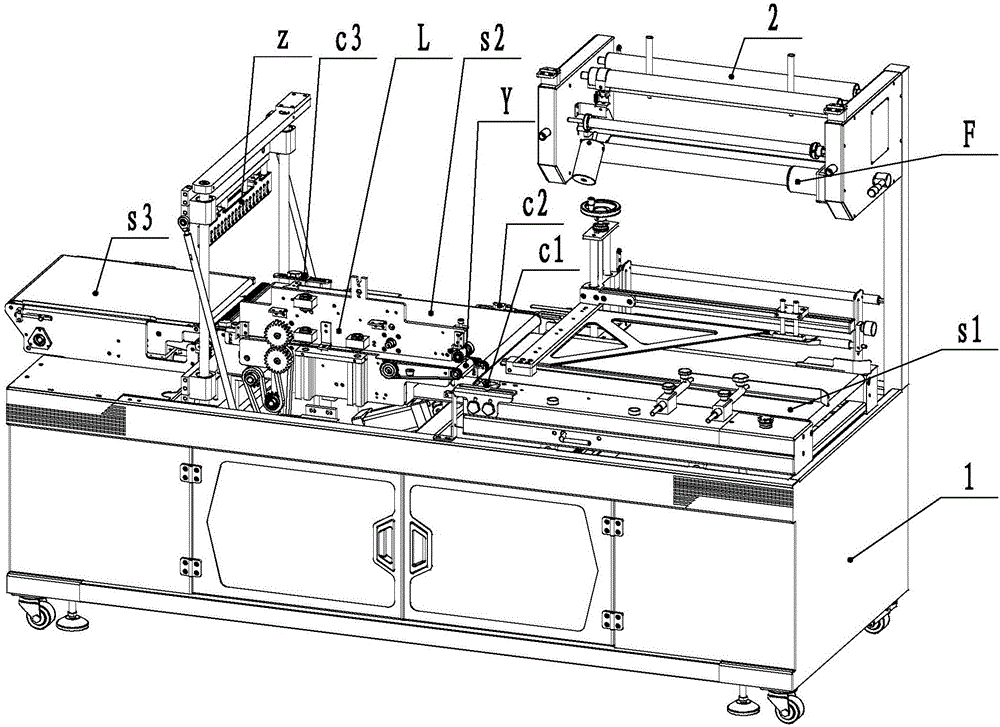

Thin film sealing and cutting packing method based on sealing and cutting packing machine

A packaging method and packaging machine technology, applied in packaging sealing/fastening, packaging material feeding device, packaging, etc., can solve the problems of different films, affecting packaging quality, etc., and achieve the effect of reducing package leakage and uniform products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

