Novel installation and construction method for hollow concrete partition boards

A construction method and technology of partition wall panels, which are applied in the direction of walls, building components, buildings, etc., can solve the problems of large volume, heavy weight, and installation of concrete hollow partition wall panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

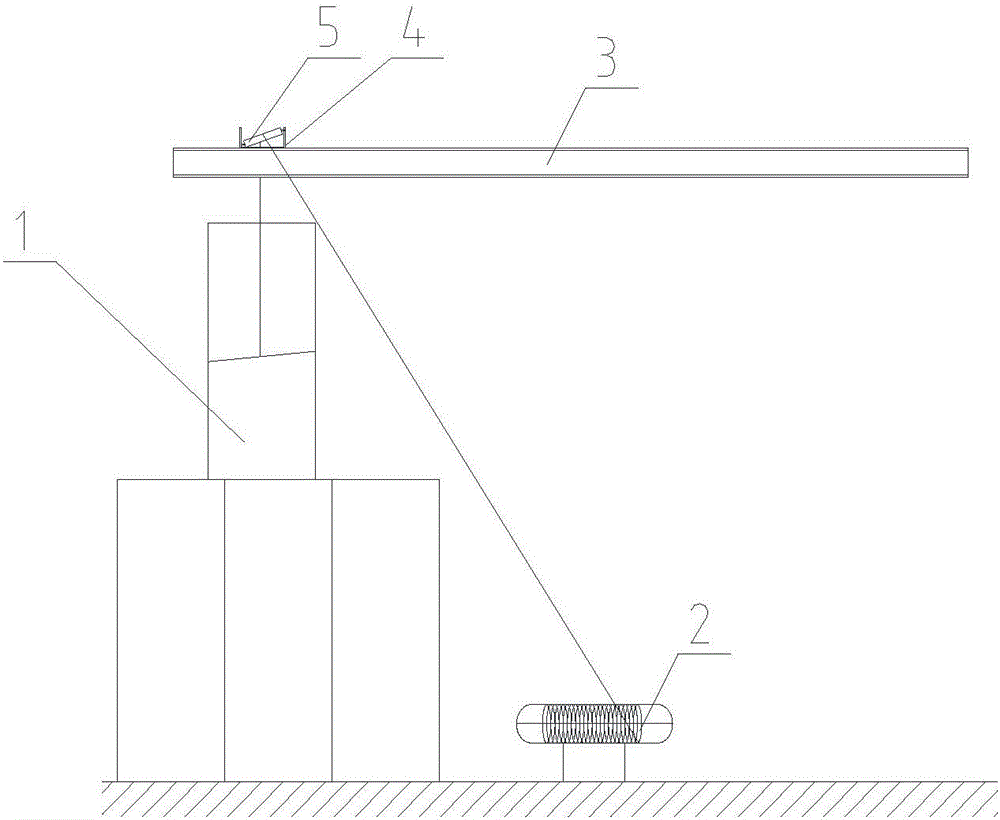

[0029] Such as figure 1 Shown: the present invention provides a kind of novel concrete hollow partition board installation construction method, comprises the following steps:

[0030] A. The partition board 1 is in place, the partition board here is a large concrete hollow partition board,

[0031] Laying out, popping up and down the double-thickness line on the axis of installing the partition wall panel 1, and transporting the partition wall panel 1 to the construction site at the same time;

[0032] According to the design specifications, cut the partition board 1, and the cutting can be done with an ordinary hand-held electric saw;

[0033] Place cement mortar on the building foundation, and place the partition board 1 to be installed on the building foundation;

[0034] Apply cement mortar on the edge of the partition wall panel 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com