Automatic construction device for net hanging and spray-seeding on highway

A technology for highways and construction equipment, which is applied to clay mixing equipment, clay preparation equipment, and sales of raw material supply equipment, etc. It can solve problems such as affecting the appearance, slow construction speed, and unstable quality, so as to save construction costs and increase production efficiency. , good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

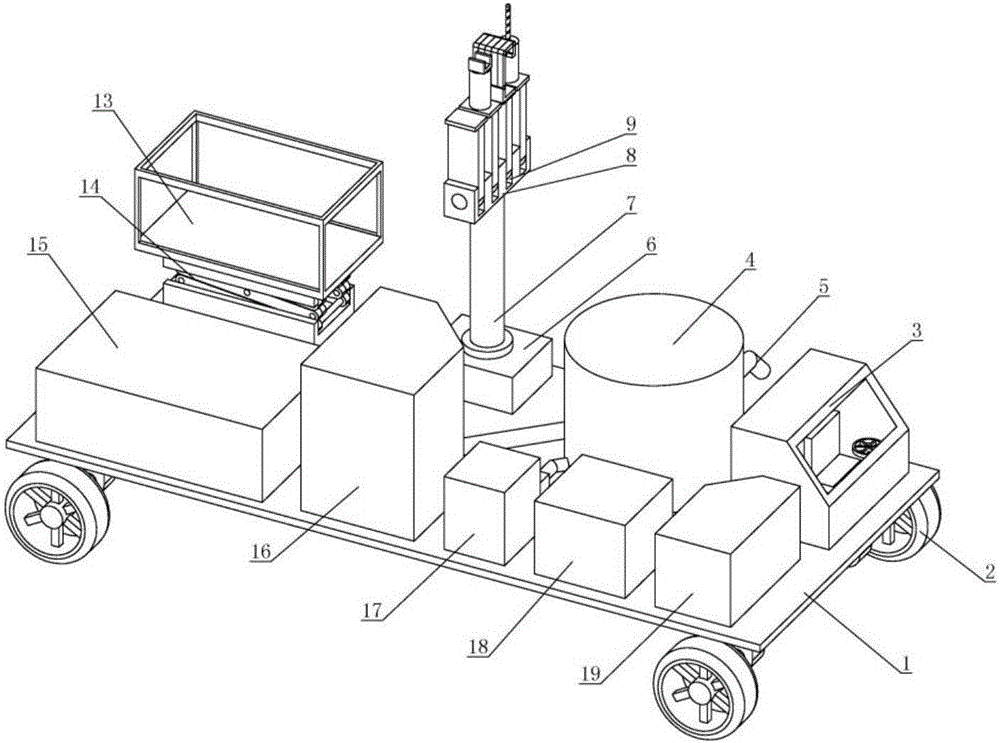

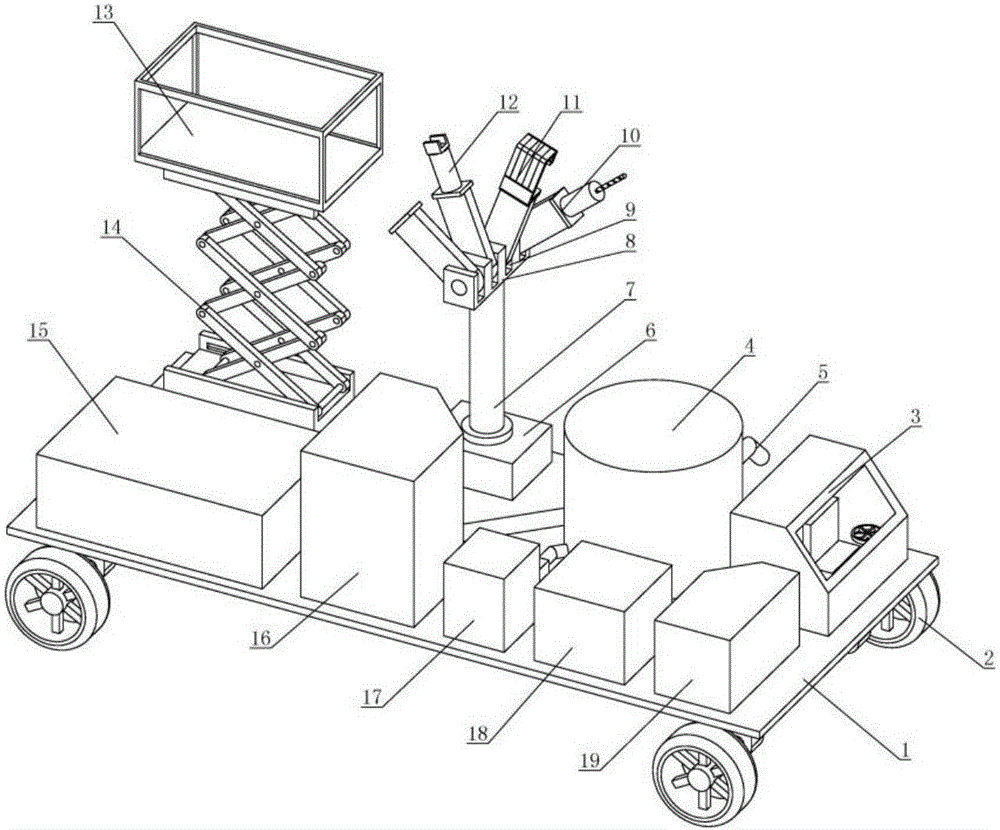

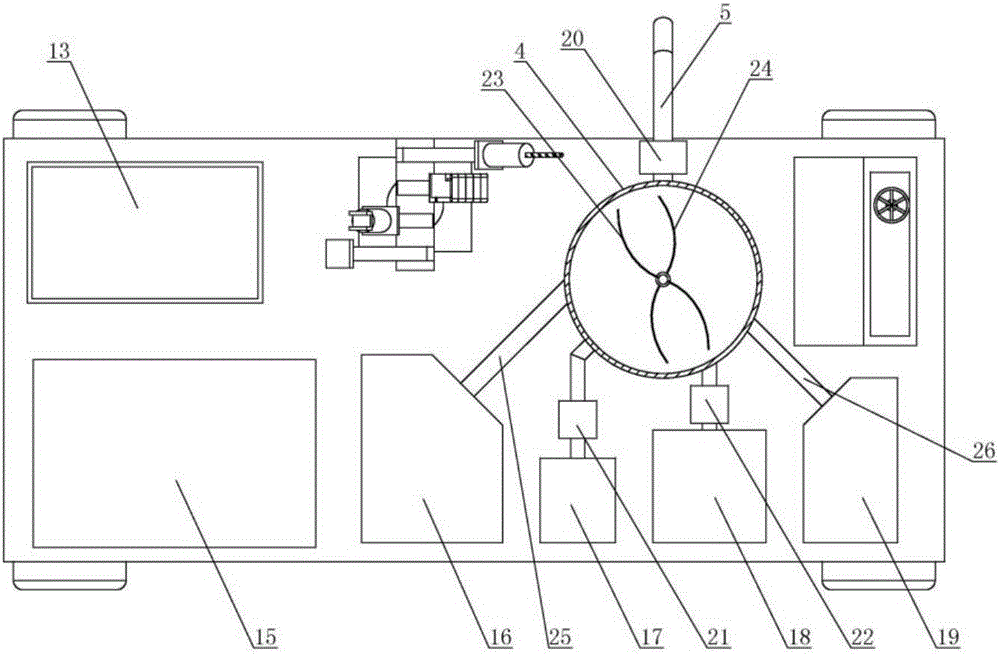

[0021] Such as Figure 1-6 As shown, the present invention replaces manual labor by machinery, and the work of the assembly line effectively improves work efficiency and work accuracy. The present invention includes a car body 1 and a car body power device 15, and the car body 1 is provided with an operating room 3 and Walking wheel 2, described car body power unit 15 is made up of engine, transmission box and the driving axle that is connected with the driving shaft of walking wheel 2, is characterized in that also comprises drilling hole hanging net mechanism, auxiliary lifting mechanism, mixing system and with The transfer case to which the engine is connected;

[0022] Described drilling and hanging net mechanism comprises rotating base 6, the rotating shaft 7 that is arranged on rotating base 6 upper ends and the drilling and hanging net device that is arranged on rotating shaft 7 upper ends, and described drilling and hanging net device consists of mechanical arm base 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com