Test device for determining contact-impact deformation index of metal material

A metal material and deformation index technology, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. Determination of deformation index and other issues, to achieve the effect of low cost and simple test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

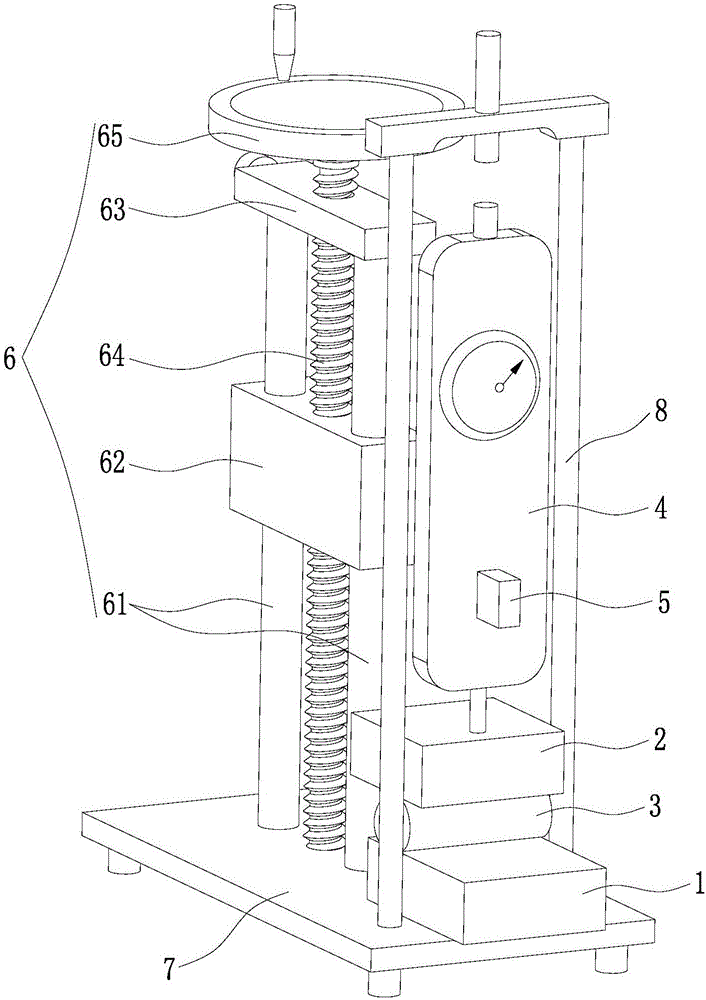

[0032] like figure 2 As shown, the present invention discloses a test device for determining the deformation index of a metal material contact collision, comprising a hard metal block A1, a hard metal block B2, a soft metal block C3, a thruster 4, a laser ranging sensor 5, a pushing device 6 and Base 7;

[0033] The pushing device 6 is installed on the base 7, the thrust meter 4 is installed on the pushing device 6, the pushing device 6 can push the thrust meter 4 to move up and down, and a thimble is installed at the lower end of the thrust meter 4;

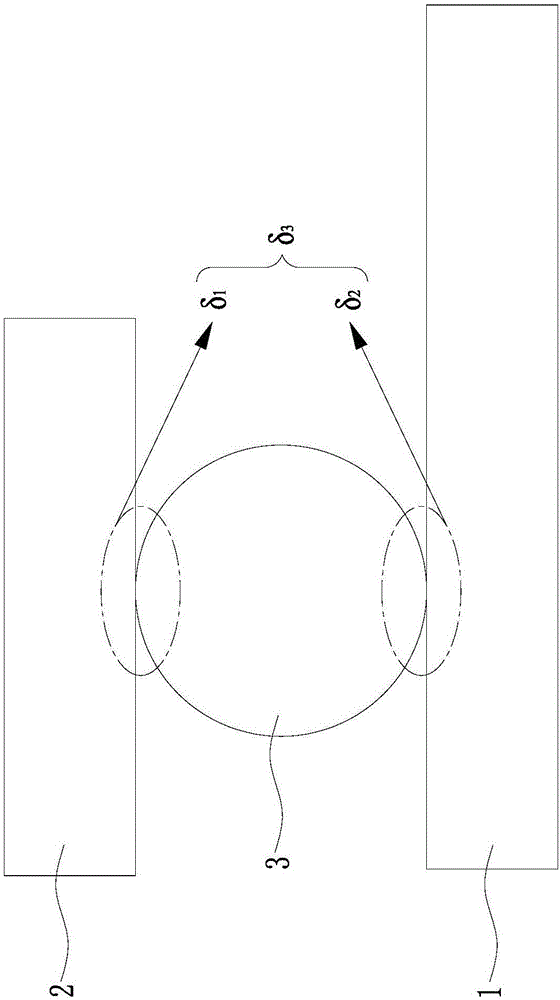

[0034] The hard metal blocks A1 and B2 are made of the same metal material, the hard metal block A1 is fixed on the base 7, the hard metal block B2 is located directly below the thimble 41 of the thrust gauge, and the soft metal block C3 is sandwiched between the hard metal blocks A and B During this period, the hard metal block A protrudes relative to the hard metal block B, the laser ranging sensor is installed on the thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com