Multi-stage internal circulation system for realizing grinding of semi-finished powder

A circulation system and grinding technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problem that the grinding system does not have the function of multi-stage separation and powder selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

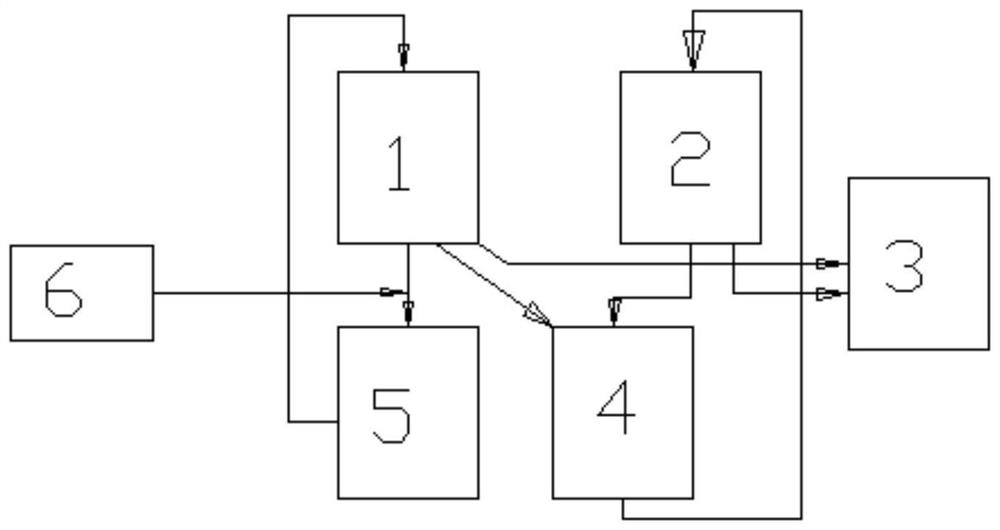

[0047] Embodiments of the present invention provide a multi-stage internal circulation system for semi-finished powder grinding, such as figure 1 As shown, the first screening module 1 and the second screening module 2 are included, and the three discharge ends of the first screening module 1 are connected with the finished product storage module 3, the roller press module 5, and the cement mill module 4 respectively, and the rollers The discharge end of the press module 5 is connected to the feed end of the first screening module 1; the discharge end of the cement mill module 4 is connected to the feed end of the second screening module 2, the two of the second screening module 2 The discharge end communicates with the feed end of the cement mill module 4 and the feed end of the finished product storage module 3 .

[0048] Wherein, preferably, the feed end of the roller press module 5 is connected to the feeding module 6, and the three discharge ends of the first screening mo...

