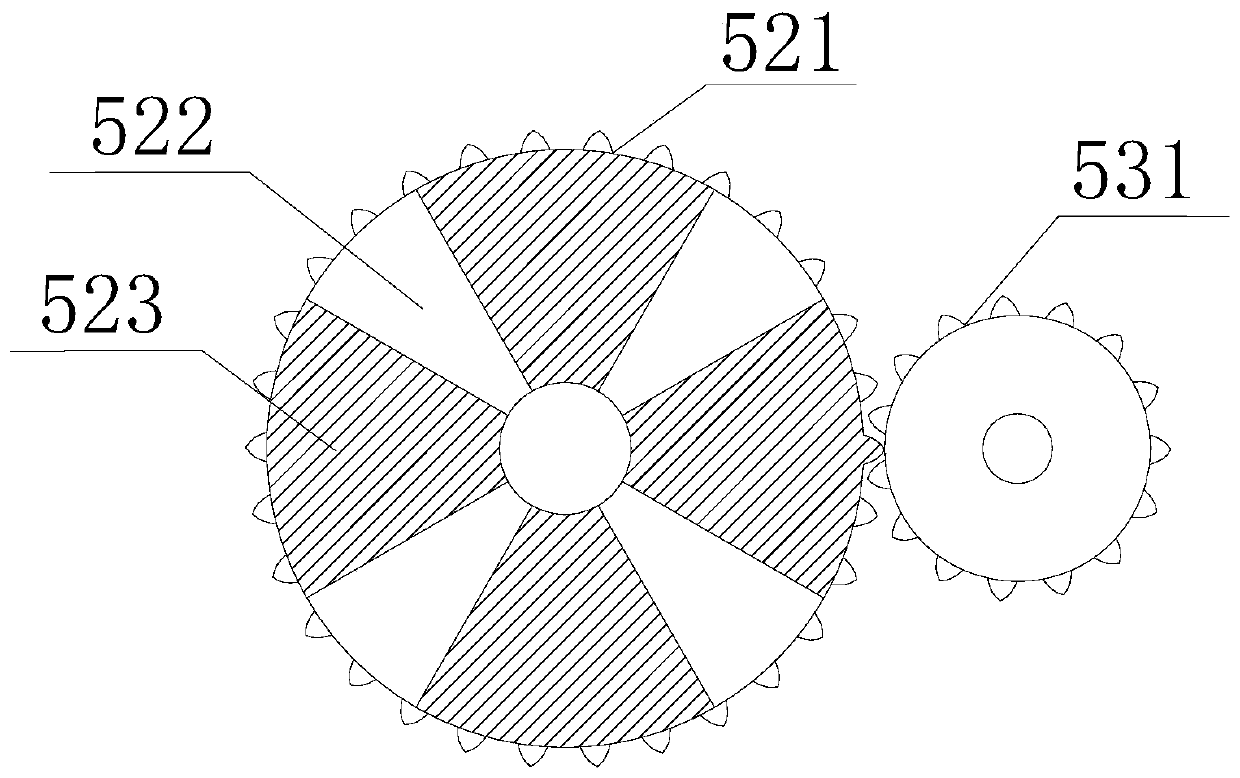

[0015] refer to figure 1 , figure 2 and image 3 A simple shavings sorting device of the present invention comprises a cabinet 1, a first screening chamber 2, a second screening chamber 3, a first storage box 4, a first dispersing device 5, a second dispersing device 6 and a motor 7. The top of the cabinet 1 is provided with a first material storage box 4, the first material storage box 4 is provided with a feeding funnel 41, the bottom of the first material storage box 4 is provided with a first discharge plate 42, and the first material storage box 4 is provided with a first discharge plate 42. A discharge plate 42 cooperates with the first dispersing device 5, and the first dispersing device 5 is provided with a rotating disk 52, and the rotating disk 52 is installed under the first discharging plate 42 through bearings, and the drive shaft 51 and Drive disc 53 cooperates, and described drive shaft 51 is connected with motor 7, and described turntable 52 rotates under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com