Connector with rotation-stop nuts, and installation method thereof

A technology of anti-rotation nut and connector, which is applied in the field of structural parts, can solve the problems that the connection reliability of high-strength threaded steel bars or steel rods cannot be guaranteed, the reliability and service life of the anchoring structure can be reduced, and the development requirements of prestressed engineering cannot be met. To achieve the effect of reducing anchorage failure, improving reliability and effectiveness, and improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

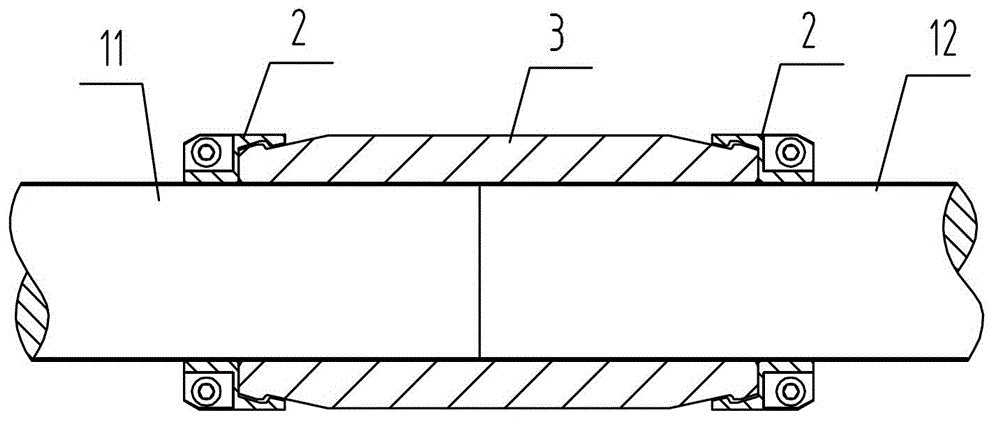

[0035] Embodiment 1: A connector with a stop nut

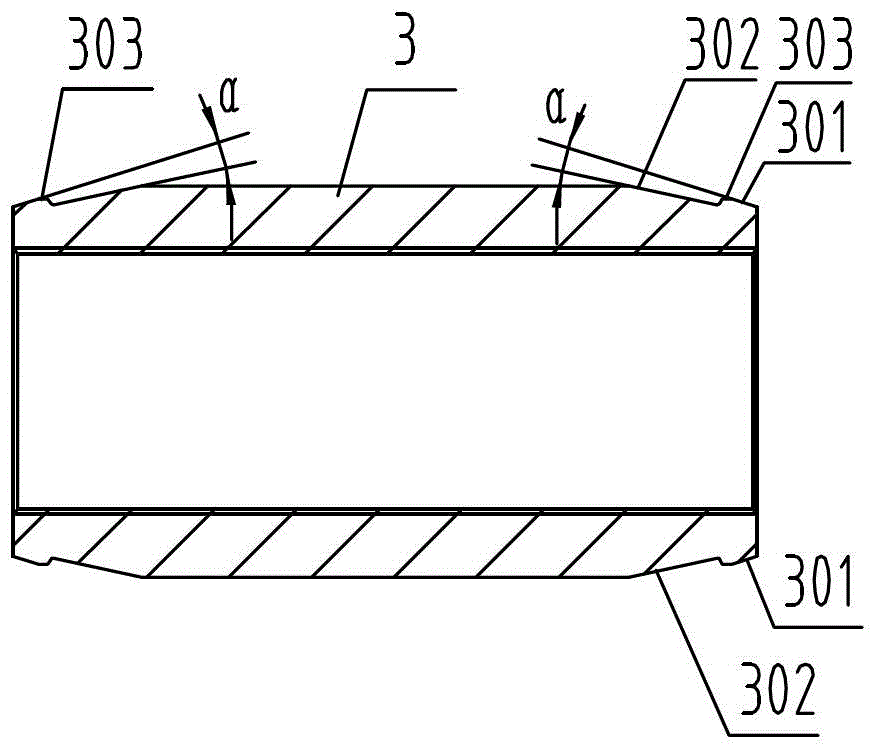

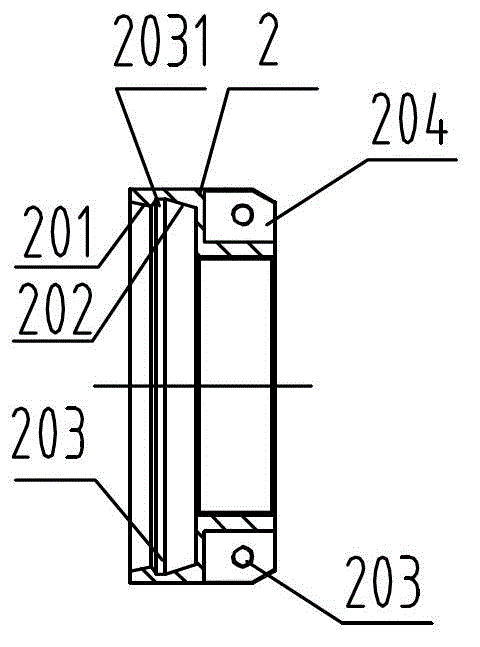

[0036] like figure 1 As shown, the connector with stop nuts includes a connector body 3 and stop nuts 2 installed at both ends of the connector body. The two ends of the connector body 3 are double cones, and the first cone at the end The angle α between the surface 301 and the second tapered surface 302 is 0~10o, and there is a ring-shaped protruding detent key 303 on the end of the second cone surface 302, and the outer cone surface of the detent key on the first cone surface 301 ( see figure 2 ), the inner hole of the connector body 3 has a continuous full thread that matches the high-strength threaded steel bar or steel bar; such as image 3 , Figure 4-1 to Figure 4-3 As shown, the anti-rotation nut 2 is a Haval nut split in two halves, the inner hole of the anti-rotation nut has a thread that matches the high-strength threaded steel bar or steel rod, and one end of the anti-rotation nut 2 has a The positioning groo...

Embodiment 2

[0039] Embodiment 2: A method for installing a connector with a stop nut, which includes the following steps:

[0040] A. Screw-in connector body

[0041] Screw the connector body 3 onto one end of the threaded steel bar or steel rod 11 to be connected;

[0042] B. Reverse screw-on connector body

[0043] Close the end face of another threaded steel bar or steel rod 12 that needs to be lengthened and the end face of the threaded steel bar or steel rod 11 that has been screwed on the connector body 3 on the same axis, and reversely screw the connector body 3 to Mark the position to complete the installation of the connector body 3;

[0044] C. Install the stop nut

[0045] Fasten the Haval type anti-rotation nut to the threaded steel bars or steel rods on the outer sides of the connector body 3, use the inner thread of the anti-rotation nut to rotate the anti-rotation nut to the connector, when the positioning groove 203 of the annular double inner cone surface When fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com