A bearing oil injector and method of using the same

A bearing oil and injector technology, which is used in engine components, engine lubrication, conveying pipes/joints, etc., can solve problems such as shortening the service life of vehicle bearings, uneven bearing oil, waste of resources and the environment, and save maintenance. time, improve the effect of oil injection, and reduce the effect of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

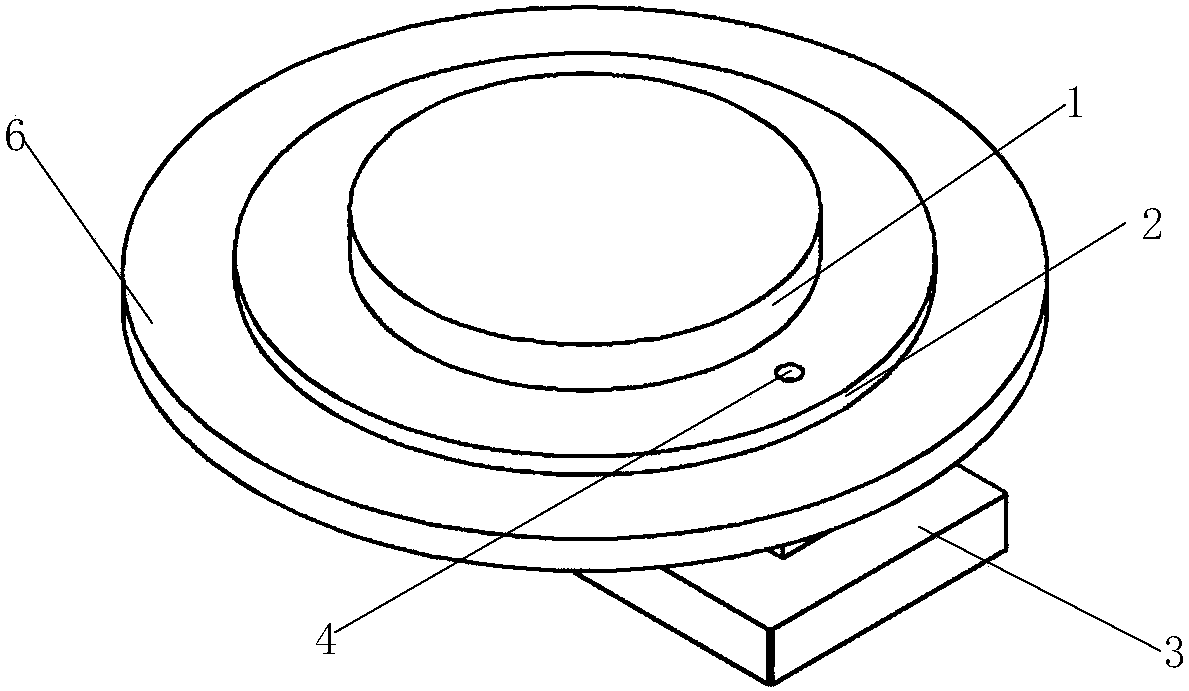

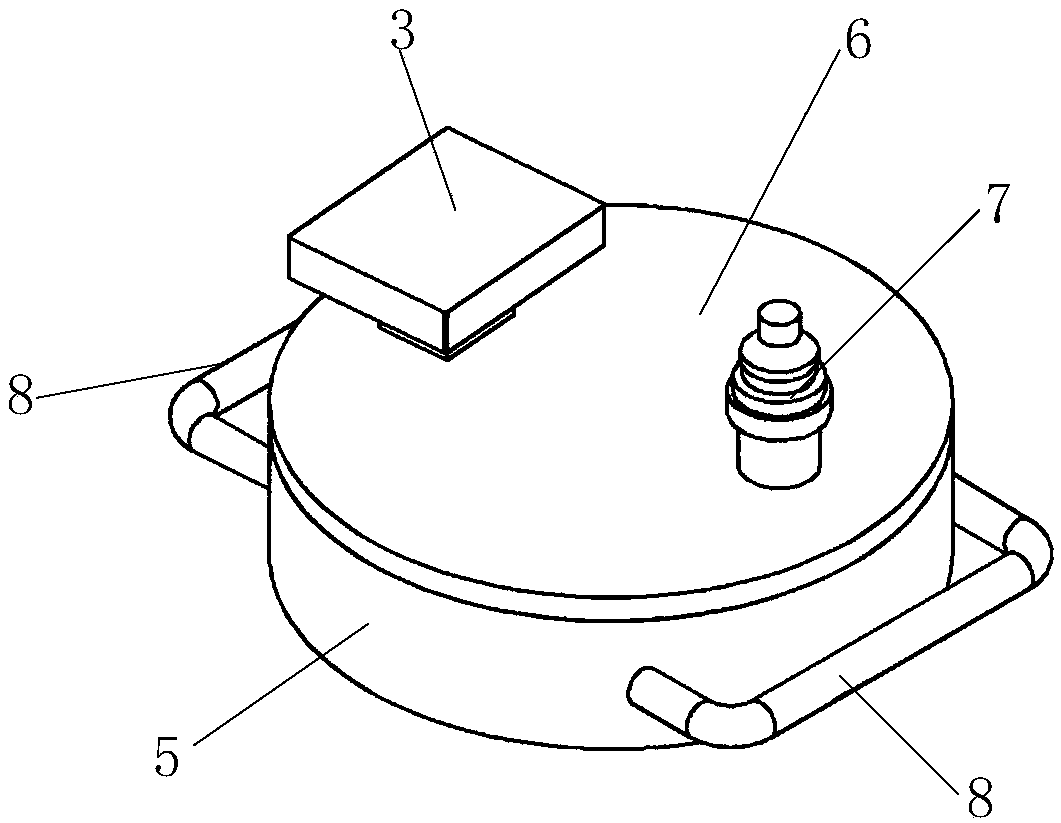

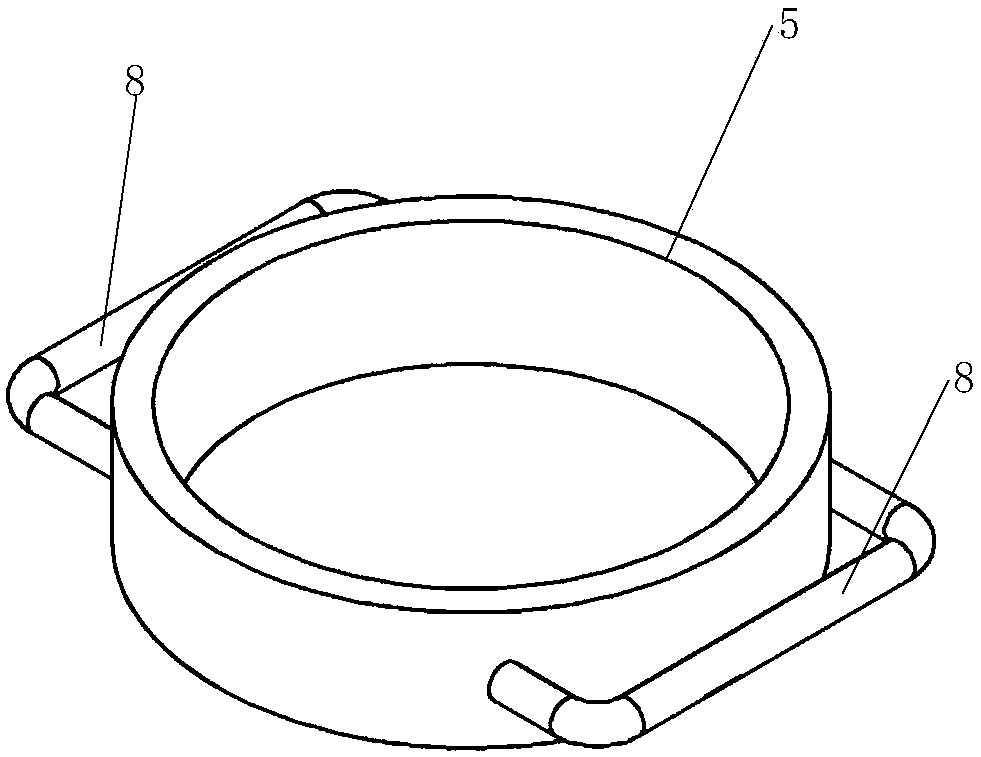

[0026] like Figure 1-4 As shown, a bearing oil filler includes a fixed plate 6, a second sealing shaft 1 for sealingly connecting with the inner ring of the bearing, a first sealing shaft 2 for sealingly connecting with the outer ring of the bearing and for accommodating The oil injection chamber 5 of the bearing; the one side of the fixed plate 6 is provided with an oil injection nozzle 7; connected sequentially; the first sealing shaft 2 is provided with an oil injection hole 4, the oil injection nozzle 7, the oil injection hole 4 and the oil injection chamber 5 communicate in sequence, the oil injection chamber 5 is a structure with two ends open, and the oil injection chamber 5 One end matches the fixed plate 6, and the fixed plate 6 is rotatably connected with one end of the oil injection chamber 5 through the first sealing shaft 2.

[0027] A further improvement is that the other side of the fixing plate 6 and the centers of the first sealing shaft 2 and the second sea...

Embodiment 2

[0034] A method for using a bearing oil filler, comprising the steps of:

[0035] A: Put the tapered roller bearing into the bearing oil filler and press it tightly;

[0036] B: After the bearing oil is pressurized, the bearing oil is filled through the pressure pipe and the oil injection nozzle on the fixed plate, and the oil injection chamber is rotated at the same time;

[0037] C: Stop filling the bearing oil and take out the tapered roller bearing.

[0038] A further improvement is that in the step A, the cylinder is used to compress one end of the bearing inner ring of the tapered roller bearing, and the other end of the bearing inner ring is pressed against the first sealing shaft.

[0039] Specifically, the cylinder is removed from the tapered roller bearing, and the tapered roller bearing is taken out.

[0040] Specific steps include:

[0041] A: Will figure 2 Put the bearing oil filler upside down, put the narrow end of the tapered roller bearing into the oil inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com