Micro-wool conductive relief fabric

A conductive fabric and conductive convex technology, which is applied in the field of textile fabrics and fabrics, can solve the problems of no layering and single fabric structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

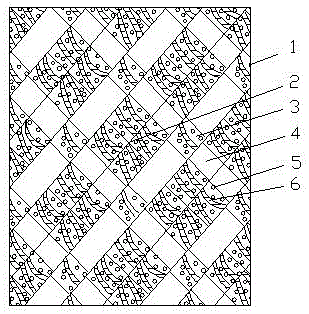

[0010] see figure 1 , the present invention relates to a micro-hair conductive embossed fabric, which includes a fabric body 1, the upper surface of the fabric body 1 is provided with several stripes 2, large squares 3 and small squares 4, the stripes 2 are arranged in parallel and equidistant, And inclined at an angle of 45 degrees, the stripes 2 are in groups of three, the large squares 3 occupy the first two rows of stripes 2, and are inclined at an angle of 45 degrees, the small squares 4 occupy the last row of stripes 2, and the large Blocks 3 and small blocks 4 are staggered and equidistantly arranged, and the large blocks 3 and small blocks 4 are provided with some convex points 5 and convex lines 6, and the height of the convex lines 6 is higher than the height of the convex points 5, and the The big square 3 comprises four squares equal in size to the small square 4 .

[0011] The lower surface of the fabric body is provided with a lining fabric layer, and the lining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com