Installation structure for motor type light pattern transformation device

A technology of installation structure and conversion device, which is applied in the direction of signal device, optical signal, transportation and packaging, etc., and can solve the problems of sunlight focusing and baking failure, inconvenient use, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

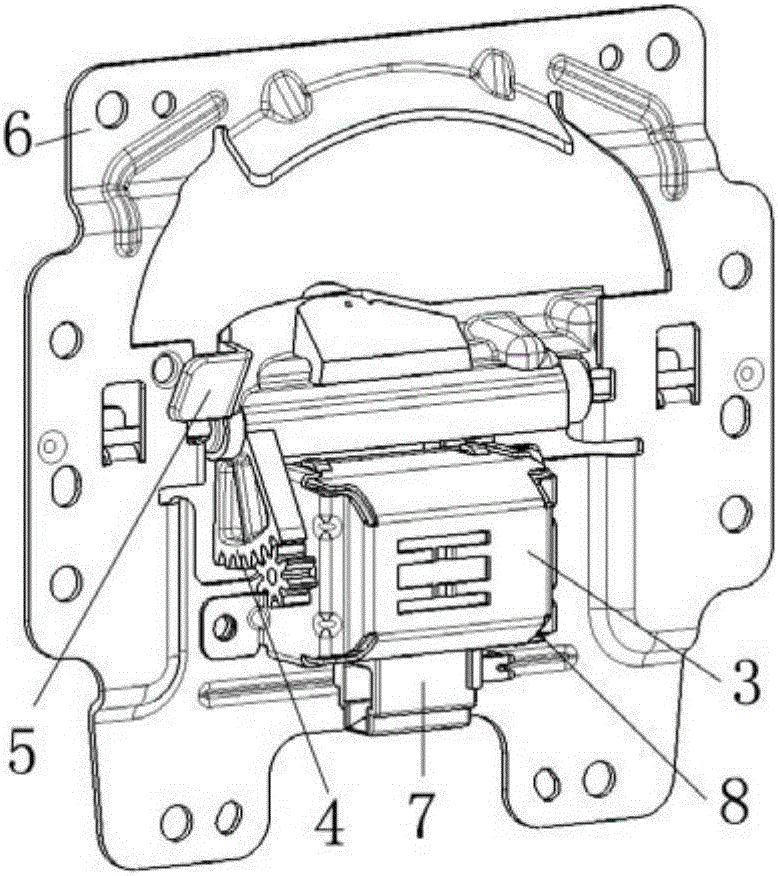

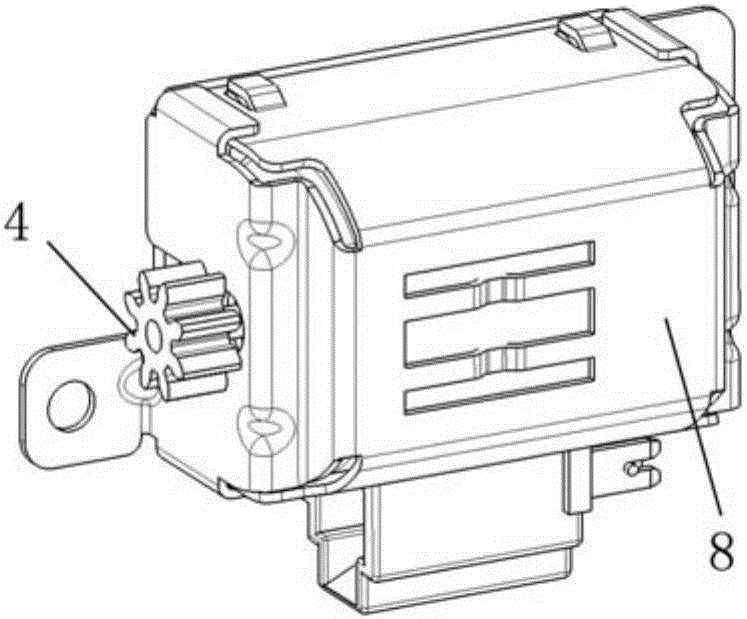

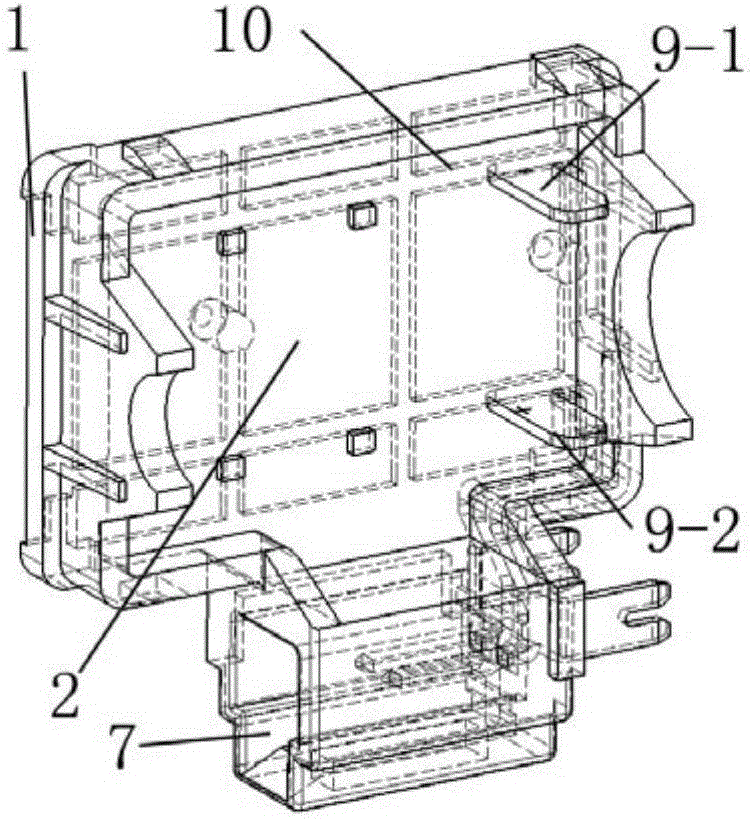

[0062] An installation structure of a motor-type optical type conversion device, comprising: a metal casing provided with a spur gear transmission mechanism, a motor for driving the spur gear transmission mechanism, and an installation structure casing, which is fixed on the installation structure casing and is located in the automobile headlight The front, the holder 6 fixed on the reflector and the movable sunshield 5 arranged on the holder 6, the movable sunshield can be driven by a spur gear transmission mechanism, with its bottom as a fulcrum in front of the car. The front direction of the lamp is flipped up and down, and the shading switch is carried out in coordination with the light type transformation.

[0063] The housing of the installation structure is integrally injection-molded with plastic and metal; the upper and lower sides of the housing of the installation structure are respectively provided with two plastic clamping feet for clamping with the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com