Jacquard chain warping machine and method for operating same

A technology of jacquard chains and warping machines, which is applied in warping machines, textiles, papermaking, and tool manufacturing, and can solve problems such as yarn layer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

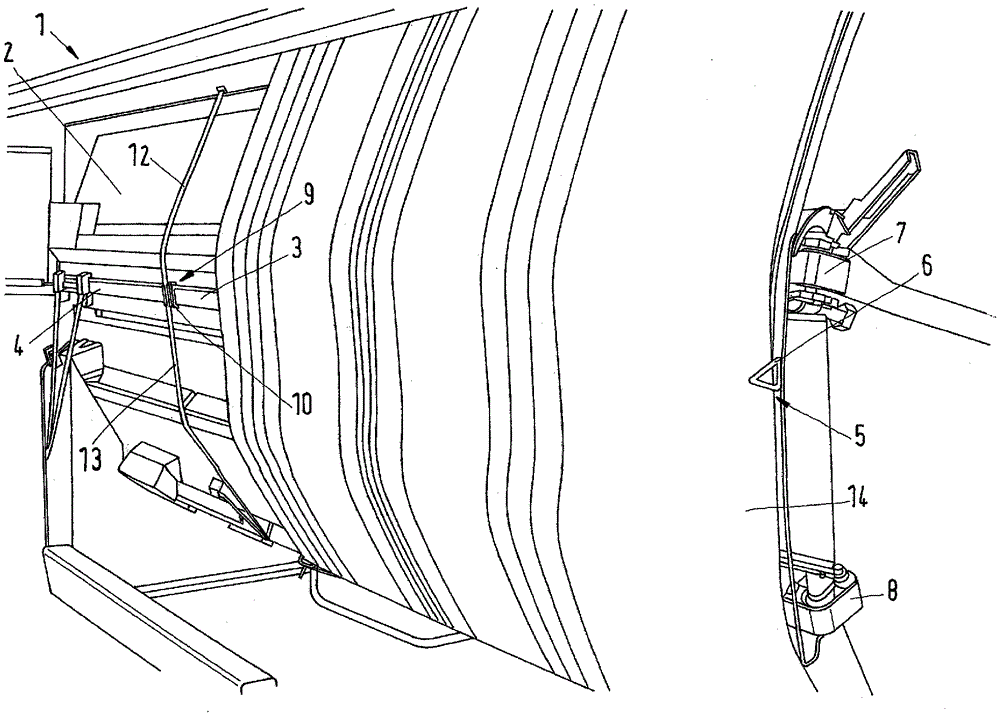

[0032] figure 1 A Jacquard chain warper 1 with a warping cylinder 2 is shown. The warping cylinder 2 has warping rods 3 . The warping rod 3 is fastened to the warping cylinder 2 with a fixed axial end 4 . The distribution rod 3 has a second end. The second end is designed as a free axial end 5 . The free axial end 5 has a hook 6 .

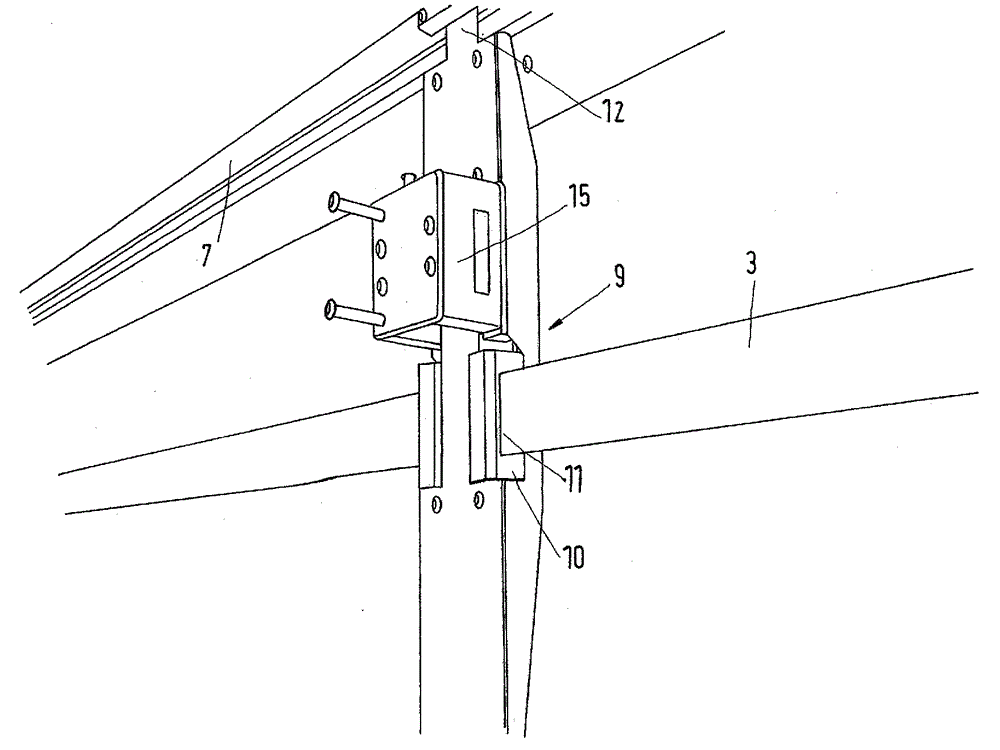

[0033] Furthermore, the warping cylinder 2 has a first conveying surface 7 and a second conveying surface 8 . In this case, the first conveying surface 7 and the second conveying surface 8 cooperate with a holding device 9 .

[0034] The holding device 9 has a holding element 10 . The holding element 10 releases the receiving space 11 .

[0035] The holding device 9 cooperates with the first conveying surface 7 and the second conveying surface 8 via a first tensioning element 12 and a second tensioning element 13 .

[0036] The holding device 9 is fastened on the warping cylinder 2 at a distance from the warping cover 14 .

[0037] The fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com