Embodiment 2

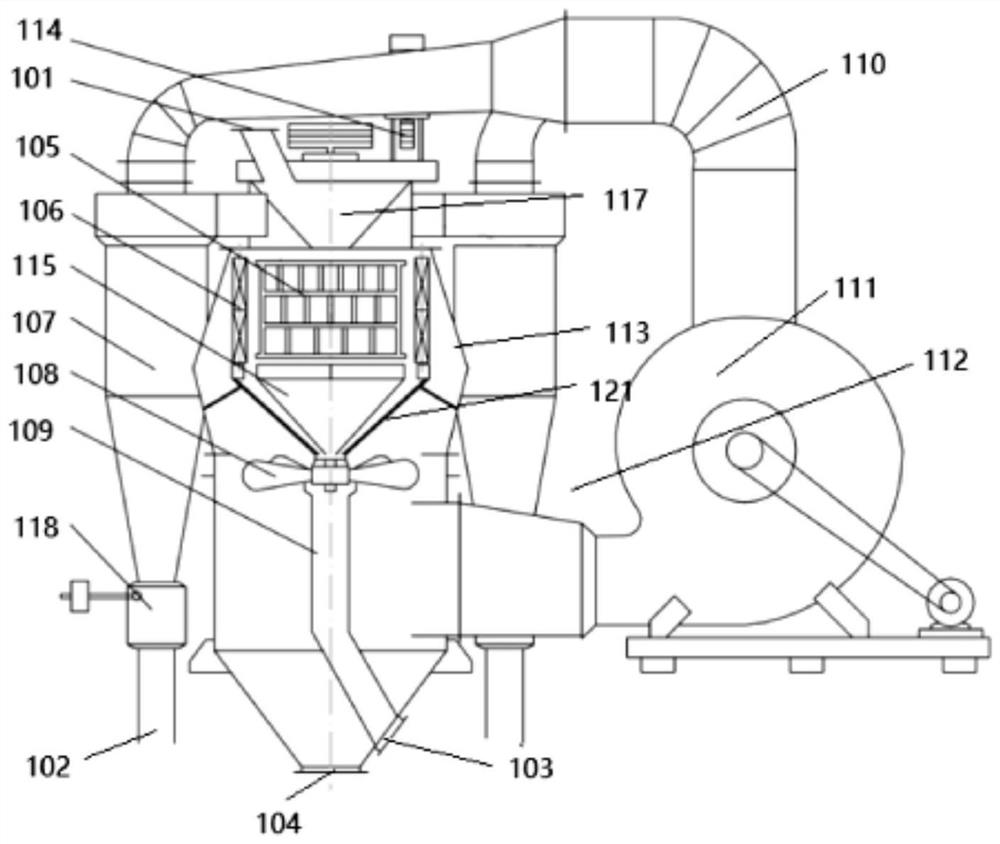

[0054] On the basis of above-mentioned embodiment 1, as Figure 2-3 As shown, the powder separator 112, the powder separator 112 includes: a body shell 113, the upper end of the body shell 113 is fixedly provided with a drive device 114, the bottom of the body shell 113 is set as a funnel, and the lower end of the body shell 113 is set There is a coarse powder discharge end 104.

[0055] Wherein, preferably, the upper surface of the body shell 113 is provided with a material inlet 101, the lower end of the material inlet 101 is connected to the material inlet chamber 117, and the lower end of the material inlet chamber 117 is connected to the rectifier rotor 105;

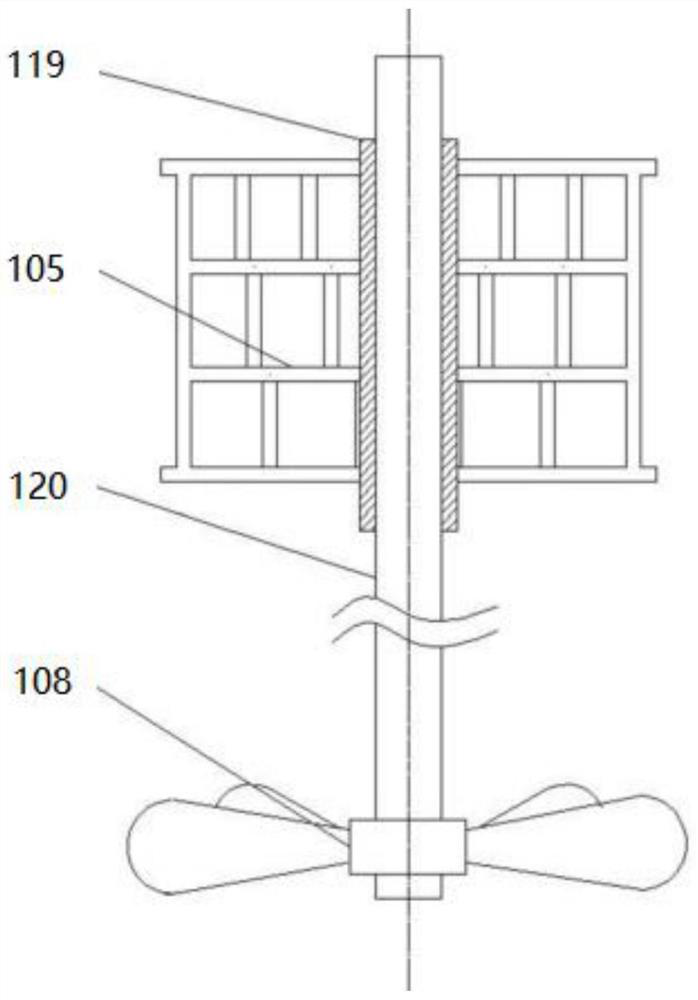

[0056] Drive the rotating shaft 120, the driving rotating shaft 120 is vertically arranged at the center of the body casing 113, and the upper end of the driving rotating shaft 120 extends out of the body casing 113;

[0057] Sleeve 119, the sleeve 119 is rotatably sleeved on the drive shaft 120, the upper end of t...

Embodiment 3

[0071] On the basis of Example 1, such as Figure 4-6 As shown, the multi-stage internal circulation system for semi-final powder grinding also includes a detection device 7, which is detachably arranged at the final powder discharge end 102 or at the feeding module 6 outlet, and the detection device 7 is provided with a first outlet 701 and a second outlet 702; when it is set at the final powder discharge end 102, the first outlet 701 communicates with the cement mill module 4, and the second outlet 702 communicates with the finished product inlet. The library module 3 is connected; when it is set at the outlet of the feeding module 6, the first outlet 701 is connected with the roller press module 5, and the second outlet 702 is connected with the first screening module 1;

[0072] Wherein, preferably, the detection device 7 includes a device housing 703, the upper end of the device housing 703 is provided with an opening 733, and the opening 733 communicates with the final p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com