Hub, sliding sleeve and synchronous device, as well as method for producing hub and method for producing sliding sleeve

A technology for sliding sleeves and synchronous equipment, which is applied in the field of manufacturing sliding sleeves and manufacturing hubs, which can solve the problems of troublesome sliding sleeves and delay the manufacturing process of sliding sleeves, and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

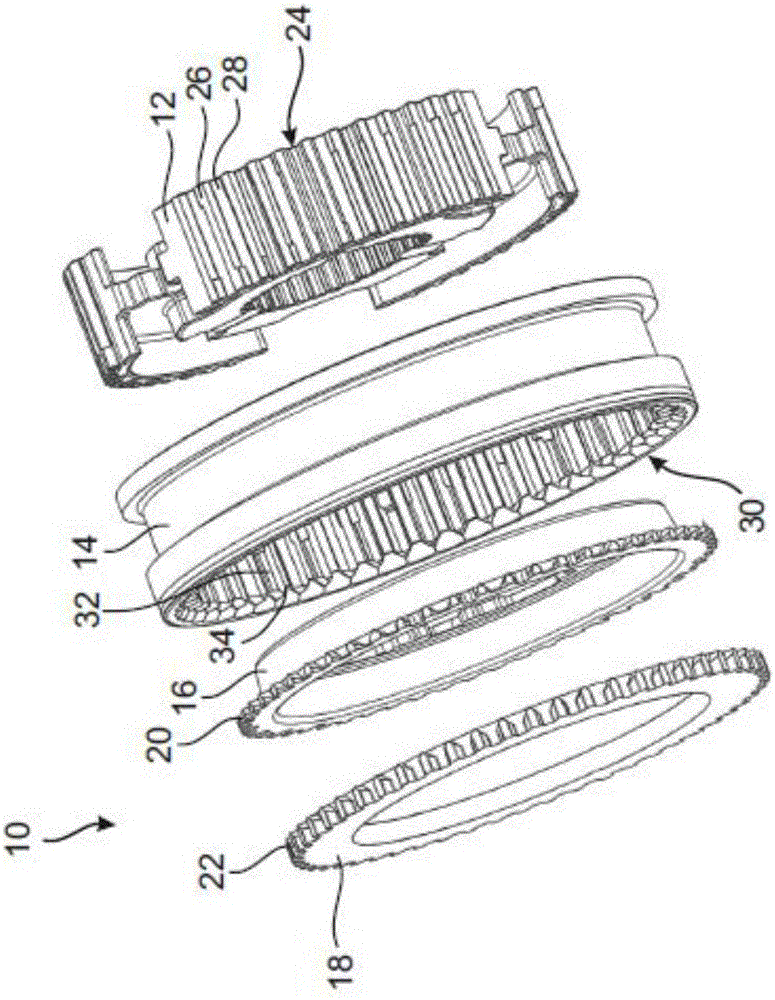

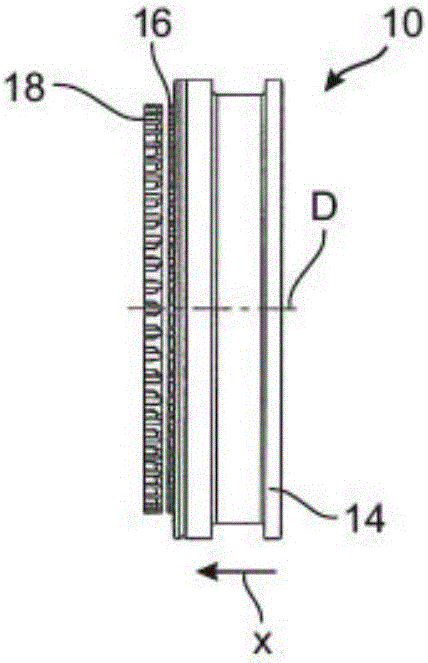

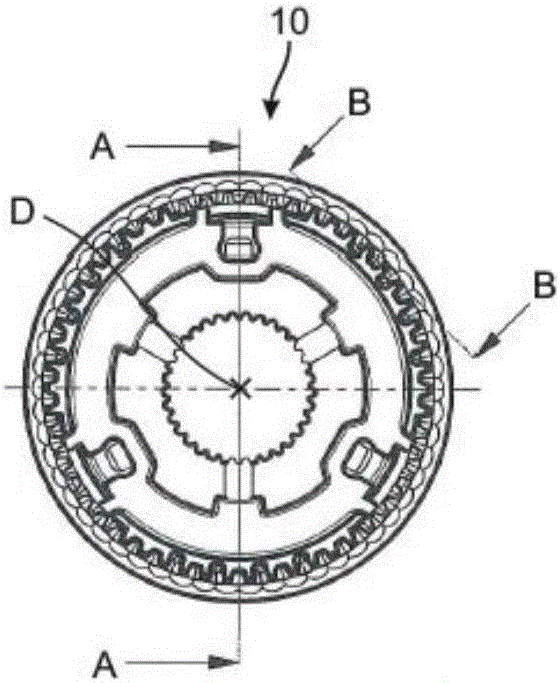

[0045] figure 1 A part of a synchronization device 10 for a gearbox of a motor vehicle is shown.

[0046] The synchronization device 10 comprises a disk-shaped hub 12 , which is seated in a rotationally fixed manner on a gear shaft and rotates about an axis of rotation D in the circumferential direction. Furthermore, the synchronization device 10 has a substantially annular sliding sleeve 14 which is arranged displaceably in the axial direction and is coupled to the hub 12 in a rotationally fixed manner. Furthermore, the synchronization device 10 has a synchronization ring 16 and a clutch body 18 which is part of an escape wheel (not shown here) which can be shifted after the rotational movements of the clutch body 18 and the hub 12 have been synchronized.

[0047] For synchronizing the rotational movement, a synchronizing ring 16 is provided, via which a frictional connection can be established between the hub 12 and the clutch body 18 or the escape wheel. To this end, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com