SCR denitration catalyst life prediction method based on mass running data

A technology of denitration catalyst and operation data, which is applied in the field of life prediction of SCR denitration catalyst based on massive operation data, which can solve the problem of insufficient understanding of catalyst deactivation and wear, infrequent catalyst sample detection, and catalyst offline activity detection cycle unit. Maintenance cycle mismatch and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In the following, the present invention will be further explained in conjunction with the embodiments.

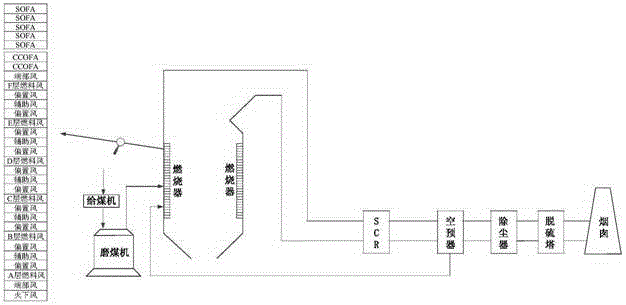

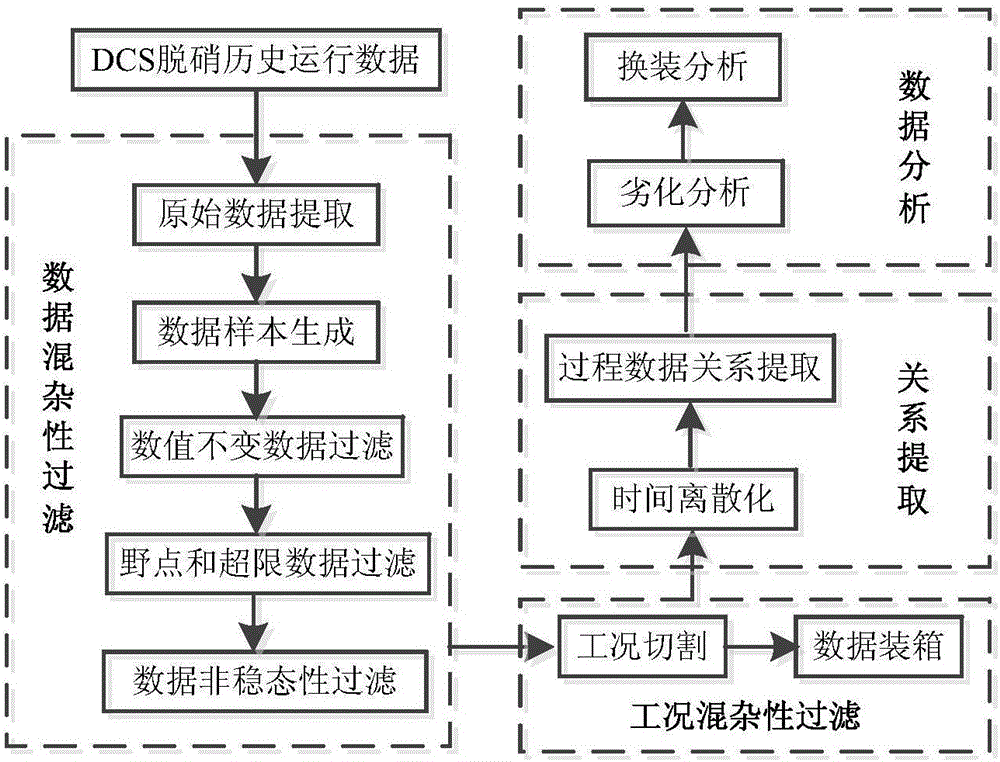

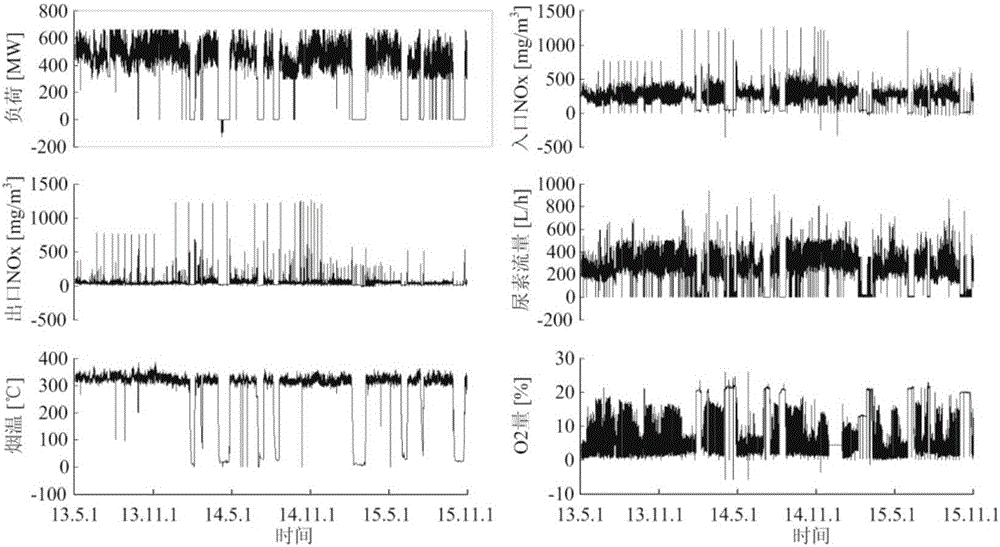

[0097] In order to solve the problem of catalyst life degradation analysis in coal-fired power plants, the present invention proposes a method for predicting the life of an SCR denitration catalyst based on massive operating data, such as figure 1 As shown, the method specifically includes the following steps: obtaining historical operating data from the DCS data source system; sorting the original data into a sample set according to time labels; filtering constant numerical data, outlier data, and over-limit data to ensure the basic analysis data Correctness; filter the non-steady state of the data to ensure the corresponding relationship between the input and output of the sample. The specific method can use the steady-state judgment algorithm to remove the non-steady state data, or use the average method to eliminate the influence of the non-steady state data; use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com