System and process for recognizing and sorting aluminum scraps according to components

A sorting system and waste miscellaneous aluminum technology, applied in the direction of solid separation, chemical instruments and methods, separating solids from solids with airflow, etc., can solve the problems of complex components, difficult to directly batch and use, etc., and achieve sorting efficiency High, energy-saving and consumption-reducing effects and huge social benefits, the effect of realizing primary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

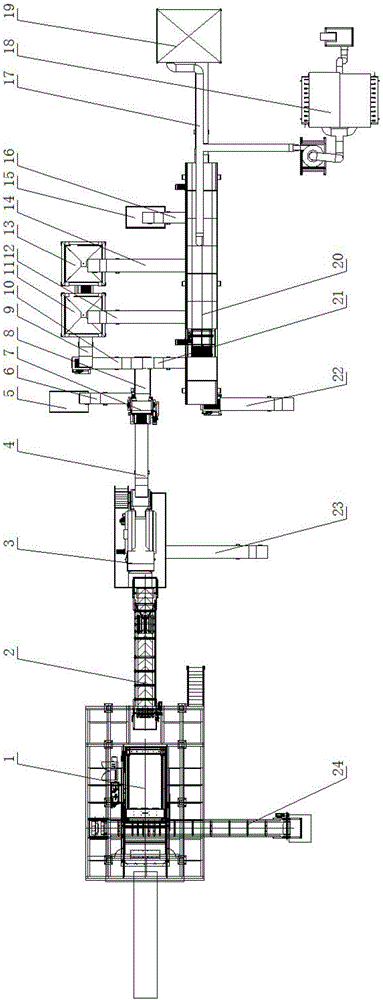

[0024] A sorting system for identifying waste miscellaneous aluminum according to its composition, comprising a vibrating hopper 19, a drum sorter 20, a magnetic separator 7, an eddy current sorter 3 and a LIBS sorter 1 connected in sequence, the vibrating hopper and the The inlets of the drum sorter are connected by a closed conveyor belt 17, and a dust removal device 18 is installed on the closed conveyor belt to remove light non-metals in the aluminum material. There are 20mm, 40mm, 80mm and 120mm filter screens in the drum sorter from the inlet to the outlet in turn, and a dust removal pipe is set above the drum sorter cover. The dust removal pipe is connected to the dust removal equipment to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com