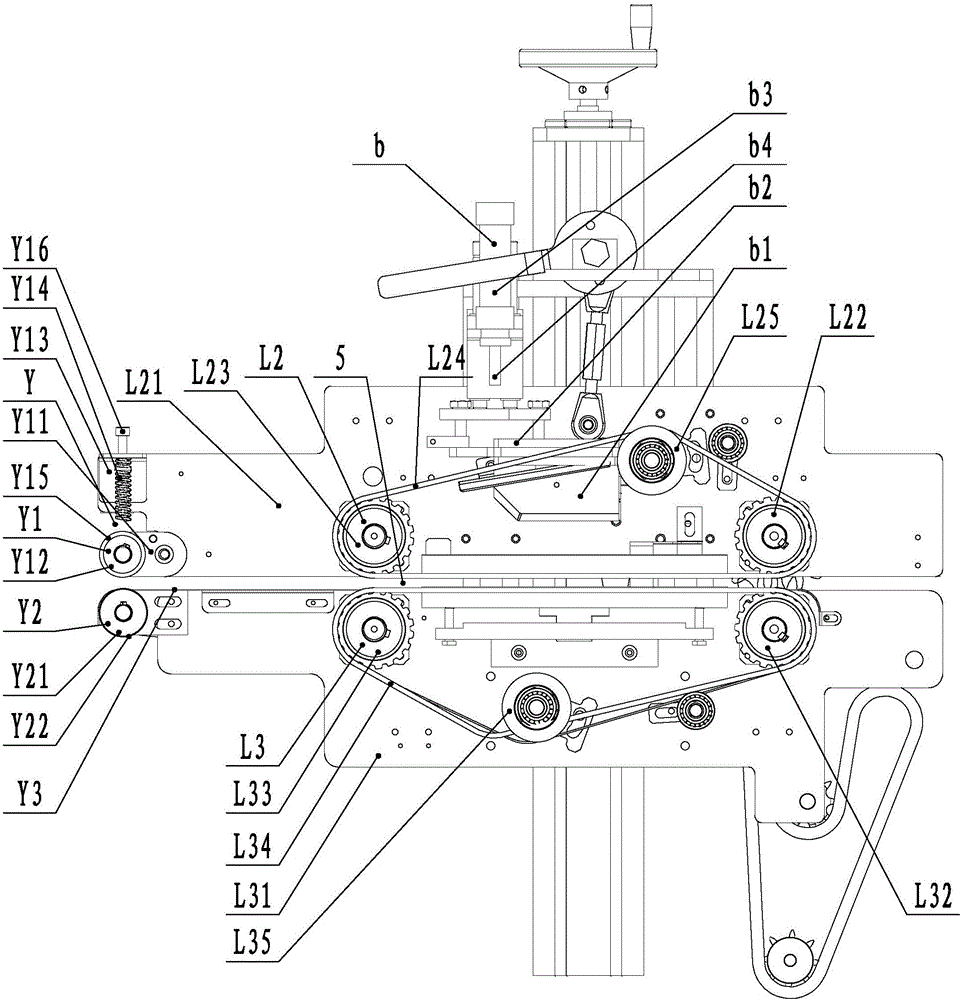

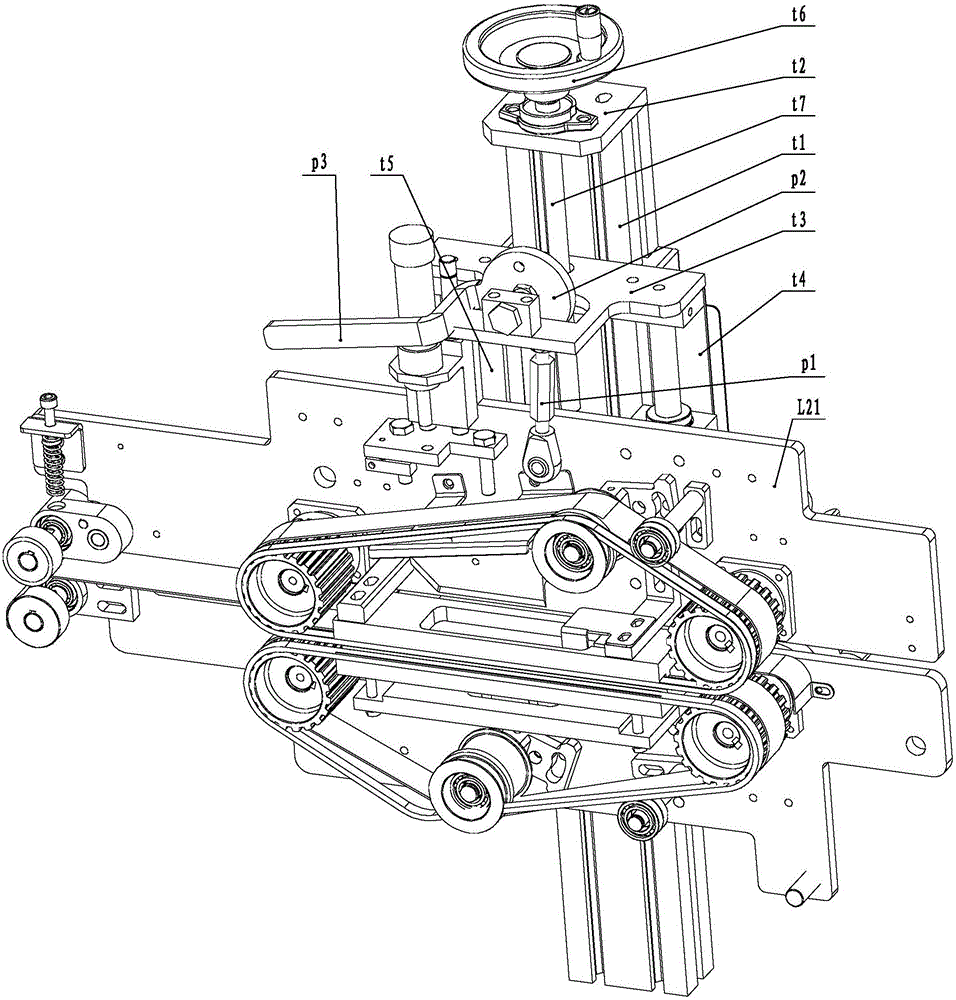

[0053] As a specific embodiment of the improvement, it also includes a film punching step: use a punching device to open air holes on the film that has just been separated from the film roll 2;

[0054] The piercing device is arranged close to the film roller 2, and the piercing device includes a mounting rod z1, a connecting seat z2, a mounting shell z3, a pin wheel z4, and a spring z5, and the mounting rod z1 is fixedly installed on the frame 1, so that The connecting seat z2 is mounted on the mounting rod z1, the mounting shell z3 is rotatably mounted on the connecting seat z2, one end of the spring z5 is fixedly connected to the connecting seat z2, and the other end is fixedly connected to the mounting shell z3. The mounting shell z3 is provided with a clamping groove, and the spring z5 pulls the mounting shell z3, so that the groove wall of the clamping groove is against the connecting seat z2, or the inner wall of the mounting shell z3 is against the connecting seat z2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com