Conductive micro-hair wear-resistant fabric

A wear-resistant fabric and micro wool technology, applied in the field of fabrics and textile fabrics, can solve the problems of poor wear resistance, poor air permeability, easy to wear, etc., and achieve the effects of low cost, improved tensile strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

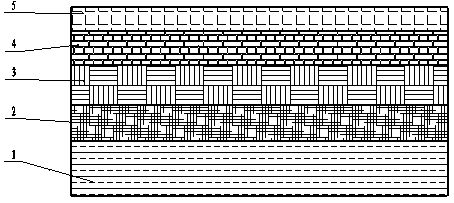

[0015] see figure 1 , a microhair conductive wear-resistant fabric, including an inner layer, the inner layer is provided with a base cloth layer, a breathable layer, a wear-resistant layer and a coating layer in sequence, and each layer is bonded and fixed by polyurethane glue; the inner layer It includes first warp yarns and first weft yarns, the first warp yarns are woven with cotton fibers, the first weft yarns are woven with spandex fibers; the base fabric layer includes second warp yarns and second weft yarns, and the second warp yarns are It is woven with bamboo fiber, and the second weft yarn is woven with acrylic fiber; the breathable layer is woven with a three-dimensional mesh superfine fiber base cloth; the wear-resistant layer includes a third warp yarn and a third weft yarn, and the first The three warp yarns are woven with sea-island fibers, and the third weft yarn is woven with holy hemp fibers; the coating layer is polytetrafluoroethylene coating.

[0016] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com